Lifestyle

#03 Classification of Leak Detection Methods

ULVAC Group is a unique corporate group that provides a wide range of comprehensive vacuum technologies, including vacuum systems, vacuum equipment, materials, analytical equipment, and customer solutions, for various industries.

However, you might wonder, "What is the wide range of vacuum technologies?" or "Where in various industries is the vacuum technology used? "

You might be surprised to know that vacuum technology hides in various places around us.

Did you know that vacuum technology is also used in home air-conditioner (Ductless Mini-Split System Air Conditioners), essential to our daily lives throughout the year?

15 Ways to Check for Refrigerant Leaks

As mentioned in the previous article, manufacturers perform leak tests when manufacturing air conditioners, and installers also conduct leak tests when installing them. What kinds of leak tests are there? JIS (Japanese Industrial Standards) classifies leak tests as follows:

Table of Contents

Leak Test by using Fluorescent dye

Leak Test by using Developer

Leak Test by using Penetrant

Leak Test by using Gas such as Air

Bubble Test

Foam Leak Test

Pressure Decay Leak Test

Flow Rate Leak Test

Ultrasonic Leak Test

Vacuum method

Hood method

Spray method

Pressurization method

Sniffer method

Suction cup method

Bell jar method

Pressure accumulation method

Bombing method

Leak Test by using Liquid

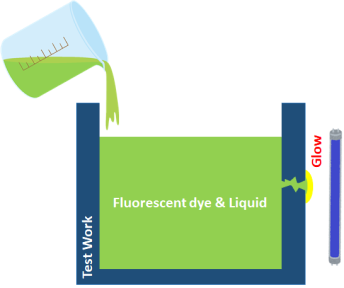

- Leak Test by using Fluorescent dye

An operator fills the test work with a liquid containing a fluorescent dye and irradiates the outside of the test work with UV light. If there is a leak, the fluorescent dye escapes from the inside of the test work to the outside. The leaked fluorescent glows by the UV light, enabling to spot the leakage visually.

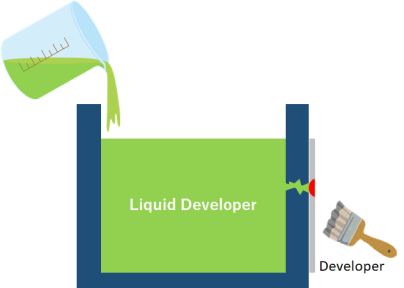

- Leak Test by using Developer

An operator fills the test work with a liquid and applies a developer, which reacts with the liquid and develops color, on the area to be tested outside the test work. If there is a leak, the liquid leaks to the outside of the test work due to the capillary phenomenon and reacts with the developer to change the color of the leaking location.

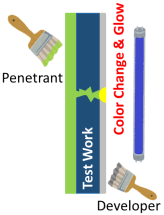

- Leak Test by using Penetrant

An operator applies a penetrant on one side of the test work, and a developer, which reacts with the penetrant to develop color, on the other side of the test work. If there is a leak on the developer applied side, the penetrant is drawn out to the developer applied side due to the capillary phenomenon. The drawn-out penetrant reacts with the developer to develop and change the color.

The leak tests using liquid have the advantage of easy to inspect, but they also have the disadvantage of having to clean the liquid used after the leak test. Also, tiny leaks may not be detectable.

Leak Test by using Gas such as Air

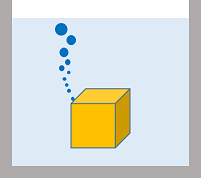

- Bubble Test

An operator pressurizes the inside of the test work with a gas such as air and immerses it in a liquid such as water. Then the operator determines the leakage by checking bubbles from the test work visually.

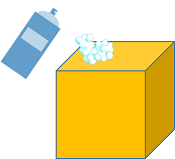

- Foam Leak Test

An operator pressurizes the inside of the test work with a gas such as air and applies a foaming liquid such as a surfactant on the test work. If foam develops, it indicates there is a leak.

