What is CRTM?

CRTM stands for Crystal Rate Thickness Monitor, and it's ULVAC's Quartz Crystal Oscillation Type Deposition Controller. This name (it's so long, isn't it?) factors as bellow;

- "Quartz Crystal Oscillation Type" works with quartz plates vibration.

- "Deposition" is for film deposition processes

- "Controller" is for controlling devices

What is Quartz Crystal Oscillation?

Quartz crystal is a colorless and transparent crystal formed of silicon dioxide. Quartz crystal has two main features;

- The quartz crystal under mechanical pressure produces electricity on the surface, called Piezoelectric Effect.

- The quartz crystal applied voltage is deformed, called Inverse Piezoelectric Effect.

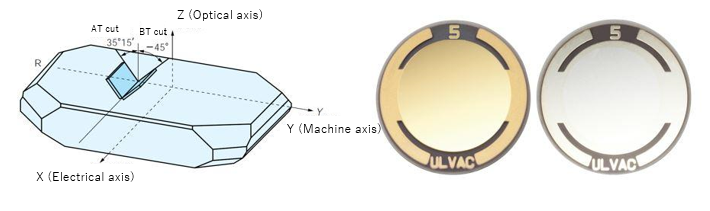

Both sides of the quartz crystal plate cut from at a specific angle are applied voltage, starting a certain vibration called Resonance.

ULVAC's CRTS forms electrodes of gold and silver films on a 12.4 mm diameter quartz crystal palate's surface.

How CRTM Works?

Going straight to the point, CRTM automates the deposition process.

But, HOW? The key principle is Quartz Crystal Oscillation, sliding vibration of the quartz crystal plate. Let's get that step by step.

What determines the vibration frequency of the quartz crystal plates? The formation such as cutting angle and thickness does. When it comes to ULVAC's quartz crystal plates vibrate 4MHz, 5MHz, or 6MHz. 5MHz means it vibrates 5 million times/sec. It vibrates and catches substances on the surface. So, What's happening next?

- Mass increases, getting heavy.

- Vibrating gets dull.

- The more mass increases, the fewer frequency decreases. (Hz)

- Changing frequency indicates the mass (g) of substances on the quartz crystal plate.

- The substance attached area and material density calculate the thickness of the substances. (Å, nm)

- The thickness of the laminated film and that speed time determine the deposition speed rate. (Å/sec)

In conclusion, CRTM is available to calculate and confirm 3 key indications to automatically operate the deposition processes.

(1) Hz: Frequency

Measuring the frequency catches up drastically changes and the product life.

(2) Å: Laminate Thickness

Calculating the laminate thickness predicts process endpoints and film thickness of multilayer film deposition.

(3) (Å/s): Rate

The rate feedbacks to the deposition power supply. Furthermore, controlling the rate improves the film quality.