Technology

Launch of Cryogenic trap using a helium refrigerator to replace CFC substitute cold trap

[Technical Information of Cryopumps 1 ]

Launch of Cryogenic traps using a helium refrigerator to replace CFC substitute cold traps

October 27th, 2000

-First in the industry, it can cool and raise the temperature within 10 minutes-

Launch of Cryogenic traps using a helium refrigerator to replace CFC substitute cold traps

We launched the Cryogenic Super Trap(speed series TS type, pumping speed for water molecules 10,000~100,000L/s ) using a helium refrigerator to replace the CFC substitute cold trap.

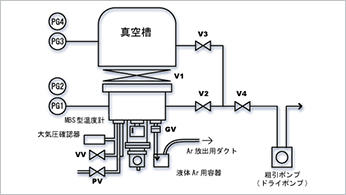

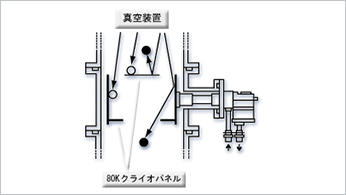

Batch-type vacuum equipment and film deposition equipment for optics have cryogenic surfaces in the deposition chamber or in the exhaust line between the main valve and the deposition chamber to reduce the pumping time and the partial pressure of the moisture in order to efficiently pump the moisture that is discharged from the substrate during pumping and deposition.

Vacuum deposition is used to produce automobile parts such as mirrors, radiators, handles, and switches, high-priced precision parts such as eyeglasses, watch covers, and cameras, and daily commodities such as containers of cosmetics and decorative materials. When these are deposited, the CFC substitute cold traps is used because a large number of water molecules are generated.

Although it is said that CFC substitutes (HFC) do not destroy the ozone layer, they are said to have a greenhouse effect that is Hundreds to tens of thousands of times greater than CO2. CFC substitutes (HFC) were the focus of the Kyoto Conference on Global Warming.

Helium gas used in this product has zero ozone layer depletion coefficient and zero global warming potential, and has no environmental problems.

It has been technically difficult for small refrigerators that use helium gas to cool in a short time, like the CFC substitute cold traps do. We succeeded in developing a large refrigerator and commercialized a trap that is the global environment-friendly and replaces the CFC substitute cold trap.

The new TS model is designed to perform better than conventional CFC substitute cold traps and can reach temperatures between 100K (Kelvin) and 130K. It is an innovative trap that can complete both cooling and raising the temperature within 10 minutes, which was previously impossible.

Besides, compared with the compressors used for CFC substitute cold traps, the compressors used for TS type traps are smaller and lighter, and can be installed anywhere. The refrigerant pipe does not require insulation, so condensation is no longer a concern. Moreover, the standard lead time is as short as 1.5 months, and the low price is a big advantage.

ULVAC's nationwide service network is available, and the service system will be expanded to other countries such as South Korea and Taiwan.

It is also easy to replace liquid nitrogen traps as well as CFC substitute cold traps you have already used. A patent is pending for the important technology.

Technology

-

Pioneering Hydrogen Leak Detection for a Sustainable Future: ULVAC's HELIOT 900

-

Reliable and Efficient Leak Detection Solutions for Battery Manufacturers: ULVAC's HELIOT 900

-

Introduction of Liquid Nitrogen Generator" EMP Series" and New Product" UMP-40W"

-

"LS Series" Dry Vacuum Pumps with High Pumping Speed and Low Power Consumption

-

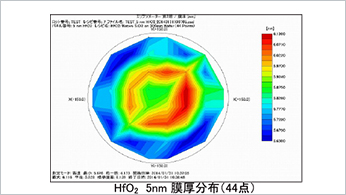

High-speed spectroscopic ellipsometer UNECS series measurement examples

-

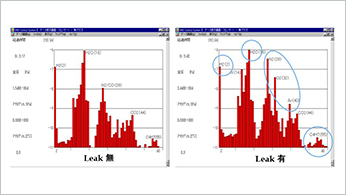

Applications of Process gas monitor.

-

Launch of Cryogenic trap using a helium refrigerator to replace CFC substitute cold trap

-

Rapid low-temperature regeneration ... Reduction of regeneration time.

-

Applications and examples of effective use of Super Traps

-

Liquid Nitrogen Generator in diverse fields

-

Vacuum Gauge ST2 Technical report

-

Liquid Nitrogen Generators | Technical Report

-

Development of a quartz crystal disc with a resonance frequency of 4 MHz

-

HELIOT900 | Technical report

-

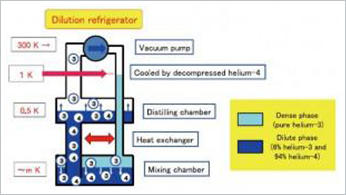

Cryogen Free Dilution Refrigerator using 4K-Cryocooler

Solution

- Big Science

- Lifestyle

- Technology

- Medical Field