Lifestyle

#04 Gas Leak Detection Methods

ULVAC Group is a unique corporate group that provides a wide range of comprehensive vacuum technologies, including vacuum systems, vacuum equipment, materials, analytical equipment, and customer solutions, for various industries.

However, you might wonder, "What is the wide range of vacuum technologies?" or "Where in various industries is the vacuum technology used? "

You might be surprised to know that vacuum technology hides in various places around us.

Did you know that vacuum technology is also used in home air-conditioner (Ductless Mini-Split System Air Conditioners), essential to our daily lives throughout the year?

Gas Leak Detection

In the previous article, we introduced various leak test methods. We also explained that the leak test using search gas detects the leakage more sensitively than other leak test methods using liquid or gas.

In this article, we will take a closer look at the leak test by using search gas. Let's find out why this test method detects the leak highly sensitively.

Table of Contents

Helium gas

Hydrogen gas

Halogen gas

Ammonia gas

Helium Leak Test

Hydrogen Leak Test

Halogen Leak Test

Ammonia Leak Test

(1) Vacuum method (The method that the search gas flows into the inside of the test work.)

(2) Pressurization method (The method that the search gas flows out from the inside of the test work.)

(3) Bombing method (The method that the search gas flows into and out from the test work.)

What are the Characteristics of Search Gas?

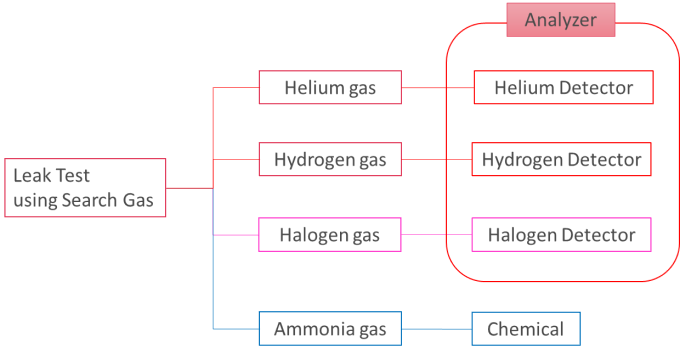

Search gas is a specific gas that can detect leaks easily and accurately. Four types of gases are used as a search gas: helium gas, hydrogen gas, halogen gas, and ammonia gas.

The characteristics of the four gases are as follows:

- Helium Gas

Since helium gas is an inert gas that is non-toxic and non-flammable, it can be used safely in various sites, environments, and products. Because of its small molecular size, it is excellent for detecting small leaks. However, helium gas is expensive. - Hydrogen gas

Because of the risk of explosion, hydrogen gas should be mixed with nitrogen gas or other gases and diluted to a non-flammable concentration (about 5% hydrogen gas) for safety reasons. - Halogen gas

Halogen gas contains halogen elements such as chlorine and fluorine. Many of them cause ozone layer depletion when released into the atmosphere. Due to the toxicity and impact on global warming, halogen gas must be handled with care. - Ammonia gas

Ammonia gas is used as a nitrogen gas mixture because of the risk of explosion at high concentrations. It has a strong pungent odor and is highly toxic, so it must be handled with great care.

Which Search Gas to Use? Leak Test Methods

The leak test by using search gas is a method to detect the leakage by using four specific gases and an analyzer (leak detector) that detect the leaks with high sensitivity or a chemical (test agent).

The four main test methods are as follows:

- Helium Leak Test

The helium leak test uses helium gas as a search gas. The device used to detect the helium gas is a helium leak detector. The helium leak detector uses the magnetic deflection mass spectrometer principle and is adjusted to detect only helium gas with high sensitivity. - Hydrogen Leak Test

The hydrogen leak test uses hydrogen gas as a search gas. Like the helium leak detector, the hydrogen leak detector uses the magnetic deflection mass spectrometer principle to detect. - Halogen Leak Test

The halogen leak test uses halogen gas as a search gas and a halogen leak detector (refrigerant detector) to detect the leakage. There are three types of halogen detectors: infrared absorption sensor type, heat semiconductor sensor type, and corona discharge type.

The infrared absorption sensor type detects the leakage amount by utilizing the property of halogen gas, which absorbs infrared rays of specific wavelengths. When refrigerant comes into contact with a heated sensor (filament), the electrical resistance changes. The heat semiconductor sensor type converts the change in electrical resistance into the leakage amount. The corona discharge type generates the corona discharge in the sensor, and when the refrigerant enters the sensor, the corona discharge disappears. This is how the corona discharge type detects the leakage.

Since halogen gas (refrigerant) destroys the ozone layer, the halogen leak test is conducted to inspect refrigerant leakage after the outdoor unit is filled with refrigerant. - Ammonia Leak Test

The ammonia leak test uses ammonia gas as a search gas. The test agent, which changes color (e.g., from yellow to blue) due to a chemical reaction when exposed to the ammonia gas, is applied to the surface of the test work. This method detects leaks as an indication.

Different Leak Test Methods Depending on the Structure of the Test Work!?

