Fundamentals of Vacuum Gauges

What is Multi Ionization Gauge?

Have you ever wished for such a great ionization vacuum gauge?

- The gauge head has to be stable.

- The gauge is available to measure vacuum in precise and stable.

ULVAC's multi ionization gauge G-TRAN Series ST2 lets you handle it in that way.

ST2 series is the only compact metal-tube triode-type indication vacuum gage. It is less replacement of the gauge head and more durable under harsh environments than B-A or cold-cathode types.

Table of Contents

Vacuum Equipment Trend

Did you know why vacuum gauges measuring inside of vacuum chambers get an error? Because the environment inside of the camber is harsh as follows. Organic substances adhere to the internal electrode of the gauge head, and the flow of electrons and ions is impaired.

- Outgassing released from ITO films and acrylic substrates for OLEDs and touch panels

- Outgassing released from cutting oil and cleaning liquid residues during processing vacuum chambers

- Outgassing released from wirings and motors in vacuum chambers

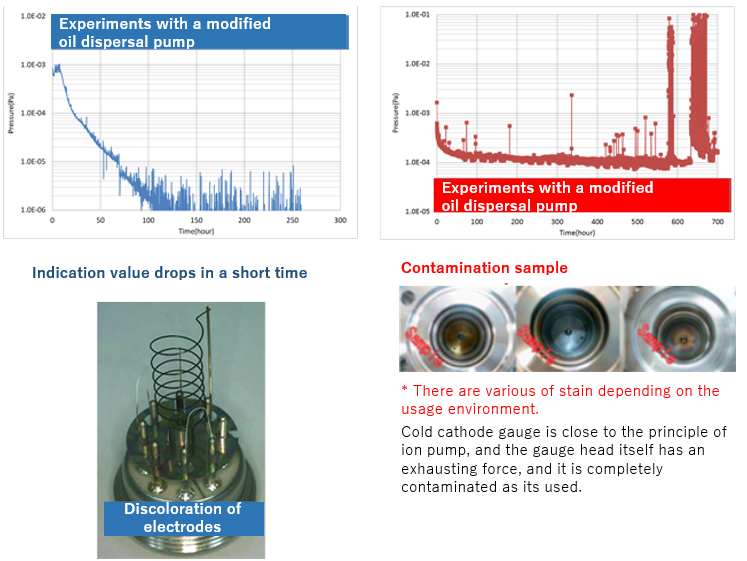

Oil Exposure Test Summary: B-A type and Cold-Cathode type

[B-A type ionization vacuum gauge Oil exposure test] [Cold-cathode type ionization vacuum gauge Oil exposure test]

| Type | B-A type ionization vacuum gauge | Cold-cathode type ionization vacuum gauge |

|---|---|---|

| Contamination test result | ・Sensitivity decreases in one day | ・There is a sudden big fluctuation, and it always fluctuates in around 25 days ・The sensitivity variation is large |

| Cause | ・Contamination of the ion collector ・Reduction of ion collection efficiency |

・Abnormal discharge due to deposit ・Reduced discharge due to contamination inside the sensor |

| Requirement | ・Improvement of contamination resistance ・Maintain accuracy of ±15% ・Small size, metal body |

・Improvement of contamination resistance ・There is a large error inaccuracy, so the improvement |

ST2 Series

ULVAC developed and commercialized a triode-type ionization vacuum gauge with high measurement accuracy (Variations in sensitivity, errors) and long life for vacuum measurement under high vacuum. This dramatically reduces running costs and improves yield.

1. Advantages of the triode-type structure

Stable sensitivity and high accuracy

- Reducing downtime due to vacuum gauges replacement and running cost

- Accurate pressure control

- It is possible to see differences between equipment.

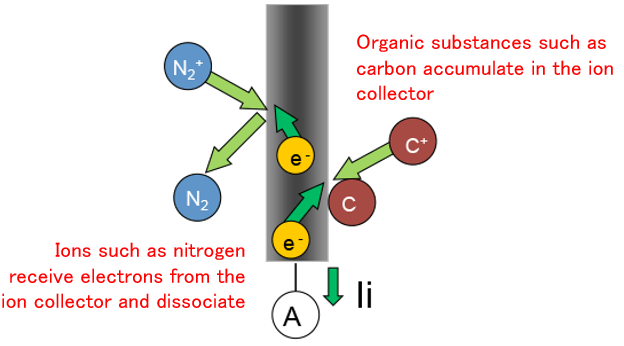

Mechanism of sensitivity deterioration.

