Vacuum Pumping System Model: YMV

ULVAC

For more information on ULVAC products, purchase, and/or consideration, click here.

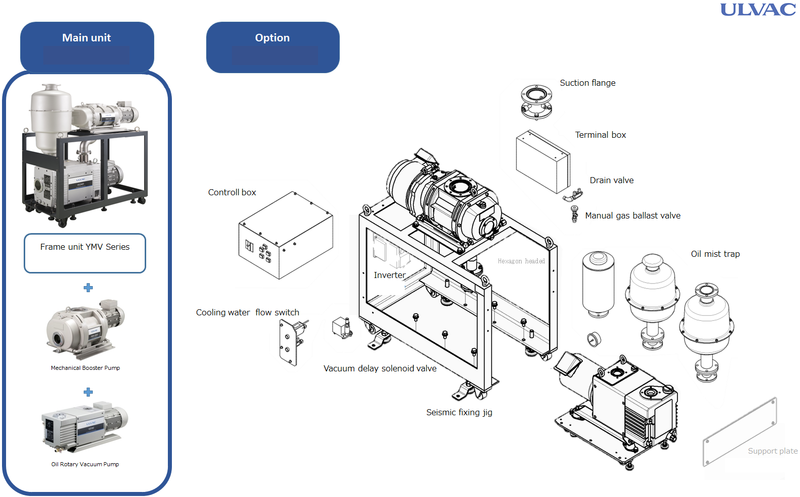

4 types of frame units in accordance with the pump exhaust amount have prepared.

It has an independent frame design that emphasizes the pump maintainability, making ideal for production usage.

Note: Mechanical booster pump and oil rotary vacuum pump needs to be purchased separately.

Features

- Extensive lineup

To allow Pump Selection tailored to emissions, we prepared four kinds of cradle unit. - Excellent maintainability

Since the frame unit for mechanical booster pump / oil rotary vacuum pump is independent, removement of main piping on the device side is not necessary at the timing of oil rotary vacuum pump maintenance and customer friendly. - Abundant options

Oil mist trap, atmospheric pressure drive type (inverter), control panel, delayed vacuum solenoid valve, cooling water flow switch, etc. can be selected.

