Introduction of vacuum equipments manufactured by ULVAC Group.

For more information on ULVAC products, purchase, and/or consideration, click here.

A thin film deposition system is a device used to form thin films on substrates such as silicon wafers.

ULVAC's small-scale experimental thin film deposition system offers high-precision deposition technology, making it ideal for research and development as well as small-scale production. Its compact design allows for efficient use even in limited spaces.

Type

Small Evaporation System

Vapor deposition is a technology that involves evaporating and vaporizing materials such as metals and oxides to deposit them onto a substrate surface, forming a thin film.

In the vapor deposition process, the target material is first heated and evaporated in a vacuum chamber using methods such as resistive heating, electron beam heating, or laser heating. The vapor then travels through the vacuum towards the substrate, where the vacuum environment minimizes diffusion. Upon reaching the substrate surface, the vapor condenses to form a uniform and high-quality thin film.

ULVAC's small-scale experimental vapor deposition systems offer high-precision thin film deposition technology, ideal for research and development as well as small-scale production. Their compact design allows for efficient use even in limited spaces.

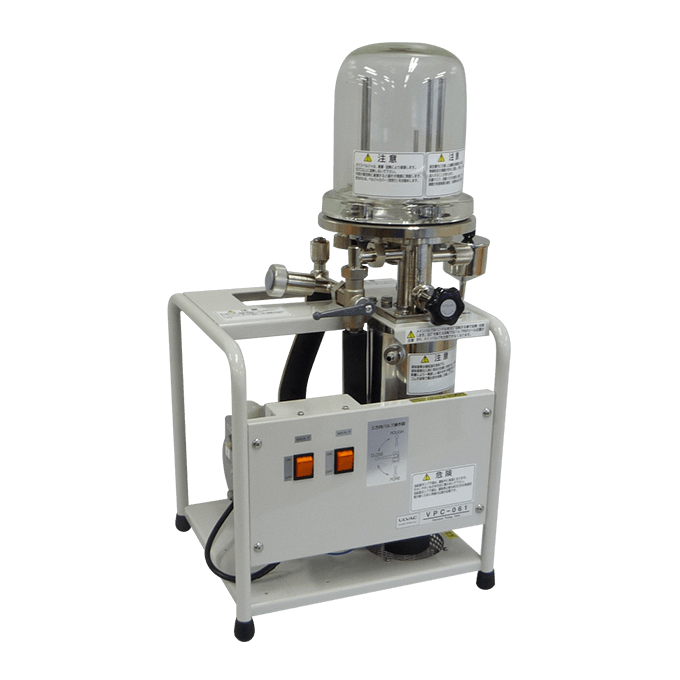

Small Evaporation System

Model: VPC-061

This compact vacuum evaporation system is a resistance heating type and low cost type, in which the necessary equipment such as Main pump, Sub pump, valve piping, electric system, pressure measurement port, etc. are compactly stored in a pipe frame.

Ideal for experiments such as basic research and development of small substrate size.

Small Evaporation System

Model: VPC-260F

Small-sized high-vacuum low cost exhaust equipment with resistance heating requiring compact storage, such as main pumps, backing pumps, valve piping, electrical systems and pressure measurement ports in pipe frames.

Ideal for experiments, such as basic research and development of small boards.

