Turbo Molecular Pump Model: UTM-MI

ULVAC

For more information on ULVAC products, purchase, and/or consideration, click here.

Features

- Controller integrated with the pump body

No wiring work between pump body and controller. - Free mounting direction

Free mounting direction makes the system design flexible. - Wide range and high flow for the light processes.

- Pump rotation variable from 25% to 100%

Enabling the pressure adjustment in a chamber by changing the rotation speed. - High durability and safety

Safety confirmation tests are passed, such as air rushing-in test and touch down test.

Applications

- Main vacuum pumping system for equipment

- Semiconductor equipmen

- Evaporator,Sputtering syste

- Analytical equipment,Experimental device and etc. - Main vacuum pumping system for the light processes that do not generate side reaction products.

- Replacement from oil diffusion pumps

- General use for high vacuum evacuation system.

Specifications

| Model | UTM1200A | UTM1600A | UTM2300A | UTM3400A | ||||||||

| Inlet port | VG 150 |

ISO 160F |

VG 200 |

VG 250 |

ISO 200F |

ISO 250F |

VG 250 |

ISO 250F |

VG 300 |

VG 350 |

ISO 320F |

|

| Outlet port | KF40 | |||||||||||

| Ultimate pressure *1 |

10-7 Pa | |||||||||||

| Pumping speed *2*3 |

N2 | 1030 L/s | 1400 L/s | 2100 L/s | 3200 L/s | |||||||

| Ar | 980 L/s | 1330 L/s | 2000 L/s | 3100 L/s | ||||||||

| H2 | 660 L/s | 750 L/s | 1380 L/s | 2100 L/s | ||||||||

| Comp ression rate |

N2 | 2×108 | ≧ 1×108 | ≧ 1×109 | ||||||||

| He | 7×103 | 5×103 | 1×105 | |||||||||

| H2 | 8×102 | 9×102 | 6×103 | |||||||||

| Max inlet pressure *4 |

26 Pa | 4.5 Pa | 7 Pa | |||||||||

| Max outlet pressure *4 |

266 Pa | 200 Pa | 270 Pa | |||||||||

| Rotation speed | 37200 min-1 | 33700 min-1 | 27600 min-1 | |||||||||

| Speed variation | Speed is variable between 25% and 100% of the rated speed.( set as 0.1%) | |||||||||||

| Start-up time | ≦ 8minutes | ≦ 9minutes | ≦ 16minutes | |||||||||

| Mounting position |

In any desired direction | |||||||||||

| Surface treatment *5 |

None | |||||||||||

| Commun ication |

Contact | D-sub 25 pin female Contact input and output signal | D-sub 37 pin female Contact input and output signal | |||||||||

| Serial | Serial connecter RS232C/RS485 | D-sub 9 pin male RS232C/RS485 | ||||||||||

| Controller | Compo sition |

Pump with integrated controller | ||||||||||

| Input electric power |

Single phase AC200 〜240V ±10%( 50/60Hz ±2Hz) | |||||||||||

| Max power |

0.75kVA | 1.2kVA | ||||||||||

| Cooling method | Water cooled | |||||||||||

| Cooling water *6 |

Flow rate |

3 - 4 L/min | ||||||||||

| Pressure | 0.2 - 0.4M PaG | |||||||||||

| Noise | 57 dB(A) | 60 dB(A) | ||||||||||

| Weight | 43 kg | 41 kg | 56 kg | 94 kg | ||||||||

| Recommended backing pump *7 |

≧ 600L/min | ≧ 1500L/min | ||||||||||

| Applicable standard | CE, TUVus | |||||||||||

| Standard accessories | O-ring(Only VG), Dust cap(Outlet port), Remote-control Connector, Instruction manual(CD-ROM) | |||||||||||

| Select parts |

AC Cable | AC Conector / AC Cable(5m/10m/15m/20m) | ||||||||||

| Special bolt for fixing pump |

M10/ M12 | |||||||||||

| Special bolt for fixing pump |

Need(M10) *8 | Not Need *8 | ||||||||||

| Option | Gas purge adaptor (KF10) | |||||||||||

*1 digit number is expressed.

*2 Without a protective net.

*3 Calculated values : UTM2300A and UTM3400A

*4 Max inlet pressure and Max outlet pressure cannot be satisfied at same time.

*5 Do not flow reactive gas and corrosive gas. Please contact us when using other gases.

*6 Not condensing

*7 When evacuating 30SCCM

*8 Grade of bolts,Fixing method and etc. are subject to various conditions. Please contact

us for the detailed information.

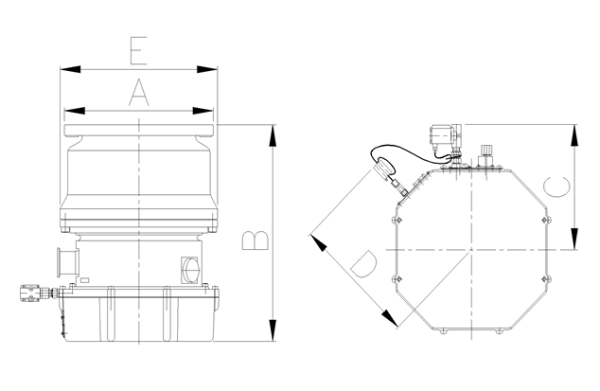

Dimension drawing

- Dimensions

(mm)

| A | B | C | D | E | ||

| UTM1200A | VG150 | 235 | 439 | 218 | - | 285 |

| ISO160F | 225 | 442 | 218 | - | 285 | |

| UTM1600A | VG200 | 300 | 374 | 218 | - | 285 |

| ISO200F | 285 | 374 | 218 | - | 285 | |

| VG250 | 350 | 374 | 218 | - | 285 | |

| ISO250F | 335 | 374 | 218 | - | 285 | |

| UTM2300A | VG250 | 350 | 376 | 233 | 245 | 310 |

| ISO250F | 335 | 376 | 233 | 245 | 310 | |

| UTM3400A | VG300 | 400 | 462 | 233 | 245 | 360 |

| VG350 | 450 | 462 | 233 | 245 | 360 | |

| ISO320F | 425 | 467 | 233 | 245 | 360 | |

Note)The position and phase of outlet, gas purge port,

cooling water valve and cooling water valve connector are different to types.

Please contact us for the details information.