Refrigerator Meets Vacuum Technology

Protect nutrients by preventing oxidation with a vacuum chilled

Protect nutrients by preventing oxidation with a vacuum chilled. 49 kg of CO2 reduction per year.

World's first "Vacuum Chilled equipped Refrigerator". No.1 energy-saving performance among household refrigerators in Japan!

The Agency for Natural Resources and Energy of the Ministry of Economy, Trade and Industry announced the FY 2007 (the 18th ) Energy Conservation Grand Prize in January 2008. Hitachi Appliances, Inc. won two Energy Conservation Center Chairman's Awards for household freezer-refrigerator 「Nutritious and fresh Vacuum Chilled」 and 「Center freezing」 series (R-X6000 and eight other models) as well as Room Air Conditioner 「Stainless Steel Clean Mr. White bear with mist」(RAS-S40X2 and all models). The refrigerators won awards for two consecutive years.

The refrigerators are awarded for No.1 energy-saving performance among home refrigerators in Japan, which is achieved by adopting a 「center freezing」 structure and the industry's first 「Flex Vacuum Insulation」.

As a result, compared to the refrigerator of the previous year, energy consumption reduced by about 20% and CO2 emissions reduced by approximately 49 kg. There was a remarkable improvement.

World's Best Vacuum Technology that was listed in the Guinness Book of Records

Last September, when announcing new Hitachi refrigerators for the Fiscal year 2007, Hitachi Appliances, Inc. (President Naosumi Ishizu) emphasized that Hitachi succeeded in incorporating 「The world's first vacuum chilled」 into Hitachi refrigerators, which prevent oxidation and retain nutrients through vacuum power. Executive Director of the Home Appliance Division Yoshitaro described Hitachi's refrigerators as "It is a premium product that meets the particular needs of consumers."

The combined vacuum technology of the Hitachi group made it possible to incorporate 「The world's first vacuum chilled」 into the new model refrigerators. The Hitachi Group has the vacuum technology of 1/1016 atm which was listed in the Guinness Book of Records. The world's first 「vacuum chilled room」 technology was developed through this world's best vacuum technology.

New product Hitachi Mannaka(Center) Refrigerator "Nutritious Vacuum Chilled" was developed using the 「vacuum chilled room」 technology, and this product focuses on health and basic performance. The adoption of a new vacuum insulation material made it possible to achieve both the industry's No.1 large capacity of 601 liters and energy conservation.

Equipped with food preservation technology and Large capacity refrigerator

According to a survey Hitachi conducted, the market for home refrigerators were about 4.28 million units in the fiscal year 2007, and about 4.32 million units in the fiscal year 2008. The composition ration of demand for the 500-liter class was 6% in the fiscal year 2006 but was expected to increase to more than 10% from 2007 and beyond. This may be due to a shift in replacement demand from the 400-liter class to higher capacity, which is attributed to improvements of installation of large-capacity refrigerators, higher room temperature in kitchens due to the increasing density of houses, and an increase of foods that need to be frozen and refrigerated.

On the other hand, due to the growing health consciousness in recent years, the retention of nutrients during food storage is required. To meet these needs, Hitachi developed a large-capacity refrigerator with food prevention technology under low-oxygen conditions to preserve as many nutrients as possible from oxidation.

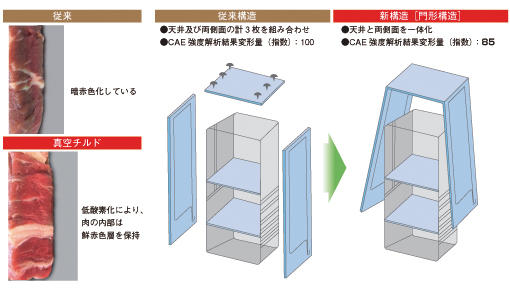

Figure 1. Structure of Vacuum Chilled Room and Opening and Closing Structure

Features of 601L「R-X6000」

The main features of the new product are introduced below using the 601-liter "R-X 6000" as an example. (1) World's first 「vacuum chilled room」 (Figure 1) retains nutrients in food. For the first time in the world, this product is equipped with a 「vacuum chilled room」 having a pressure-resistant sealing structure, a high-performance small vacuum pump, and a lock handle in the lower part of the refrigerator.