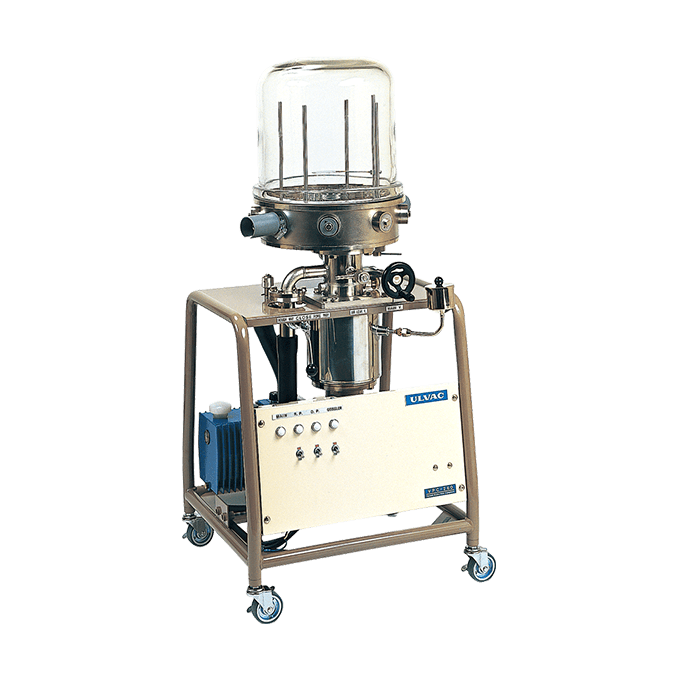

Small Evaporation System

Model: VPC-1100

It is a high-speed type vacuum deposition system by the resistance heating formula which stored compactly required apparatus, such as an oil diffusion pump, an oil rotary vacuum pump, Pirani gauge, valve piping, an electric system, and a pressure measurement port, in the mount, and has equipped belljar rise-and-fall equipment etc.

It is ideal for an experiment, such as basic research development of large substrate size.

