Technology

Applications and examples of effective use of Super Traps

1. Introduction

In the case of a regular vacuum device, since the main component of the exhaust gas is water, the pumping speed of the water of the vacuum pump used in the device determines the pumping time and the ultimate pressure of the device.

For example, since the pumping speed of water of a turbo molecular pump is not large, it takes a long time to reach a predetermined pressure when the pumping starts from an air-exposed state.

In the case of a diffusion pump, the pumping speed of water also decreases since a cold-water baffle is used to prevent the backflow of oil vapor.

Also, a trap that is cooled with liquid nitrogen is used to prevent the backflow of oil vapor, and in this case, the maximum pumping speed of water is the same as that of a cryopump. However, an increase in operating costs due to the consumption of liquid nitrogen is a problem.

Refrigeration baffles and traps that use Freon refrigerators may be used instead of liquid nitrogen. However, the use of Freon is being restricted due to its impact on the global environment, and it is expected that the use of Freon will be difficult in the future. Although the refrigeration capacity of the Freon refrigerator is large, the performance deteriorates in the high vacuum region because the ultimate temperature of the Freon refrigerator is about 140 K.

Super Trap uses a small helium refrigerator, so there is no risk of environmental destruction at all. It can cool to below 80 K and can be used in a wide range of vacuum region from low to ultra-high vacuum. Because of these features, Super Trap is used to improve the pumping performance of turbo molecular pumps, as a trap of diffusion pumps, and as a special vacuum pump to pump the water.

In this section, we explain the structure and performance of Super Trap and provide examples of its application and effects.

2. Structure of Super Traps and Principle of Exhaust

The refrigerator system used for Super Trap is composed of a compact G-M cycle helium refrigerator and a compressor. A two-stage refrigerator used for a cryopump is remodeled into the single stage small G-M cycle helium refrigerator.

The single stage of the refrigerator is cooled to below 80K, and an 80 K cryopanel attached here condenses and pumps a gas with a low vapor pressure such as water.

The temperature of the 80K cryopanel can be determined by CA thermocouples.

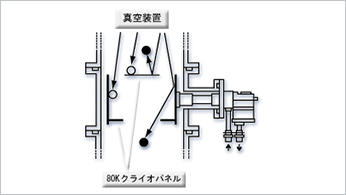

There are two types of Super Traps: a pass type that allows gas to pass through, such as the liquid nitrogen trap of a diffusion pump, and a direct-attach type that is directly attached to a vacuum device.

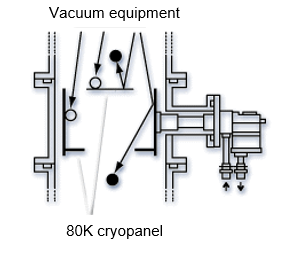

The pass type (Figure. 1) is used in series with a cryopump and a diffusion pump and is used to increase the pumping capacity of water of the vacuum pump.

In this case, since the exhaust resistance is applied to a gas that is not exhausted by an 80 K cryopanel such as nitrogen and argon, it is necessary to set the appropriate conductance.

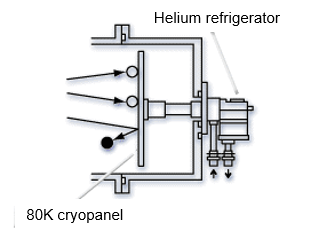

On the other hand, the direct-attach type (Figure. 2) is a type mounted directly on the wall of the vacuum chamber or through a valve and is independent of the pumping system. It is installed in parallel with the pumping system.

In this case, the pumping speed of the pumping system is kept as it is, and only the pumping speed of the water can be increased.In terms of water, the same pumping performance as when one cryopump is added can be achieved, and water can be exhausted most efficiently. Besides, since problems such as conductance do not occur, the structure and handling are simple.

Figure 1: Structure of pass type Super Trap. |

Figure 2:Structure of direct-attach type Super Trap |

3. Regeneration of Super Traps

As the amount of water condensed on an 80 K cryopanel increases, the surface temperature of ice increases. When the surface temperature of ice exceeds 130 K, the pumping performance decreases, so regeneration to remove ice is required. Regeneration can be done by stopping the refrigerator and raising the temperature of the 80 K cryopanel to room temperature to melt ice and discharge it to the outside.

The temperature during regeneration is raised naturally after the vacuum is broken, but If the heating time is to be shortened, the band heater can be attached to the outside of the vacuum chamber of Super Trap and heated. After the ice is exhausted to the outside, Super Trap is vacuum evacuated to start and cool. When the temperature of the cryopanel drops below 130 K, the water can be exhausted again.

4. Applications of Super Traps

Diffusion pumps are used when a large number of contaminants, such as oil vapor need to be exhausted from the vacuum system. However, as mentioned above, since turbo molecular pumps and diffusion pumps have a small pumping speed of the water, Super Traps are used to compensate for these disadvantages. The main applications are the following.