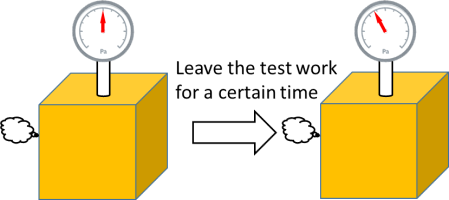

- Pressure Decay Leak Test

An operator pressurizes or depressurizes the inside of the test work with a gas such as air and leave it for a certain time. The operator determines the leakage by the pressure difference inside the test work before and after the test.

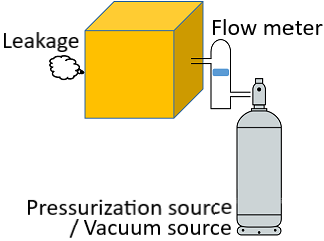

- Flow Rate Leak Test

An operator pressurizes or depressurizes the inside of the test work with a gas such as air to reach certain pressure. The operator determines the leakage by the value of the flow meter between the pressurization source or depressurization source and the test work.

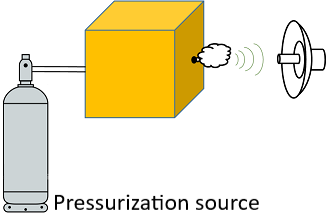

- Ultrasonic Leak Test

This method detects the ultrasonic waves generated when gas leaks from the leaking location of the test work.

Leak tests using gas have advantages and disadvantages. They vary depending on conditions, such as the amount of capital investment, the amount of detectable leakage, post-processing or not, the misjudgment of leakage, and the leaking location identification.

Leak Test by using Search Gas

This method uses a specific gas as a search gas to pressurize or depressurize the inside of the test work. An operator performs the leak test using an analyzer that can detect the gas with high sensitivity. Helium, hydrogen, halogen gas, and ammonia gas are mainly used as search gas. There are two methods for leak tests using search gas: the vacuum method, which vacuum the inside of the test work to check the leakage, and the pressurization method, which pressurizes the inside of the test work to check the leakage. Please refer to Episode 4 for the details of the vacuum method and the pressurization method.

Comparison of Leak Test Methods

As described above, there are nine major leak test methods, each with its own features, advantages, and disadvantages. The following table compares these leak test methods:

| Leak Test by using Liquid | Leak Test by using Gas | Leak Test by using Search Gas |

|||||||

| Leak Test by using Fluorescent dye | Leak Test by using Developer | Leak Test by using Penetrant | Bubble Test | Foam Leak Test |

Pressure Decay Leak Test | Flow Rate Leak Test |

Ultrasonic Leak Test |

||

| Identification of Leak Location | Yes | Yes | Yes | Yes | Yes | No | No | Yes | Depending on methods |

| Pressurize/ Depressurize the Test work | Pressurize | Pressurize | - | Pressurize | Pressurize | Pressurize Depressurize |

Pressurize Depressurize |

Pressurize | Pressurize Depressurize |

| Cleaning | required | required | required | Drying required | required | not required | not required | not required | not required |

| Detectable Leak amount [Pa・m3/sec] |

10-3 | 10-3 | 10-3 | 10-3 | 10-5 | 10-5 | 10-5 | 10-3 | 10-7 |

| Object Fluid | Water・Oil | Water・Oil | Penetrant | Air | Air | Air | Air | Air | Helium, Hydrogen, Halogen gas, Ammonia gas |

The Leak test by using search gas can detect the leakage more sensitively than other methods. In the next article, we will explain the leak test by using search gas in detail.

Lifestyle

-

Protect nutrients by preventing oxidation with a vacuum chilled

-

#05 Helium Leak Detector

-

#04 Gas Leak Detection Methods

-

#03 Classification of Leak Detection Methods

-

Built-in small diaphragm pump for tasty and long-hour storage

-

#02 The Importance of Refrigerant Leak Detection

-

#01 How The Air Conditioner Works

Solution

- Big Science

- Lifestyle

- Technology

- Medical Field