Specifications

| Frame Unit *1 | YMV-01A | YMV-03A | YMV-06A | YMV-12A | ||||||

| Bellows, Caster with adjuster | Bellows, Caster with adjuster | |||||||||

| Recommended pump *2 |

Mechanical booster pump |

PMB 100D |

PMB 300D |

PMB 600D |

PMB 600D |

PMB 1200D |

||||

| Oil rotary pump |

VD30 | VD40 | VD60 | VD90 | VS1501 | VS2401 | VS1501 | VS2401 | ||

| Maximum pumping speed |

50Hz | 95 m3/h (1,580 L/min) |

250 m3/h (4,100 L/min) |

450 m3/h (7,500 L/min) |

500 m3/h (8,330 L/min) |

550 m3/h (9,200 L/min) |

600 m3/h (10,000 L/min) |

850 m3/h (14,200 L/min) |

1,000 m3/h (16,700 L/min) |

|

| 60Hz | 115 m3/h (1,900 L/min) |

290 m3/h (4,800 L/min) |

520 m3/h (8,670 L/min) |

600 m3/h (10,000 L/min) |

660 m3/h (11,000 L/min) |

720 m3/h (12,000 L/min) |

1,000 m3/h (16,700 L/min) |

1,200 m3/h (20,000 L/min) |

||

| Max. Suction pressure |

50Hz | 8.5 X 103 Pa |

7.0 X 102 Pa |

1.0 X 103 Pa |

1.3 X 103 Pa |

1.5 X 103 Pa |

2.4 X 103 Pa |

1.3 X 103 Pa |

1.7 X 103 Pa |

|

| 60Hz | 4.5 X 103 Pa |

7.0 X 102 Pa |

1.0 X 103 Pa |

1.1 X 103 Pa |

1.3 X 103 Pa |

2.1 X 103 Pa |

1.1 X 103 Pa |

1.7 X 103 Pa |

||

| Ultimate pressure *3 |

4.0 X 10-1 Pa | 6.7 X 10-1 Pa | ||||||||

| Cooling method *4 |

Air cooled |

Air cooled / Water cooled | Water cooled | |||||||

| Cooling water |

Primary side pressure |

- | 0.3 Mpa | 0.3 Mpa | ||||||

| Inlet / outlet differential pressure volume |

- | 0.05 Mpa | 0.1 Mpa | |||||||

| Cooling water capacity |

- | 2.0 ≦ L/min | 4.0≦ L/min |

5.0≦ L/min |

4.0≦ L/min |

5.0≦ L/min |

||||

| Cooling water temperature |

- | 5 - 30 ℃ | 5 - 30 ℃ | |||||||

| Inlet port JIS-B-2290 |

VG50 equivalent ( KF50 or ISO63F (optional) |

VG80 equivalent ( ISO80F or 100F optional ) |

VG80 equivalent ( ISO80F or 100F optional ) |

VG100 equivalent ( ISO100F optional) |

||||||

| Outlet port JIS-B-2290 |

VG40 equivalent ( KF40 optional ) | VG50 equivalent ( KF50 or ISO63F optional ) |

||||||||

| Dimension W X D X H |

500 X 860 X 848 mm |

500 X 860 X 920 mm |

500 X 960 X 1030 mm |

500 X 960 X 1030 mm |

650 X 1200 X 1238 mm |

650 X 1200 X 1238 mm |

650 X 1200 X 1258 mm |

650 X 1200 X 1258 mm |

||

| Weight ( including the recommended pump weight ) |

145 kg | 175 kg | 260 kg | 285 kg | 480 kg | 520 kg | 530 kg | 570 kg | ||

| Option | Atmospheric operation |

For PMB 100D I2 |

For PMB 300D I2 |

For PMB 600D I2 |

For PMB 600D I2 |

For PMB 1200D I2 |

||||

| For PMB 100D I4 |

For PMB 600D I4 |

For PMB 600D I4 |

For PMB 1200D I4 |

For PMB 1200D I4 |

||||||

| Oil mist trap | TM201 / TM401 | TM401 / TM-2 (F) | TM-3 (F) | TM-4 (F) | TM-3 (F) | TM-4 (F) | ||||

| Control box *6 |

For PMB 100D + VD30 |

For PMB 300D + VD40 |

For PMB 600D + VD60 |

For PMB 100D + VD90 |

For PMB 600D + VS1501 |

For PMB 600D + VS2401 |

For PMB 1200D + VS1501 |

For PMB 1200D + VS2401 |

||

| Terminal box | For PMB 100D + VD30 |

FOr PMB 300D + VD40 |

For PMB 600D + VD60 |

FOr PMB 100D + VD90 |

For PMB300D/ PMB600D |

For PMB1200D | ||||

| Suction flange *7 | For PMB100D |

For PMB300D/ PMB600D |

For PMB300D/ PMB600D |

For PMB1200D | ||||||

| Vacuum delay solenoid valve *8 |

Common (select from DC24V, AC200V, AC220V,AC380V, AC400V, AC415V or AC440V) |

Common (select from DC24V, AC200V, AC220V,AC380V, AC400V, AC415V or AC440V) |

||||||||

| Cooling water flow switch *9 |

- | For PMB300D + VD40/PMB600D + VD60/PMB600D + VD90 |

For PMB600D + VS1501 |

For PMB600D + VS2401 |

For PMB 1200D + VS1501 |

For PMB 1200D + VS2401 |

||||

Note)“Model:YMV” is the frame unit for mechanical booster pumps. Purchase the mechanical booster pump and oil rotary pump separately.

Refer to the brochure about the specification of mechanical booster pumps and oil rotary pumps. Options for individual pump are available. ( Select the inverter for atmospheric pressure start operation from options for Model:YMV ).

*2 Combination with recommended pumps.

*3 Ultimate pressure is measured by Pirani vacuum gauge.

*4 Water cooled operation is required depending on intake pressure.

Refer to the brochure of the mechanical booster pump for details.

*5 Select the inverter from I2 or I4. I2 is for 200 to 240V and I4 is for 380V to 480V.

*6 Select the control box from AC200V, AC220V, AC380V, AC400V, AC415V, AC440V, AC460V or AC480V.

*7 Suction flange includes Φ 18 gauge port, leak port and 1/4B socket.

*8 1/4B socket is necessary to connect the delay vacuum solenoid valve.

Optional suction flange is recommended.

*9 DC24V cooling water flow switch.