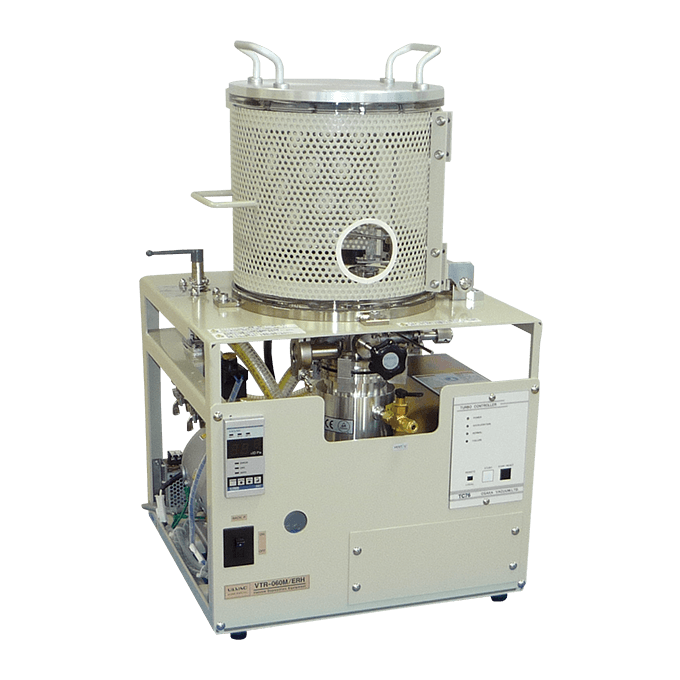

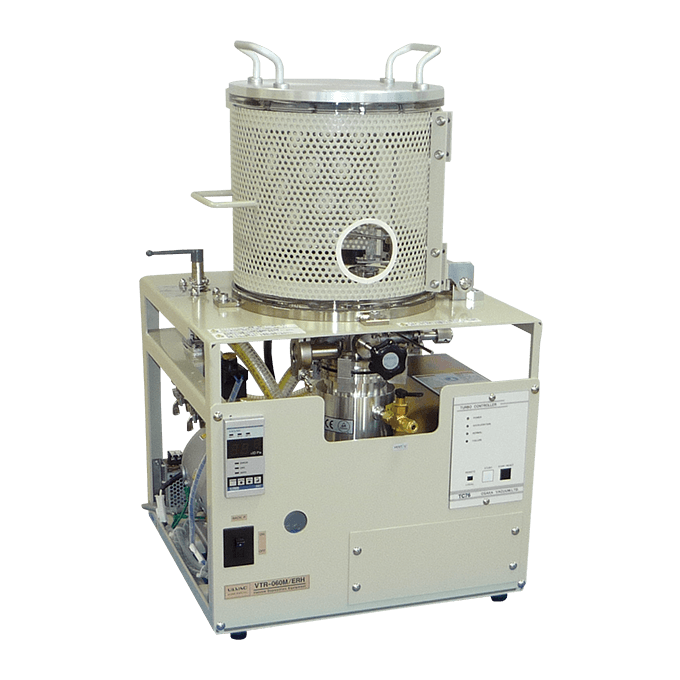

Small Evaporation System

Model: VTR-060M/ERH

It is a small-sized vacuum evaporation system with resistance heating type and low cost type, in which a turbo molecular pump and Sub pump are compactly stored in a frame.

Suitable for experiments such as basic research and development with clean exhaust.

Sputtering System

Sputtering is a type of physical vapor deposition (PVD) technology that involves ejecting atoms from a target material to form a thin film on a substrate.

The sputtering process begins by introducing an inert gas, such as argon, into a vacuum chamber and applying voltage to generate plasma. In this plasma, argon ions collide with the target material, causing atoms to be ejected in a process known as "sputtering." These ejected atoms then travel to the substrate, where they form a uniform and high-quality thin film.

ULVAC's small-scale experimental sputtering systems offer high-precision thin film deposition technology, ideal for research and development as well as small-scale production. Their compact design allows for efficient use even in limited spaces.

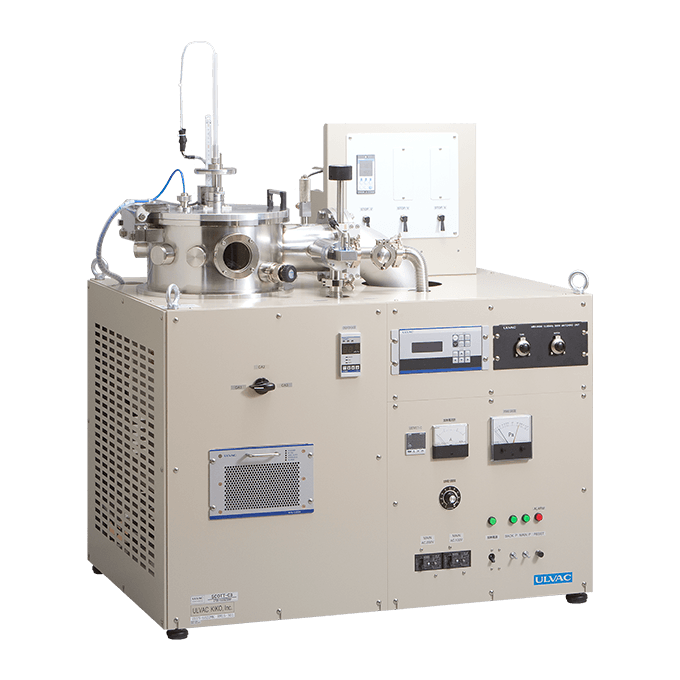

Sputtering System

Model: VTR-151M/SRF

Small-sized high-frequency sputtering device with an RF power supply.

Ideal for basic research and development experiments because of the deposition capabilities for metals, semiconductors and insulators.

Sputtering System

Model: RFS-201

Small-sized high-frequency sputtering device with an RF power supply.

Ideal for basic research and development experiments because of the deposition capabilities for metals, semiconductors and insulators.

