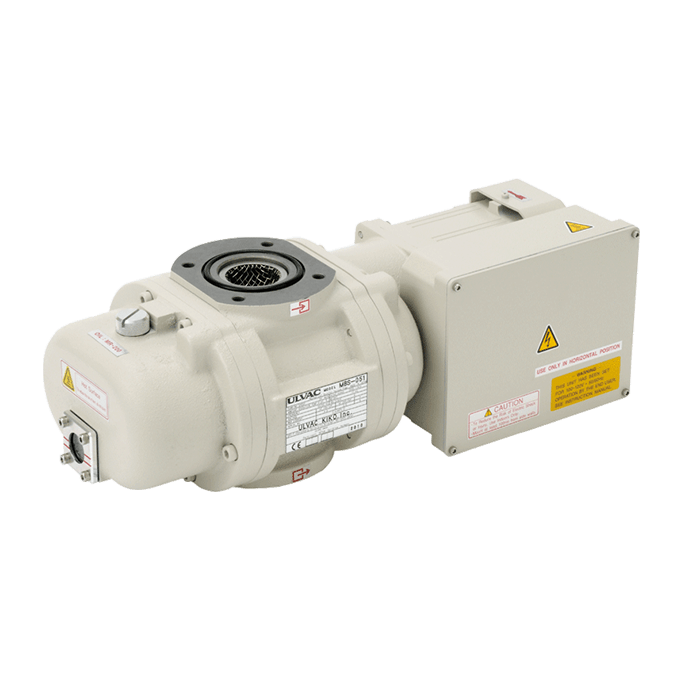

Mechanical Booster Pump Model: MBS-053

ULVAC

For more information on ULVAC products, purchase, and/or consideration, click here.

Features

Small type of roots type vacuum pump.

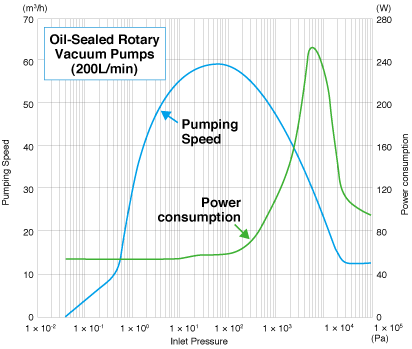

In the pressure area where the pumping speed of Sub pump decreases, the pumping speed can be greatly increased.

- By adopting a DC brushless motor, it can be operated at an optimum rotational speed according to the load, so vacuum exhaust from atmospheric pressure is possible.

- No oil leakage to the outside of the pump due to the magnetic coupling structure.

- The pump's internal seal uses a non-contact seal, which significantly reduces mechanical loss.

(Power consumption is reduced by about 60% compared to the old model) - It is possible to operate with 100V system and 200V system by switching power supply inside the driver box.

Specification

| Unit | Specifications | |

| Actual Pumping Speed ※1 | m3/h | 50 |

| Ultimate pressure ※2 | Pa | 4.0×10-2 |

| Motor | DC brushless motor, 200W | |

| Power supply※3 | AC Single phase 100-120V / 200-240V (50/60Hz) | |

| Nominal speed | r/min | 3500 |

| Current | A | 1.2 (AC 100V) / 0.8 (AC 200V) ;Ultimate pressure |

| 4.33 (AC 100V) / 2.54 (AC 200V) ;Full load | ||

| Power consumption | W | 50 ;Ultimate pressure |

| 250 ;Full load | ||

| Oil capacity | mL | 70 |

| Recommended oil | SMR-200 | |

| Weight | kg | 11 |

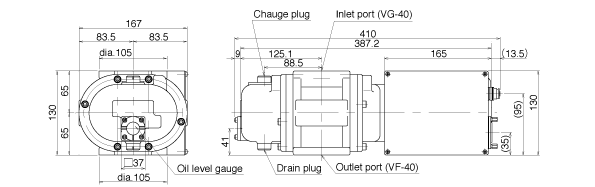

| Inlet flange | JIS VG-40 | |

| Outlet flange | JIS VF-40 | |

| Backing pump | Oil Rotary pump 130~240L/min | |

| Ambient temperature | ℃ | 0~40 |

| External dimensions | mm | 167(W)×410(L)×130(H) |

※2:Measured by ionization vacuum gauge. Ultimate pressure varies depends on ultimate pressure of backing pump.

※3:Power supply plug and Power supply code are not included.

Corresponding certificate/Voltage

| Model | Applicable standard※ | CE Declartion of confirmity |

1Φ 100~120V |

1Φ 200~240V |

3Φ 200~240V |

3Φ 380~460V |

| MBS-053 | TUV | ● | ● | ● | - | - |

✓:Standard、○:Option、-:Not Applicable

※TUV Certification: A high-quality product that complies with European standards as assessed by an international third party that conducts product safety testing and certification.

Caution

|

1

|

Cannot use mechanical booster vacuum pump with a unit, and combine it with a backing vacuum pump (Fore Pump) by all means.

|

|

2

|

Mechanical Booster Pump becomes design to use in an inline.

Fix flange of the outlet side, and install a pump in this flange. |

|

3

|

Since pump oil bubbles at the time of starting when not operating initial operation and for a long period of time, please perform the exhaust gas for degassing with a backing vacuum pump.

|

|

4

|

Since operation in the atmospheric pressure neighborhood becomes the same grade as the exhaust speed of a backing vacuum pump, the feature of a booster is not demonstrated.

|

|

5

|

If pump oil exceeds the amount of regulations, oil will go into a rotor indoor part.

|

|

6

|

Please be sure to check that power supply voltage has agreed with the setting voltage of a pump.

|

|

7

|

The base for pump installations is not equipped. It becomes flange fixation.

|

|

8

|

The handle for pump carrying is not equipped.

|

|

9

|

Power cable and Unplug-preventive hardware is optional parts.

|

Dimension drawing

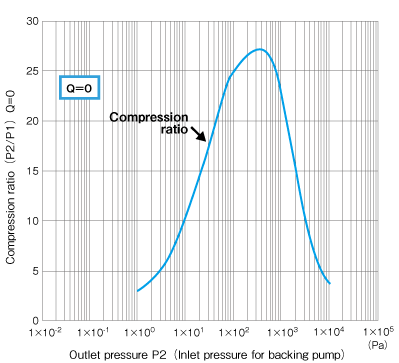

Compression ratio

Pumping Speed Curves(ex)

Optional parts

|

Item

|

Model

|

Remarks

|

|

Power cable

|

With 100-120V plug

|

Unplug preventive hardware

|

|

Power cable

|

100-120V without plug

|

Unplug preventive hardware

|

|

Power cable

|

200-240V with plug

|

Unplug preventive hardware

|

|

Power cable

|

200-240V without plug

|

Unplug preventive hardware

|

|

Unplug preventive hardware

|

100-120V

|

Single item

|

|

Unplug preventive hardware

|

200-240V

|

Single item

|

|

Electric voltage change connector

|

100-120V (Red)

|

for 100V range, standard accessories ※

|

|

Electric voltage change connector

|

200-240V (Blue)

|

for 200V range, standard accessories ※

|

|

Vacuum pump oil

|

SMR-200

|

70mL, standard accessories

|