Technology

Rapid low-temperature regeneration ... Reduction of regeneration time.

Principle

Like sputtering equipment, when the pumping capacity for argon determined the regeneration cycle of the cryopump, the cryopump can pump again after discharging only the argon and hydrogen from the cryopumps.

Hydrogen becomes a gas easily and is released when the temperature is raised above 50 K. Argon liquefies when the temperature is raised above 100 K. A method of regenerating a cryopump by discharging gaseous hydrogen and liquid argon while maintaining the cryopump in a low-temperature state is rapid low-temperature regeneration.

However, since water is left as ice in the pump(the temperature is raised to room temperature when the amount of water increases.), normal regeneration is required.

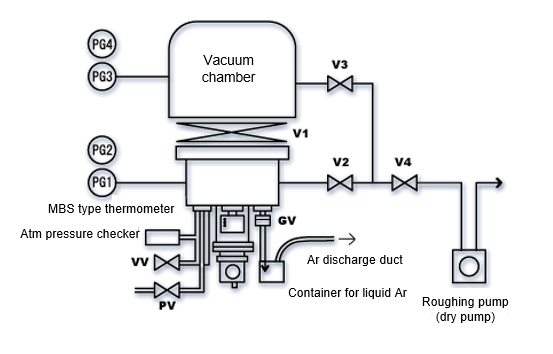

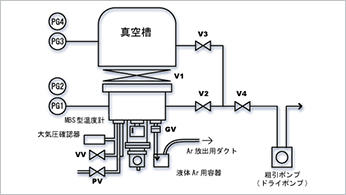

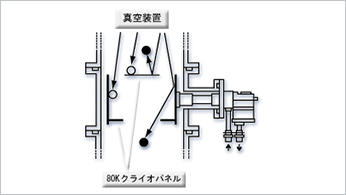

Low-temperature regeneration requires a mechanism for discharging liquefied gas from a cryopump. (Figure 2-1)

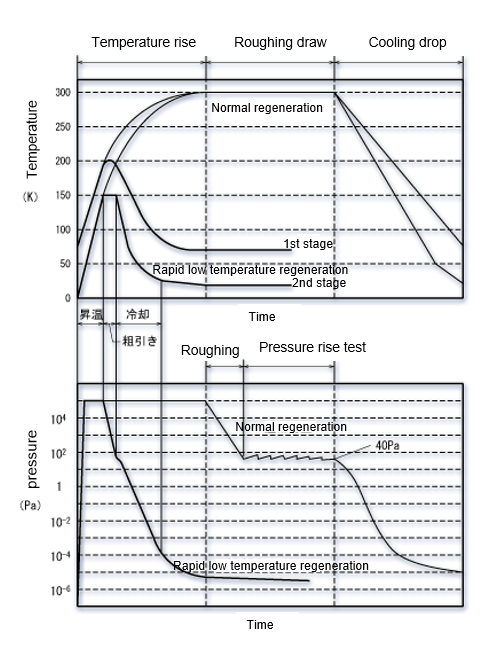

In the low-temperature regeneration, it is not necessary to raise the temperature to room temperature, so the time of temperature rise is short. Moreover, since cooling starts from a low-temperature state, the regeneration time can be remarkably shortened.

In a test of rapid low-temperature regeneration which was performed using a 12" type cryopump, the cryopump was ready for pumping within 1 hour after shutting down it. As in this example, in the case of sputtering equipment, the regeneration time can be drastically shortened by rapid low-temperature regeneration. ( 1/4 to 1/5 of normal time)

In addition to the sputtering equipment, in the case that the regeneration cycle is determined by a condensable gas other than water, the rapid low-temperature regeneration is very effective to reduce the regeneration time drastically.

Figure2-1: Example of a pumping system of rapid low-temperature regeneration

| HVP:Hydrogen vapor pressure thermometer | PG4:Ionization gauge for vacuum chamber | V4:Roughing valve. |

| PG1:Pirani gauge for cryopump | V1:Main valve | GV:Gate valve(Ar discharge valve) |

| PG2:Ionization gauge for cryopump | V2:Cryopump roughing valve | VV:Discharge valve |

| PG3:Pirani gauge for vacuum chamber | V3:Vacuum chamber roughing valve | PV:Introduction valve |

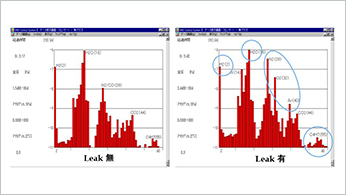

Figure 2-2:Comparison of Rapid Low-Temperature regeneration and Normal Regeneration

Technology

-

Pioneering Hydrogen Leak Detection for a Sustainable Future: ULVAC's HELIOT 900

-

Reliable and Efficient Leak Detection Solutions for Battery Manufacturers: ULVAC's HELIOT 900

-

Introduction of Liquid Nitrogen Generator" EMP Series" and New Product" UMP-40W"

-

"LS Series" Dry Vacuum Pumps with High Pumping Speed and Low Power Consumption

-

High-speed spectroscopic ellipsometer UNECS series measurement examples

-

Applications of Process gas monitor.

-

Launch of Cryogenic trap using a helium refrigerator to replace CFC substitute cold trap

-

Rapid low-temperature regeneration ... Reduction of regeneration time.

-

Applications and examples of effective use of Super Traps

-

Liquid Nitrogen Generator in diverse fields

-

Vacuum Gauge ST2 Technical report

-

Liquid Nitrogen Generators | Technical Report

-

Development of a quartz crystal disc with a resonance frequency of 4 MHz

-

HELIOT900 | Technical report

-

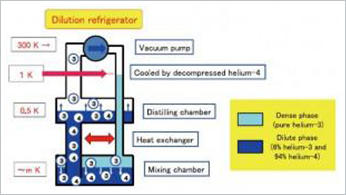

Cryogen Free Dilution Refrigerator using 4K-Cryocooler

Solution

- Big Science

- Lifestyle

- Technology

- Medical Field