YMV series frame unit, which is for combining a ULVAC's mechanical booster pump with an oil-sealed rotary vacuum pump, can be selected from four types according to the exhaust volume.

The independent frame design emphasizes the maintainability of the pump, making them ideal for use in production facilities.

It has the same concept as the conventional mechanical booster pumping unit YM-VD and can also install an oil-sealed rotary vacuum pump VS series.

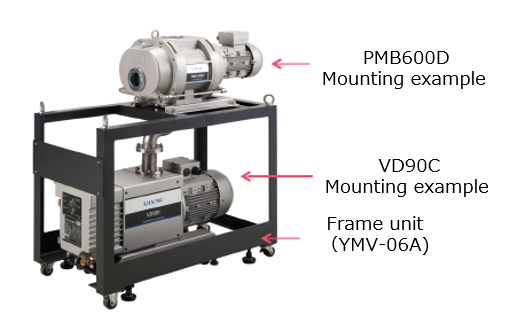

Basic Configuration.

Basic Configuration.

① Frame Unit [With bellows piping, caster, and adjuster]

② Mechanical booster pump(Sold separately)

③ Oil-sealed rotary vacuum pump(Sold separately)

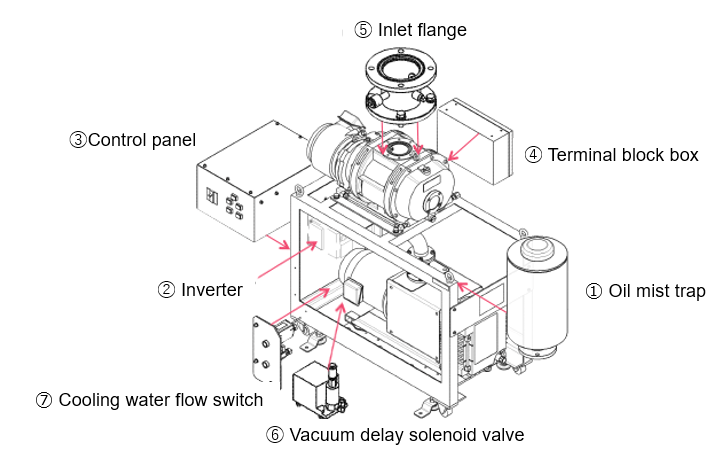

Options(Sold separately)

① Oil mist trap

② Atmospheric pressure operation [With inverter]

③ Control panel

④Terminal block Box

⑤ Inlet port flange

⑥ Delayed vacuum solenoid valve

⑦ Cooling water flow switch

Please select the pump with the desired pumping speed and options as required.

(※Note: Pumps and optional parts are sold separately.)

Precautions when ordering.

- YMV series is a frame unit for mechanical booster pumps.

A mechanical booster pump and an oil rotary vacuum pump are sold separately. - Refer to the single catalog for the specifications of the mechanical booster pump and the oil rotary vacuum pump. Single option can be added.

(※Select the atmospheric pressure operation (inverter) from YMV options.)

Examples of YMV series and installed pumps.

| Frame unit(YMV series) | Mechanical booster pump | Oil rotary vacuum pump |

|---|---|---|

| YMV-01A | PMB100D ※ | VD30C ※ |

| PMB-001C(M) | ||

| YMV-03A | PMB300D ※ | VD40C ※ |

| PRC-003A | ||

| PMB-003C(M) | ||

| YMV-06A | PMB600D ※ | VD60C ※ |

| PRC-006A | ||

| PMB600D ※ | VD90C ※ | |

| PRC-006A | ||

| YMV-12A | PMB600D ※ | VS1501 ※ |

| PRC-006A | ||

| PMB600D ※ | VS2401 ※ | |

| PRC-006A | ||

| PMB1200D ※ | VS1501 ※ | |

| PRC-012A | ||

| PMB1200D ※ | VS2401 ※ | |

| PRC-012A | ||

| YMV-18A | PRC-018A | VS2401 |

【Note】

If the product is used in a clean room, mechanical booster pumps with a canned motor specification PRC series is recommended.

YMV -18 A is equipped with PRC-018A. We will provide it according to your request.

Options.

① Oil Mist Trap.

It removes oil smoke from the oil rotary vacuum pump.

When operating continuously at high suction pressure or repeatedly pumping air to vacuum, select a mist trap for high load.

| Oil rotary vacuum pump model | for low to medium load 10,000Pa or less |

for high load 10,000Pa or more |

|---|---|---|

| VD30C/VD40C | TM201 | TM401 |

| VD60C/VD90C | TM401 | TM-2 or TM-2F |

| VS1501 | TM-3 or TM-3F | |

| VS2401 | TM-4 or TM-4F | |

If a flange mount instead of an umbrella type for exhaust port is desired, select the model with F.

② Atmospheric pressure operation ( inverter).

An optional YMV inverter is used to drive the mechanical booster pump at atmospheric pressure.

Frame Mounting type (sold separately from the pump).

