Troubleshooting

Cryopump | Safety Instructions

1. Cautions about pressure

A cryopump can store a large number of condensable gases inside.

However, it is dangerous to warm up a sealed cryopump as the inner pressure may reach several MPEGs. To prevent an explosion, the CRYO-U cryopump is provided with a pressure relief valve which starts opening at 10kPa(gage) and fully opens at 20kPa(gage). Following precautions on pressure relief valve must be observed for operating cryopumps safely.

- Do not block the pressure relief valve.

- Do not strengthen the spring of the pressure relief valve.

- Do not use it for another purpose (for example, as a roughing port or a gauge port).

- Connect the pressure relief valve to the exhaust line.

- The KF25 flange is mounted on a pressure relief valve to connect an exhaust line.

- Clean the pressure relief valve after regeneration.

- If the pressure relief valve contains dust and dirt, they will stick to the pressure relief valve seat and cause leakage.

2. Pumping flammable or explosive gases

The pumped gases are released into the cryopump again by regeneration or warming up since cryopumps are capture pumps. In most cases, it is very likely to be a mixture containing another type of gas, especially air. If the mixture of flammable gas and air is released into the pump during regeneration, there is a risk of combustion or explosion if there is a source of ignition. Possible causes of ignition in the vacuum equipment are the following:

- Ignition by a vacuum gauge filament being turned on

- Ignition by a heater or the like

- Ignition by static electricity

If roughing pipe and exhaust line are made of plastic such as vinyl chloride, etc., it may produce static electricity. Therefore, we strongly recommend using metallic pipes and ducts which are grounded. Be sure that the ground resistance of the piping is less than 100Ω.

Table 1:Combustion range and detonation range of major gases (Volume percentage against air)

| Gas | Molecular Weight | Specific Gravity 0℃,1atm |

Boiling Point K |

Combustion Range Vol % |

Detonation Range Vol % |

|---|---|---|---|---|---|

| Hydrogen H2 | 2.016 | 0.070 | 20.3 | 4.0~75.0 | 18.3~59 |

| Carbon Monoxide CO | 28.01 | 0.97 | 81.7 | 12.5~74.0 | - |

| Hydrogen Sulfide H2S | 34.08 | 1.19 | 213.6 | 4.3~45.0 | - |

| Silane SiH4 | 32.14 | 1.107 | 161.2 | 0.8~98 | - |

| Arsine AsH3 | 77.94 | 2.692 | 210.7 | 0.8~98 | - |

| Phosphine PH3 | 34.00 | 1.146 | 185.5 | 1.3~98 | - |

| Diborane B2H6 | 27.67 | 0.955 | 180.7 | 0.8~98 | - |

| Ammonium NH3 | 17.03 | 0.59 | 239.8 | 15~28 | - |

| Methane CH4 | 16.04 | 0.555 | 111.6 | 5.3~14 | - |

| Ethane C2H6 | 30.07 | 1.04 | 184.6 | 3.0~12.5 | - |

| Propane C3H8 | 44.10 | 1.550 | 231.1 | 2.2~9.5 | - |

| Ethylene C2H4 | 28.05 | 0.978 | 169.5 | 3.1~32 | - |

| Acetylene C2H2 | 26.04 | 0.907 | 198.2 | 2.5~100 | 4.2~50 |

Table 2:Combustion range and detonation range of mixture of oxygen and inflammable gas

| Gas | Combustion Range(Vol %) | Detonation Range(Vol %) |

|---|---|---|

| Hydrogen | 4~94 | 15~90 |

| Acetylene | 2.3~94.5 | 3.5~93 |

| Methane | 5.1~61 | - |

| Propane | 2.3~55 | 3.7~37 |

| Carbon Monoxide | 15.5~94 | 38~90 |

| Ammonium | 15~79 | 25.4~75 |

3. Cryopump oxygen procedures

Combustion supported by oxygen in the pump could cause severe injury. When oxygen is used as a process gas, special precautions described below should be taken.

1. When handling CRYO-U Cryopump, follow all the instructions described in this manual including:

*Ensure that there are no sources of ignition (e.g. hot filament vacuum gauges) on the cryopump side during regeneration, thus, turn off all switches of the attached measures.