High-Performance small pump developed by Hitachi.

(Pumping capacity : 2.4 L/min. Rotation number: 2,100 r/min. Power consumption: 8 W)

The room is sealed with a lock handle, and the air in the chilled room is sucked by a high-performance small vacuum pump to lower the air pressure and allow food to be stored under low oxygen conditions. When the air pressure is reduced, the effect of preventing the oxidation is increased, but on the other hand, discoloration due to low oxygen occurs. The optimum pressure (vacuum) in the chilled room was determined to be about 0.7 atm to avoid oxidation and discoloration based on the result of many tests.

This protects the oxidation-sensitive nutrients in various foods, including DHA and EPA (both are essential fatty acids that must be taken from food and are found in fish), vitamin C(a water-soluble vitamin found in many vegetables and fruits), coenzyme Q10(coenzymes found in bluefish and meat), amino acids (methionine), vitamin A(a fat-soluble vitamin found in liver and green-yellow vegetables), and vitamin E(a fat-soluble vitamin that is abundant in leafy vegetables). (Figure 2)

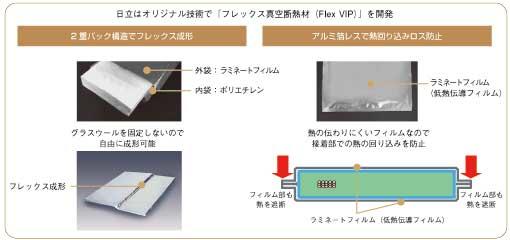

(2)In order to achieve the industry's largest inner capacity (601 L), in addition to the gate-shaped housing, we used 「flex vacuum insulation」 for the first time in the industry. (Figures 3 and 4)

Figure 2. Discoloration prevention Effect / Figure 3. Diagram of New structure

First, a gate-shaped structure, in which the side and top wall of the refrigerator were integrated to improve the strength of the entire housing by about 15% compared with the conventional refrigerator, was adopted. The gate-shaped structure allowed to reduce the thickness of the wall and make all the walls of the refrigerator thinner.

Also, the newly developed 「flex vacuum insulation」 (Figure. 4), which has improved insulation performance by approximately 25% compared to conventional products and is formed to be fit to the uneven shape inside the housing, was adopted for the first time in the industry. As a result, the vacuum insulation material can be used in the ceiling of the refrigerator where the vacuum insulation material could not be installed due to the level difference caused by the control board. The Increase in vacuum insulation area allowed to reduce the wall thickness and to save energy.

(3)Other features include the compact design and high-performance new compressors. Hitachi Appliances, Inc. planned to increase its production capacity for large refrigerators in the fiscal year 2008 and increase its production capacity by 20% from the previous year. Hitachi Appliances, Inc. also planned to invest a total of about 1 billion yen in facilities by the end of the fiscal year 2009 to support the further increases in production.

Figure 4. Hitachi's unique vacuum insulation technology

Easy Technical Explanation

Insulation

Vacuum insulation is a method to make it difficult to transfer heat to air or materials that have the property of transferring heat.

Oxidation Prevention.

It is necessary to block oxygen from anything that you don't want to oxidize to prevent oxidation.

When a sealed space is evacuated using a vacuum pump, oxygen in the area is removed by pumping it to the outside.

In a vacuum state, the amount of oxygen decreases, so it is possible to suppress changes of substances caused by oxidation.

If you want to know more about vacuum, please go to Vacuum Basics

Refrigerator Meets Vacuum Technology

Solution

- Big Science

- Lifestyle

- Technology

- Medical Field