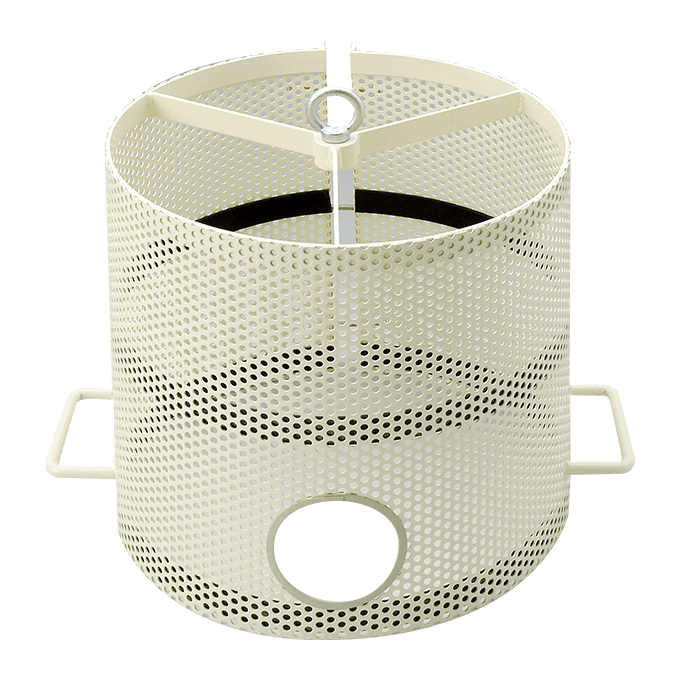

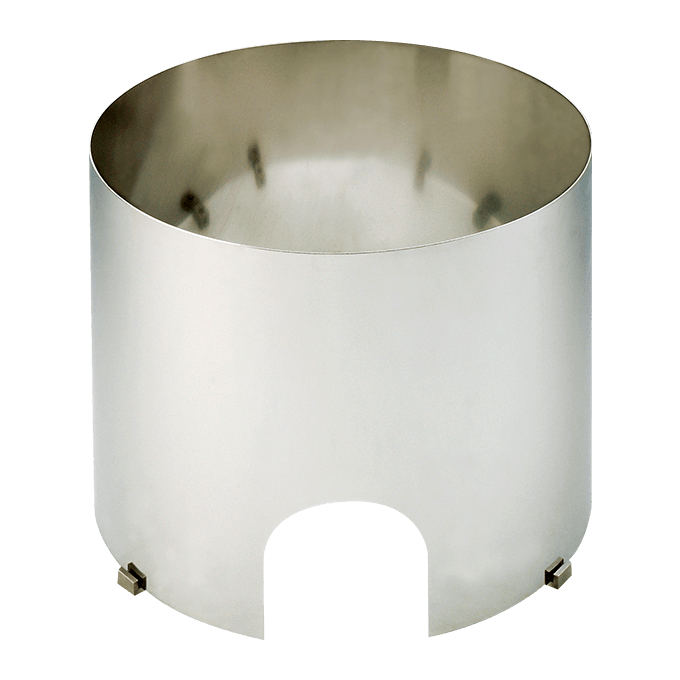

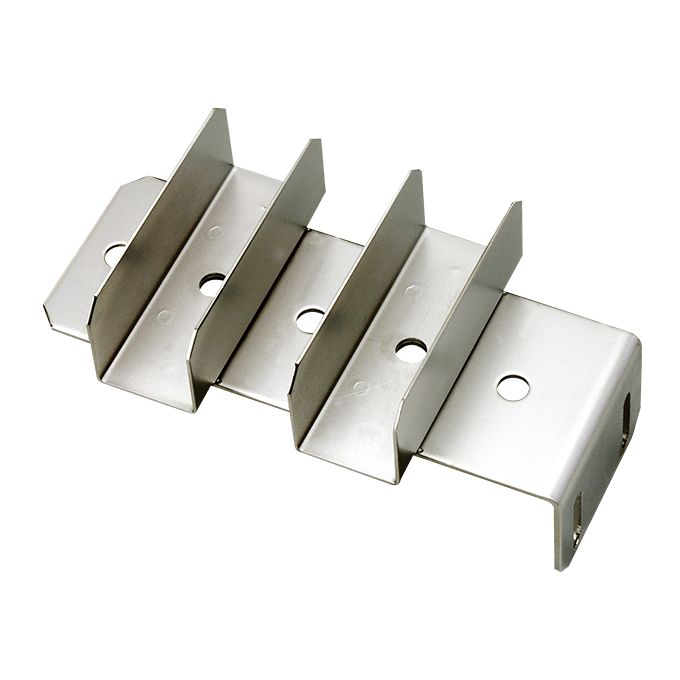

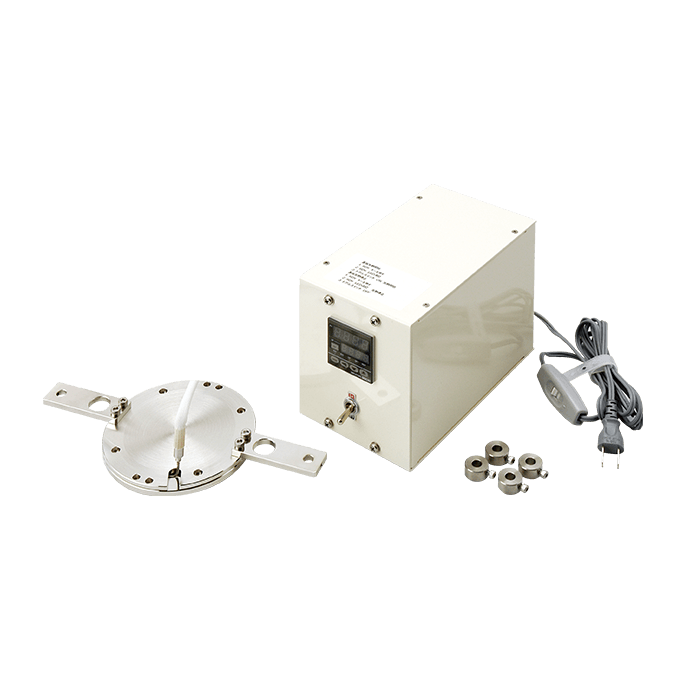

Film Forming Equipment Optional Parts

These are options for ULVAC's deposition equipment.

