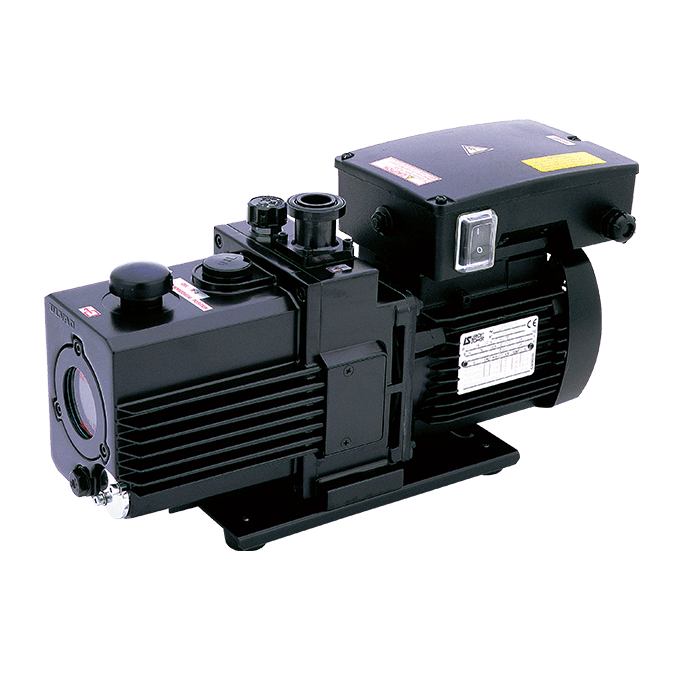

Oil Rotary Vacuum Pump

High Functionality Type

Model: GLD-040

ULVAC

For more information on ULVAC products, purchase, and/or consideration, click here.

Features

- The two-stage exhaust system has lower pressure (good vacuum) than the one-stage exhaust system.

- Low noise and low vibration.

- The backflow prevention mechanism prevents oil from flowing back to the vacuum chamber when it is stopped due to a power failure.

- The exhaust speed is stable due to the installation of the forced oil supply mechanism.

- Operation from atmospheric pressure is possible.

- Easy connection by internal components knock pins and maintenance by flange motor

Applications

- Chemical, science experiment, Analyzer and Laser system.

- Backing pumps for the electronic microscope.

- Semiconductor equipments, sputtering equipments, vacuum evaporation equipments.

- Vacuum dryer, freeze dryer.

Specification

| Unit | 50Hz | 60Hz | ||

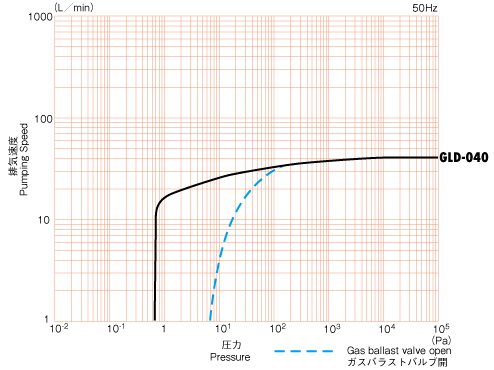

| Actual pumping speed | L/min | 40 | 48 | |

| Ultimate pressure※1 | G.V.Closed | Pa | 0.67 | |

| G.V.Open | 6.7 | |||

| Motor※2 | Single phase, 100V - 120V/200 - 240V 200W, 4P, Capacitor start/run | |||

| Full load current | A | 4.2 (100V), 4.4 (110V) 4.6 (115V), 5.05 (120V) 2.1 (200V), 2.2 (220V) 2.3 (230V), 2.6 (240V) |

3.6 (100V), 3.4 (110V) 3.4 (115V), 3.6 (120V) 1.8 (200V), 1.7 (220V) 1.7 (230V), 1.8 (240V) |

|

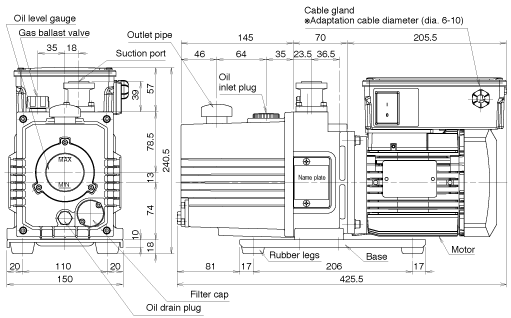

| Oil capacity | mL | 550 - 800 | ||

| Recommended oil | R-2 | |||

| Weight | kg | 16 | ||

| Inlet port diameter | mm | KF-25 | ||

| Ambient temperature | ℃ | 7 - 40 | ||

| External dimensions | mm | 150(W) X 425.5(L) X 240.5(H) | ||

(In the case of measurement by McLeod gauge, the value is lower by an order of magnitude for pumps with an Ultimate pressure of 1.3 Pa or less.)

※2:Power supply plug and Power supply code are not included.

Corresponding certificate/Voltage

| Model | Applicable standard※ | CE Declartion of confirmity |

1Φ 100 - 120V |

1Φ 200 - 240V |

3Φ 200 - 240V |

3Φ 380 - 460V |

| GLD-040 | TUV・cTUVus | ✓ | ✓ | ✓ | - | - |

✓:Standard、○:Option、-:Not Applicable

※TUV Certification: A high-quality product that complies with European standards as assessed by an international third party that conducts product safety testing and certification.

※cTUVus Certification: A high quality product that complies with Canadian and US standards as assessed by an international third party that conducts product safety testing and certification.

Caution

|

1

|

Oil is deteriorated with operating, and becomes the factor of performance shortage.

A decrease and the dirt of oil are confirmed, and please regularly add and replace it. |

|

2

|

A backflow preventer is incorporated into the pump to prevent the oil from flowing back while the pump is stopped.

Please make a suction side into atmospheric pressure when the pump is stopped for a long time. |

|

3

|

If operation is performed at high pressure, oil mist is generated at the exhaust side.

|

|

4

|

It is not suitable for the pump if operation is performed continuously at a high evacuation pressure of 10kPa or more.

|

|

5

|

There is a risk of explosion. Never block the outlet or operate the pump with equipment mounted at the outlet side that blocks the passage of gas.

Otherwise, the internal pump pressure increases causing the pump to explode, the oil level gauge to protrude or the motor to be overloaded. |

|

6

|

Same parts of the pump are made by carbon.

Oil becomes black with wear-out powder of carbon parts, when operation is doing. But it doesn’t affect the performance and service life of the pump. |

|

7

|

This motor houses an automatic returning thermal protector, which may be activated in case of trouble.

The motor will restart automatically when the temperature goes down. If the thermal protector is activated, switch off the power immediately for safety reason. |

Dimension drawing

Pumping Speed Curves