ULVAC's new quartz crystal plate, which allows the successful deposition process, has better temperature characteristics during deposition than conventional quartz plates, less rate fluctuation due to radiant heat, and improved reproducibility.

It is developed to extend product life, improve stability, control, and deposition control.

- 1. Features of new quartz crystal plates.

- 2. Problems of deposition process control of Quartz Crystal Oscillation Type Deposition Controller.

- 3. Recent market needs

- 4. Responding to market needs

- 5. Products introduction

Features of new quartz crystal plates

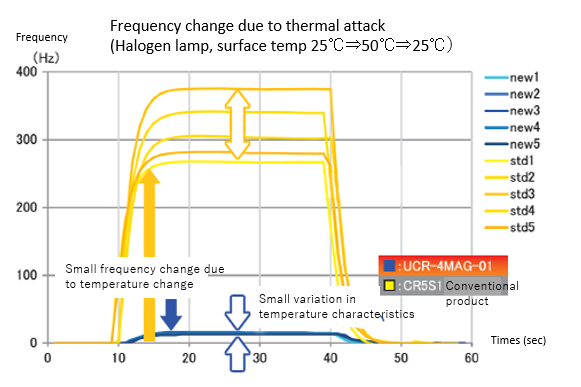

■Frequency change due to radiant heat is the smallest in the class

- Excellent temperature characteristics during deposition.

- Excellent rate stability and long product life.

- The fluctuation or change (changes in thermal shock) when opening and closing the shutter is small.

■High-Performance quartz crystal plates specialized for organic materials. (UCR-4MAG-01)

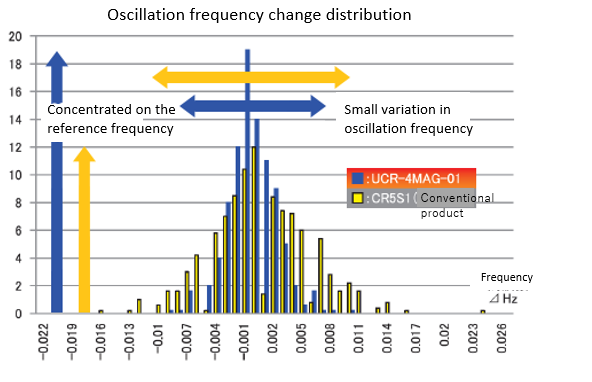

- Less variation in sensitivity, rate, and characteristics of individual quartz crystal plates.

- Ideal for applications that use multi-sensor switching.

- Compared with the 5 MHz frequency specification, the 4 MHz specification has a longer life.

■Adoption of a rotation type case

- 1 pack contains 12 pieces

- Easy management of quartz crystal plates. (Reduction of damage during transfer/storage)

Problems of deposition process control of Quartz Crystal Oscillation Type Deposition Controller.

The frequency changed after changing the quartz crystal plate.

It is a new quartz crystal plate, but the oscillation frequency is not the same.

■Many factors determine the oscillation frequency...

quartz crystal plate, cut angle, shape, and surface treatment

electrode, material, area, thickness, shape

sensor, the contact state between quartz crystal plate and sensor electrode.

There are subtle individual differences in quartz crystal plates.

Not only actual deposition but also other factors cause the frequency change.

Recent market needs

In new markets such as OLED panels, there are some cases that "unstable elements" which could have been overlooked in the past can no longer be ignored.

・I want to control the rate below Å.

・I want to deposit a film at a low deposition rate.

・I want to reduce variations in the film thickness down to a few%.

・I want to deposit dozens of layers of very thin films.

It is necessary to eliminate and improve the unstable elements of frequency measurement.

Responding to market needs

- Improvement of frequency change elements

・Individual differences of quartz crystal plates

・Temperature characteristic - Other Improvements

・Adhesion and affinity of laminates

・Usage, storage, and transport conditions

There is a way to improve the stability by software arithmetic processing, however,

It is not a real solution

Products introduction

The new quartz crystal plate UCR series reduces conventional problems by incorporating the know-how of ULVAC and providing excellent temperature characteristics and frequency uniformity.

1. Advantages of UCR Series

Frequency change due to radiant heat is the smallest in the class.

Frequency distribution due to individual differences of quartz crystal plate is small.

Improved Reproducibility Little variation

Improved safety Small change in temperature characteristics

Improved film quality Stable operation until measurement limit

Long-life Longer life of the quartz crystal plate

Improved productivity Longer equipment operating time

More stable deposition under various conditions

2. UCR series response process

Metal :AL、Cu、Au、Ag、Ni、Ti、Cr ...etc

Oxide : SiO2、ZrO2、AL2O3...etc

Organic material: OLED panel

The new quartz crystal plates are available in 4 MHz and 5 MHz and can be applied to various deposition processes.

The new quartz crystal plates are incorporated ULVAC's unique technologies and achievements and contribute to improving the deposition process quality and tact.

3. Specifications of Quartz crystal plate UCR

| Model | UCR-4MAG-12 | UCR-5MAU-12 | UCR-5MAG12 |

| Application | Organic Material Film (OLED Panel) |

Metal Film, Optical Film | |

| Frequency | 4MHz | 5MHz | |

| Diameter | φ12.4 | ||

| Electrode | Ag | Au | Ag |

| Supported Deposition Controller |

CRTM-9200 | CRTM-6000G/CRTM-9200 | |

| Sensor | Single-Sensor (CRTS-4, 6, 0, 4U, 6U) Multi-Sensor (CRTS-12NS, M6) |

||

| Electrode Surface | Mirror Finish | Standard | |

| Package | Multi-Sensor Friendly Case (12pcs) | ||