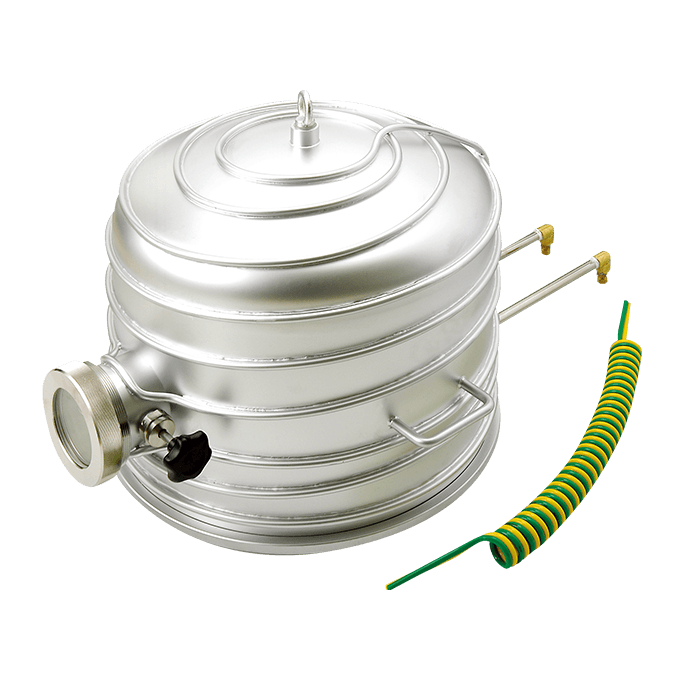

Film Forming Equipment Optional Parts

Metal bell jar (with water cooling tube)

It is an object for overheating prevention of s bell jar.

Film Forming Equipment Optional Parts