【Note】A pump integrated inverter, which is a mechanical booster pump single option, cannot be selected.

| MBP installation (with mounting seat) | Separate Type |

|---|---|

| No option settings | I2(for YMV, excluding PMB100D) MBP water cooling setting INV、for 200 to 240V |

| No option settings | I4(for YMV, excluding PMB100D) MBP water cooling setting INV, for 380 to 480V |

| No option settings | A2(for YMV, only PMB100D, others are for special model) MBP water cooling setting INV, for 200 to 240V |

| No option settings | A4(for YMV, only PMB100D, others are for special model) MBP water cooling setting INV, for 380 to 480V |

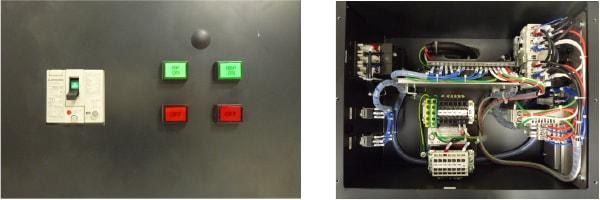

③ Control panel.

This control panel has ON/OFF switches for the oil rotary vacuum pump and the mechanical booster pump.A motor breaker and circuit protector are built-in.

※ A motor breaker and circuit protector are built-in.

④ Terminal block Box.

It is a box with a terminal block that combines the cable connection of an oil rotary vacuum pump and a mechanical booster pump in one place.It is not used together with the control panel.

※ Different control panels are available depending on the pump selection (Model and voltage).

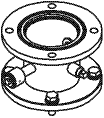

⑤ Inlet port flange.

It is a short pipe which is attached to the inlet port of the mechanical booster pump.

Φ18 gauge port, leak port, and 1/4 B socket are included.

※Selected from 100 (VG 50), 300 D/600 D (VG 80), 1200 (VG 100), and 1800 (VG 150)

⑥ Delayed vacuum solenoid valve.

This is a solenoid valve that breaks the vacuum (Leak) to prevent the backflow of oil from the oil rotary vacuum pump to the inlet port side when it is stopped.

※Select from DC24V/AC200V/AC220V/AC380V/AC400V/AC415V/AC440V.

When using a delayed vacuum solenoid valve, a 1/4 B socket is required for piping.It is recommended to purchase in combination with an inlet port flange, option 5.

⑦ Cooling water flow switch.

It monitors the amount of cooling water in the pump to prevent problems due to insufficient cooling water.

※※DC24V specification.

Specifications of the frame unit YMV series.

|

Stand unit *1 |

YMV-01A | YMV-03A | YMV-06A | |||

| Bellows, caster with adjuster | ||||||

| Recommended pump *2 | Mechanical booster pump | PMB100D | PMB300D | PMB600B | ||

| Oil rotary pump | VD30C | VD40C | VD60C | VD90C | ||

| Max. pumping speed. m3/hr (L/min) | 50Hz | 95(1,580) | 250(4,100) | 450(7,500) | 500(8,330) | |

| 60Hz | 115(1,900) | 290(4,800) | 520(8,670) | 600(10,000) | ||

| Max. suction pressure Pa | 50Hz | 8.5×103 | 7.0×102 | 1.0×103 | 1.3×103 | |

| 60Hz | 4.5×103 | 7.0×102 | 10×103 | 1.1×103 | ||

| Ultimate pressure Pa *3 | 4.0×10-1 | |||||

| Cooling water | Cooling water method *4 | Air cooled | Air cooled/ water cooled | |||

| Primary side pressure MPaG | - | 0.3 | ||||

| Inlet/ outlet differential pressure MPaG | - | 0.05 | ||||

| Temperature ℃ | - | 5~30 | ||||

| Volume L/min | - | 2.0≦ | ||||

| Suction port JIS B 2290 | VG50 | VG80 | ||||

| Exaust port JIS B 2290 | VG40 | |||||

| Weight kg | 145 | 175 | 260 | 285 | ||

| Option | Atmospheric operation (inverter) *5 | 12 | For PMB100D | For PMB300D | For PMB600D | |

| 14 | For PMB100D | For PMB300D | For PMB600D | |||

| Oil mist trap | TM201/TM401 | TM401/TM-2(F) | ||||

| Contol box *6 | For PMB100D+ VD30 | For PMB300D+VD40C | For PMB600D+VD60C | For PMB600D+VD90C | ||

| Terminal box | For PMB100D+ VD30C | For PMB300D+VD40C | For PMB600D+VD60C | For PMB600D+VD90C | ||

| Suction flange *7 | For PMB100D | For PMB300D/PMB600D | ||||

| Vacuum delay selenoid valve *8 | Common (Select from DC24V/AC200C/AC220V/AC380V/AC400V/AC415V/AC440V) | |||||

| Cooling water flow switch *9 | ー | For PMB300D+VD40C/PMB600D+VD60C/PMB600D+VD90C | ||||