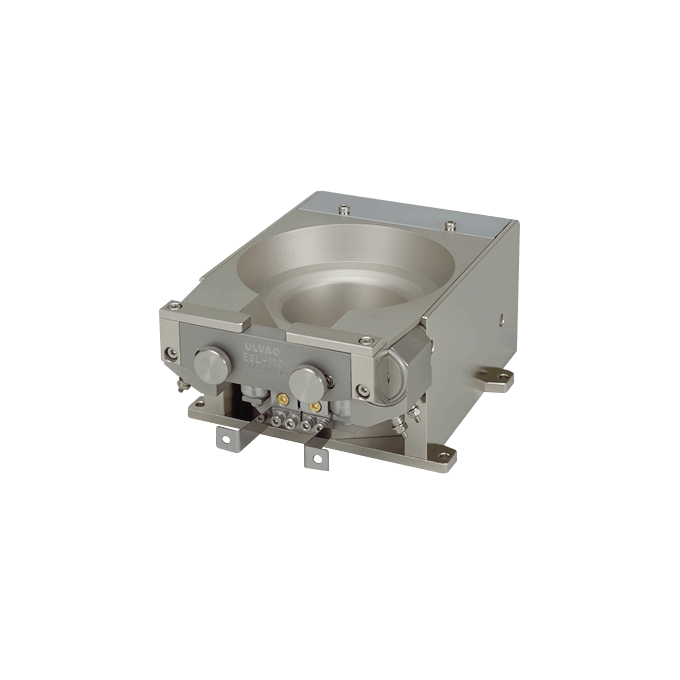

EB Source for Metal Film

EGL Series

EGL-110

ULVAC

EGL-110 electron beam evaporation source is designed to improve performance and reliability based on ULVAC's many years of technical experience and achievements.

This evaporation source has a hearth with a maximum input power of 16kW.

The crucible has a large capacity of 110 cc, which enables the high-speed deposition of thick films.

This evaporation source has a hearth with a maximum input power of 16kW.

The crucible has a large capacity of 110 cc, which enables the high-speed deposition of thick films.

Features

- Large-capacity vapor deposition is possible by adopting a large capacity 110cc hearth.

- The electron beam is deflected by the electromagnetic field, the effect of secondary electrons on the deposition target is extremely small.

- By scanning the beam spot in the X-axis and Y-axis directions even with a sublimable substance, the partial digging phenomenon can be eliminated and the entire crucible can be evaporated smoothly. (Japan patent 831485, 843447)

- The electron beam is deflected 270°, so it is not exposed to the above from the vaporized material and the filament has a long life.

- Since the emitter assembly can be easily attached and detached, it is easy to replace the filament, insulator, etc.

Specifications

| Acceleration voltage | -4kV~-10kV | |

| Beam current | 1.6Amax (at-10kV) | |

| Maximum input | 16kW (-10kV, 1.6A) | |

| X-axis deflection coil | 0.4~3.5A -18VDCmax 2.8Ω(20℃) |

|

| Y-axis deflection coil | 0~±1.2A ±12VDCmax 0.9Ω(20℃)2 pcs |

|

| Filament | 0~6VAC 40Amax | |

| Crucible | Volume | 110cc |

| Size | 75Φ×59Φ×32H | |

| Beam deflection angle | 270° | |

| Effective evaporation angle | 120° or more | |

| Deposition rate | Al at 16kW | 4.5μm/min or more (At 250H directly above Hearth) |

| Cooling water amount | 19L/min or more, 0.7MPa(maximum pressure) | |

| Water temperature | 15℃~25℃ | |

| External dimensions | 136W×90H×220D | |

| Weight | About 15kg | |

| Applicable power supply | HPS-1000N, HPS-1600F | |

| Remarks | 1. Able to attached wire feeder. 2. Cooling water with a specific resistance of 5 kΩ?cm or higher is recommended. |

|