B-A type ionization vacuum gauge VS Triode-type ionization vacuum gauge

| B-A type | Triode-type | |

|---|---|---|

| Sensitivity(1/Pa) | 0.06 | 0.07 |

| Area of an ion collector(mm2) | 0.15 | 2800 |

Since the sensitivity is almost the same, when the ion current value of both types is 1 × 10-7 A at 1 × 10-3 Pa, the ion current value per unit area of ion collector is as follows.

| B-A type | Triode-type | |

|---|---|---|

| Ion current value per unit area(A/mm2) | 6.7×10-7 | 3.6×10-11 |

When the ion current value per unit area is large, the number of ionized gas molecules collide with the ion collector is large.

B-A type is less affected by soft X-rays and has a high ion collection efficiency in measuring a low pressure. However, because of its high ion collection efficiency, the deposition amount of organic substances is larger than that of the triode-type.

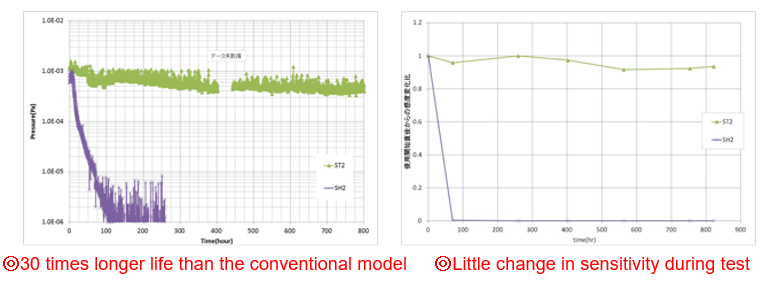

Oil exposure test with ST2

![]()

![]()

【Test using a modified oil diffusion pump】 【The ratio of sensitivity variation after the start of use】

| Type | Multi ionization gauge ST2 | B-A type ionization vacuum gauge | Cold-cathode type ionization vacuum gauge |

|---|---|---|---|

| Pressure indication stability | Normal for more than 30 days | Stability of pressure indication decreases in one day | There is a sudden big fluctuation It always fluctuates in around 25 days |

| Sensitivity stability | No change for more than 30 days | Sensitivity decreases in one day | More than 50% variation |

- Reduce downtime of the equipment and running costs

- Always accurate pressure control

- Understanding differences between devices

2. Ir/Y2O3filament

Since ST2 has a longer life, it reduces downtime due to vacuum gauges replacement and running costs.

3. Compact metal tube

It reduces install space and has a lower risk of gauge head damage

- Since the internal volume is about 1/7 and the length is about 1/3 compared with the conventional glass tube type, ST2 reduces the installation space.

- Compared to conventional glass tubes, there is a lower risk of gauge head damage.

4. Multi-ion gauge type sensor unit

Control signals can reduce control signals by connecting the Pirani vacuum gauge unit.

- Connecting the optional Pirani vacuum gauge unit SPU enables automatic filament control.

- Indicated values can be output as a single signal from the Pirani vacuum gauge to the ionization vacuum gauge.

- Existing ISG1 can be used.

Fundamentals of Vacuum Gauges

HOW TO

- Vacuum Tech Basics

- Fundamentals of Vacuum Pumps (Low to Medium Vacuum)

- Fundamentals of Vacuum Pumps (High Vacuum)

- Fundamentals of Vacuum Valves

- Fundamentals of Vacuum Gauges

- Fundamentals of Quartz Crystal Oscillation Type Deposition Controller

- Fundamentals of Leak Detection

- Fundamentals of High-Speed Spectroscopic Ellipsometer

- Fundamentals of Gas Analyzer (Process Gas Monitor)

- The Others

- How to Choose The Best Products

- Old Models vs. New Models

- Troubleshooting