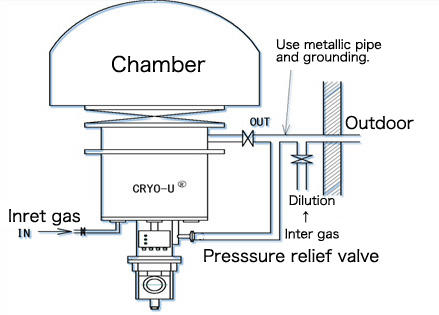

Refer to Figure 1 for the following cautions:

①Be sure to use a metallic pipe or duct and to ground the piping for gases discharged from the cryopump in order not to produce static electricity.

②Perform inert gas purge regenerations at flow rates recommended for cryopumps.

③Perform inert gas purge (such as N2, etc.) into the exhaust line to dilute the flammable gas concentration below its combustion range before exhaust them away to the atmosphere.

④Perform inert gas purge into both the exhaust line and cryopump as regeneration starts. Ensure that there is no oxygen in the pipe when discharging gases from the cryopump.

⑤In case the pressure relief valve blows, connect the pressure relief valve to the exhaust line to dilute the discharged gases by inert gas.

2. Regenerate as frequently and periodically as practical to minimize the amount of oxidizer present in the cryopump.

3. Ensure that the oxygen concentration in the cryopump is lower than it in the atmosphere when roughing the cryopump. (For example, it is richer-than air oxygen levels just after power failure.)

Do not rough pumping before diluting the discharged gases with inert gas.

To precede regeneration more safely, change the lubricating oil to inorganic oil which hardly reacts with oxygen such as FOMBLINE (Perfluoro Polyether vacuum pump fluid) in case of using rotary vacuum pump as a roughing pump, or use dry-sealed vacuum pump.

If power failure occurred, always perform an inert gas purge before vacuuming the chamber.

NOTE: Explosion occurring from ozone in the cryopump could cause severe

injury. Ozone can be present as a by-product when using oxygen as a process gas.

Ozone may be unknowingly produced in the ionizing process (e.g., sputtering, etching, glow discharge, EB deposition). There is a risk of explosion if ozone is present, especially during regeneration of the cryopump.

The followings are the sign of ozone evolution.

1. Cracking/popping sounds (as in electrical arching) occurring within the first few minutes of regeneration.

2. Gas discharged from cryopump during regeneration has a pungent odor, similar to that produced in the arc welding operation.

NOTE: Changes in the process may increase the amount of ozone present. Explosion occurring from large quantities of ozone could cause severe injury.

If ozone is present, the following precautions must be observed:

1. Follow all oxygen precautions mentioned above. Regenerate as frequently as practical to minimize the amount of ozone in the cryopump. The required regeneration cycle depends on the flow rate and process conditions. Daily regeneration may be required.

2. Reduce the amount of oxygen to the minimum as far as the process will allow.

When oxygen is used as a process gas, please consult with your equipment manufacturer or ULVAC CRYOGENICS for technical assistance.

In case of power failure, make the wiring of the control circuit with UPS to perform an inert gas purge into both the exhaust line and the cryopump. For this reason, a permanent power supply is required. The thermometer, the purge N2 gas valve to the cryopump, the discharge valve from the cryopump, the atmospheric pressure sensor in the cryopump, and the valve introducing N2 gas into the exhaust line are minimum needs of UPS.

After a power failure, check the temperature of the 2nd stage of the cryopump and decide whether or not to regenerate the cryopump. If the temperature of the 2nd stage exceeds 20K, perform regeneration. If 20K or less, restart the cryopump.

Figure 1:Dilution of Oxygen/Inflammable Gas (1)

4. Regeneration after pumping flammable gases

Use special cautions when performing regeneration of cryopump after pumping flammable gases. (Including flammable gases produced in the vacuum chamber as a result of plasma reaction or the like.)

Typical examples of hydrogen generation are as follows:

・Formed in the decomposition of process gas

・Released from target material or vapor deposition material

・Formed in the decomposition of outgassing (H2O) from substrate or contents

When performing regeneration using a rotary pump after pumping flammable gases, there is a danger of combustion or explosion if the flammable gases are mixed with the air at the exhaust port or duct of the rotary pump and there is a source of ignition. However, if the combustion range of the flammable gases(See Table 2) is within its normal limit, there is no danger of combustion or explosion.