For the leak test using search gas, besides test methods depending on gas types, there are various methods depending on the test work structure, and which method to apply is an important factor.

There are three types of leak test methods depending on the test work structure: vacuum method, pressurization method, and bombing method.

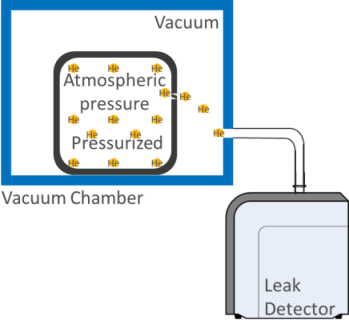

(1)Vacuum method (The method that the search gas flows into the inside of the test work)

In the vacuum method, the inside of the test work is evacuated first, and the outside of the test work is covered with a search gas. If there is a leak, search gas flows into the inside from the outside of the test work, and the detector detects the search gas that flows in. The main vacuum methods are as follows:

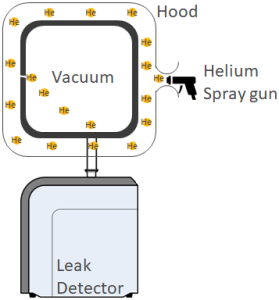

- Hood method

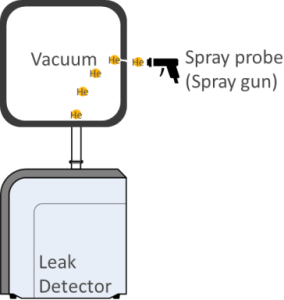

This method evacuates the inside of the test work and cover the part or the whole of the test work with the search gas and measure the search gas flowing into the inside of the test work to detect the leakage. - Spray method

This method evacuates the inside of the test work and sprays the search gas to the test work using a spray probe (spray gun) to detect the search gas that flows into the inside of the test work.

|

Hood method |

Spray method |

(2)Pressurization method (The method that the search gas flows out from the inside of the test work)

In the pressurization method, the search gas is supplied (filled) to the inside of the test work. If there is a leak, the search gas flows out of the test work. This method detects the outflowed search gas. The main pressurization methods are as follows:

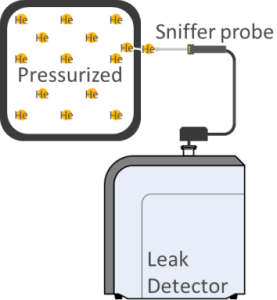

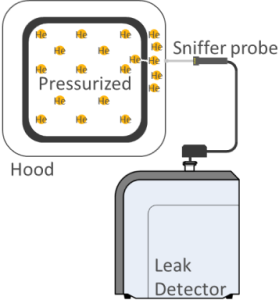

- Sniffer method

This method fills the test work with the search gas and draws in the search gas flowing out of the test work with a sniffer probe to detect the leak. - Suction cup method

This method fills the test work with the search gas and sucks in the search gas flowing out of the test work using a suction cup pressed against the test work to detect the leakage.

|

Sniffer method |

Suction cup method |

- Vacuum Chamber method (Bell jar method/ Chamber method)

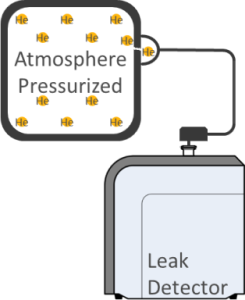

The test work filled with the search gas is placed in a vacuum chamber, and the chamber is evacuated. If there is a leak, the search gas will flow out of the test work. This method detects the outflowed search gas. - Pressure accumulation method

This method fills the inside of the test work with the search gas, covers the part or the whole of the test work with a hood, and keeps it in this state for a certain time. The search gas that flows out from the test work accumulates in the hood and is detected with a sniffer probe(spray gun).

|

Vacuum Chamber method (Bell jar method/ Chamber method) |

Pressure accumulation method |

(3)Bombing method (The method that the search gas flows into and out from the test work)

This method is used for the leak test of a test work that is sealed. The test work is put in a pressurized container, and the pressurized container is filled with the search gas and kept in this state for a certain time. If there is a leak, the search gas flows into the test work. Then, the test work is put in the vacuum chamber and evacuated. If the test work leaks, the search gas flows out of the test work. This method detects this outflowing search gas.

We learned that there are many different methods of leak test.

For example, manufacturers use the vacuum chamber method (bell jar method/chamber method) when inspecting air conditioners for leaks. After the products pass the inspection, manufacturers fill refrigerant and use the halogen leak test to check for the refrigerant leak.

Manufacturers use the sniffer method to identify the leaking location of the failed products and fix the leak. After that, manufacturers use the vacuum chamber method to check for the leak again.

Lifestyle

-

Protect nutrients by preventing oxidation with a vacuum chilled

-

#05 Helium Leak Detector

-

#04 Gas Leak Detection Methods

-

#03 Classification of Leak Detection Methods

-

Built-in small diaphragm pump for tasty and long-hour storage

-

#02 The Importance of Refrigerant Leak Detection

-

#01 How The Air Conditioner Works

Solution

- Big Science

- Lifestyle

- Technology

- Medical Field