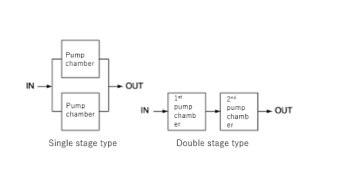

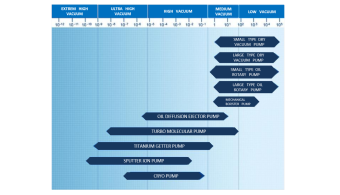

Multi-Stage Roots Type Dry Vacuum Pump

HR/UR Series

HR

アルバック

Uniformity of high temperature distribution. It is possible to exhaust the sublimates generated by CVD and etching processes in a gaseous state.

Features

- Uniform high temparature distribution pump

The HR series pump is designed to keep uniform high temparature for applications that require a heated pump, heated gas lines, and/or heated exhaust lines

The UR series pump is enable to keep higher temparature than HR series. - Excellent helium pumping capability

Canned motor for safety and ease of maintenance - Power failure protection

Pump withstands power interruptions of up to 1000ms duration. - Superior resistance for corrosive gas:

Internal components are specially treated providing a high degree of surface hardness and corrosion resistance. This prevents wear and corrosion of internal pump parts when exposed to corrosive gasses. - Communication function:

Pump data including warnings and alarms are able to be exported. Extensive pump control is available.

Applications

- CVD equipment

- Etching equipment

- Ashing equipment

- ALD、ALH etc

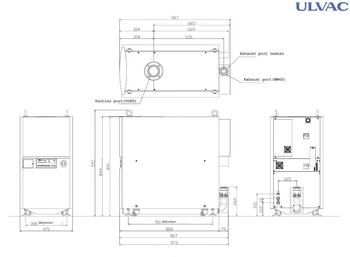

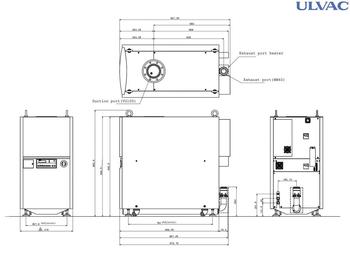

Specifications

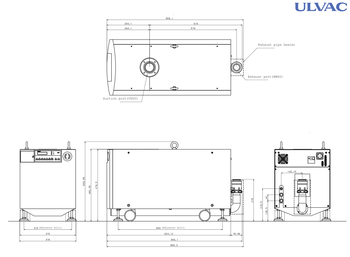

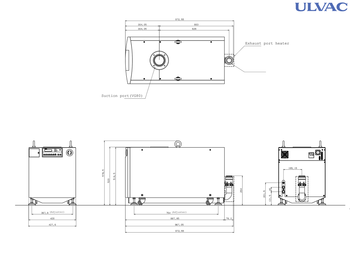

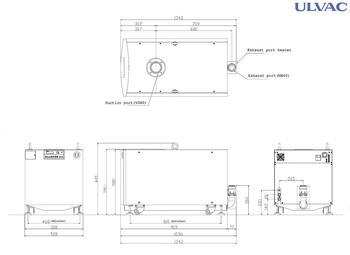

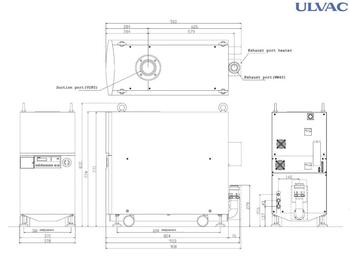

| Model | HR60 | HR90 | HR300 | HR600 | HR1200 | ||

| Pump | DRP | HR60 | HR90 | HR60 | HR90 | HR90 | |

| MBP | - | - | PRC-003A | PRC-006A | PRC-012A | ||

| Max. pumping speed |

50Hz | m3/h (L/min) |

62(1030) | 112(1860) | 359(5,980) | 653(10,900) | 1,012(16,900) |

| 60Hz | m3/h (L/min) |

80(1333) | 126(2100) | 365(6,080) | 701(11,700) | 1,051(17,500) | |

| Ultimate pressure | Pa | 5 | 0.67 | ||||

| Max. inlet pressure | Atmospheric pressure *1 | ||||||

| Max. exhaust pressure | Pa | 1.0 to Atmospheric pressure | |||||

| Inlet diameter (type CE) | VG50(KF50) | VG80(KF50) | VG80(KF80) | VG100(KF100) | |||

| Outlet diameter | KF40 | ||||||

| Weight | kg | 180 | 245 | 275 | 370 | 420 | |

| Power | Three phase |

VAC (Hz) |

200(50/60), 220(60) | ||||

| Current | At ultimate pressure |

A | 7.1 (at 200V) |

11.2 (at 200V) |

7.8 (at 200V) |

12.9 (at 200V) |

15.4 (at 200V) |

| At max. load |

A | 7.3 (at 200V) |

11.8 (at 200V) |

8.1 (at 200V) |

13.8 (at 200V) |

18.9 (at 200V) |

|

| Cooling water Supply pressure |

MPa | 0.1~0.3 | 0.1~0.3 | ||||

| Cooling water In/Out differrencepressure |

MPa | >0.1 | |||||

| Cooling water Flow rate | L/min | >5.0 | |||||

| N2 gas | Supply pressure |

MPa | 0.1~0.5 | ||||

| Regula- ted pressure |

MPa | 0.05~0.1 | |||||

| N2 purge | Shaft purge |

SLM | 5 | ||||

| Gas ballast | SLM | 0~45 | |||||

*1 HR300, HR600 and HR1200 should all be operated below 200Pa (1.5 Torr).