Sputtering System

For more information on ULVAC products, purchase, and/or consideration, click here.

Sputtering is a type of physical vapor deposition (PVD) technology that involves ejecting atoms from a target material to form a thin film on a substrate.

The sputtering process begins by introducing an inert gas, such as argon, into a vacuum chamber and applying voltage to generate plasma. In this plasma, argon ions collide with the target material, causing atoms to be ejected in a process known as "sputtering." These ejected atoms then travel to the substrate, where they form a uniform and high-quality thin film.

ULVAC's small-scale experimental sputtering systems offer high-precision thin film deposition technology, ideal for research and development as well as small-scale production. Their compact design allows for efficient use even in limited spaces.

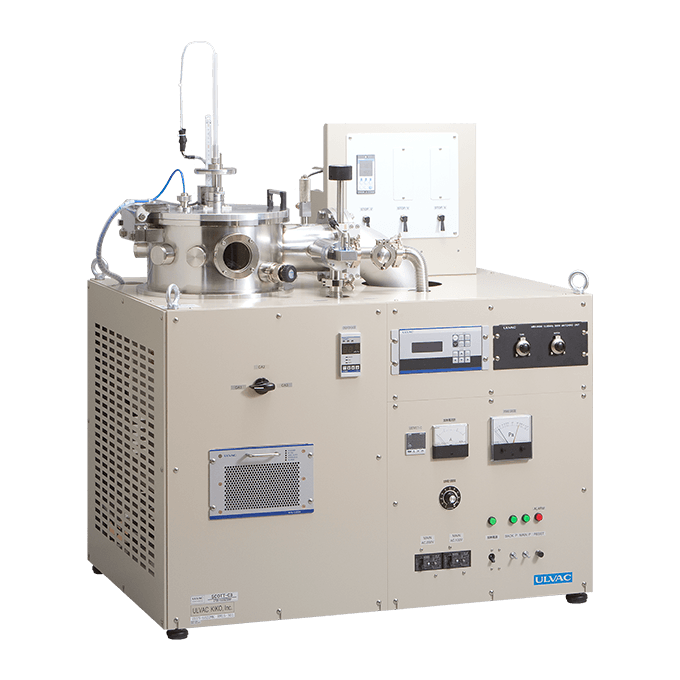

Sputtering System

Sputtering System

Model: VTR-151M/SRF

Small-sized high-frequency sputtering device with an RF power supply.

Ideal for basic research and development experiments because of the deposition capabilities for metals, semiconductors and insulators.

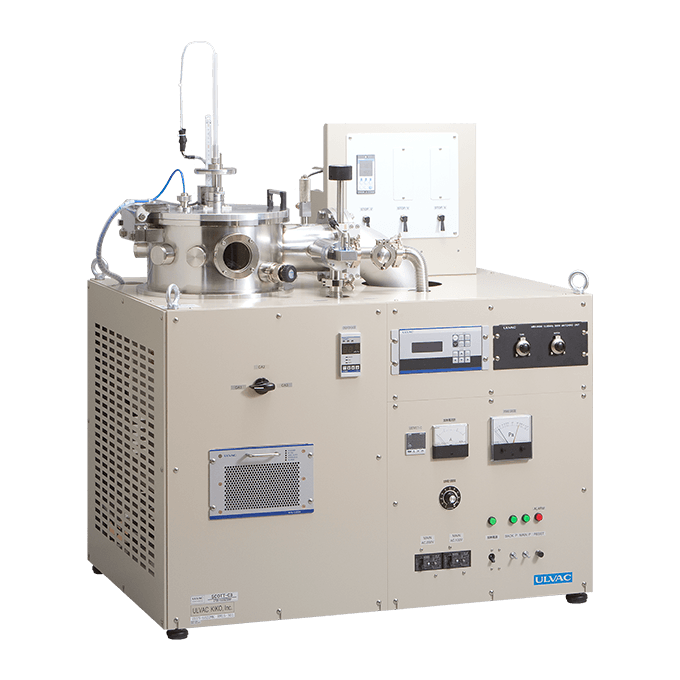

Sputtering System

Model: RFS-201

Small-sized high-frequency sputtering device with an RF power supply.

Ideal for basic research and development experiments because of the deposition capabilities for metals, semiconductors and insulators.