When regenerating cryopump captured flammable gases, special precautions described below should be taken as mentioned in Section 3, Cryopump Oxygen Procedures.

*Ensure that there are no sources of ignition (e.g. hot filament vacuum gauges) on the cryopump side during regeneration, thus, turn off all switches of the attached meters.

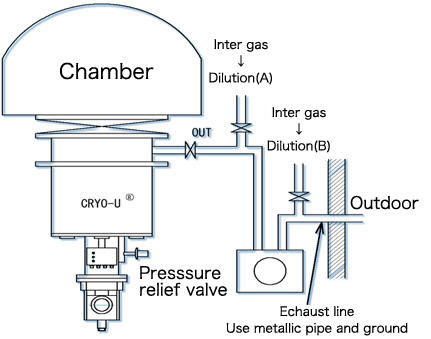

Refer to Figure 2 for the following cautions:

①Be sure to use a metallic pipe or duct and to ground the piping for gases discharged from the cryopump in order not to produce static electricity.

②Perform inert gas purge regenerations at flow rates recommended for cryopumps.

③Perform inert gas purge (such as N2, etc.) into exhaust line to dilute the flammable gas concentration below its combustion range before exhaust them away to the atmosphere.

④Perform inert gas purge as regeneration starts. Ensure that there is no oxygen in the pipe of the exhaust line when discharging pumped gases into the pipe.

⑤In case the pressure relief valve blows, connect the pressure relief valve to the exhaust line to dilute the discharged gases by inert gas.

⑥If power failure occurred, always perform an inert gas purge before rough pumping the chamber.

⑦The regeneration period should be decided by the capacity of N2 dilution of the inflammable gas in the cryopump. N2 dilution means introducing inert gas into both the exhaust line and the cryopump.

When flammable gases are used, please consult with your equipment manufacturer or ULVAC CRYOGENICS for technical assistance.

Make wiring of the control circuit with UPS to perform an inert gas purge into both the exhaust line and the cryopump in case of power failure. For this reason, a permanent power supply is required. The thermometer, the purge N2 gas valve to the cryopump, the discharge valve from the cryopump, the atmospheric pressure sensor in the cryopump, and the valve introducing N2 gas into the exhaust line are required at least.

After a power failure, check the temperature of the 2nd stage of the cryopump and decide whether or not to regenerate the cryopump. If the temperature of the 2nd stage exceeds 20K, perform regeneration. If 20K or less, restart the cryopump.

When evacuating flammable gas from cryopump by rotary pump, evacuate it at a very low rate. Be sure that the concentration of flammable gas in the duct is lower than its combustion range given in Table 2. Introduce inert gas from "B" in Figure 3.

When the cryopump has pumped a large amount of oxygen and its concentration in the cryopump is higher than 20% during regeneration, there is a danger of combustion or explosion of rotary pump oil. In this case, perform an inert gas purge(such as nitrogen or the like) into the roughing line between cryopump and rotary pump to keep the oxygen concentration lower than 20%. (Figure 3: Inert gas purge from "A".)

When discharging flammable gas from cryopump with air or oxygen at the same time, stop pumping the gas before the flammable gas concentration comes within the combustion range even if the inflammable gas returns to a gaseous state. For safety operation, perform inert gas purge into the roughing line from "A" and "B" in Figure 3.

Figure 2:Dilution of Oxygen/Inflammable Gas(2)

Troubleshooting

HOW TO

- Vacuum Tech Basics

- Fundamentals of Vacuum Pumps (Low to Medium Vacuum)

- Fundamentals of Vacuum Pumps (High Vacuum)

- Fundamentals of Vacuum Valves

- Fundamentals of Vacuum Gauges

- Fundamentals of Quartz Crystal Oscillation Type Deposition Controller

- Fundamentals of Leak Detection

- Fundamentals of High-Speed Spectroscopic Ellipsometer

- Fundamentals of Gas Analyzer (Process Gas Monitor)

- The Others

- How to Choose The Best Products

- Old Models vs. New Models

- Troubleshooting