(1) Special pumps to exhaust the water

Vacuum brazing furnace, Vacuum heat treatment furnace, Roll-to-Roll continuous deposition equipment, Deposition equipment, Sputtering equipment, Ion plating equipment.

(2) )Improvement of pumping system performance

Improvement of the performance of diffusion pumps, replacement of liquid nitrogen traps of diffusion pumps, and improvement of the performance of turbo molecular pumps.

Especially, In the case of film deposition on glasses, plastics, and ceramics, Super Trap is very useful because a large amount of water is discharged.

The super trap can be easily installed even on equipment that does not have a trap as long as there is a space to install, and can reduce the pumping time drastically.

5. Application to diffusion pumps

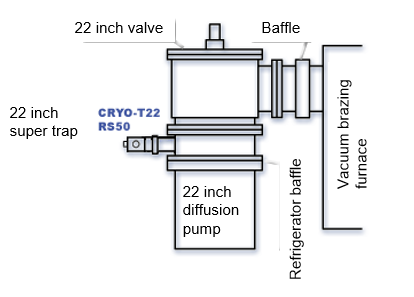

Figure. 3 shows an example of a 22 inches Super Trap CRYO-T22 installed to a vacuum brazing furnace with a 22 inches diffusion pump.

Figure. 3:Installation example on a diffusion pump.

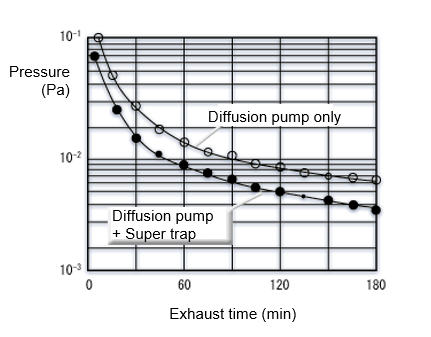

The target pressure for this device is 6.7×10-3Pa, but it took about 160 minutes to reach this pressure before Super Trap was installed. By installing Super Trap, the pumping time was shortened to 1/2. (see Figure 4)

Figure 4: Effect of Super Trap on Diffusion Pump

When Super Trap is used for a diffusion pump, it is necessary to use a device such as a water-cooled baffle between Super Trap and the diffusion pump to block radiant heat from the diffusion pump.

6. Application to sputtering equipment

Sputtering equipment introduce a massive flow of argon and requires the range of 10-1Pa, so a conductance valve limits the pumping speed.

In this case, although the object is to limit the pumping speed of argon, the pumping speed of water is also restricted.

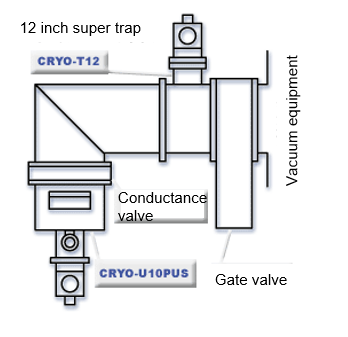

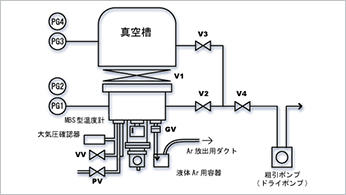

Figure. 5 shows an example in which Super Trap is used to solve this problem.

In this case, since the pumping speed of the water is not affected by the conductance of the conductance valve, the constant maximum pumping speed of the water is obtained, so that the partial pressure of the water in the film deposition chamber can be reduced.

Figure. 5 : Example of applications to sputtering equipment.

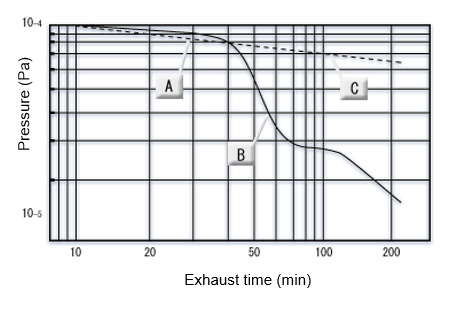

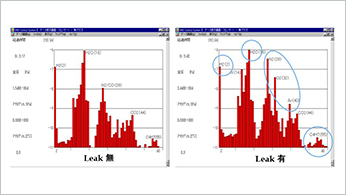

Figure. 6 shows the exhaust characteristics of this system when Super Trap is ON and OFF. When Super Trap is ON, the pressure decreased to about 1/4. Super Trap demonstrated the effectiveness in shortening the pumping time and lowering the ultimate pressure.

Figure. 6: Exhaust Characteristics of Sputtering equipment

7. Conclusion

There are many types of Super Traps (4 ~ 22 inches), which allows an economical system because one compressor can operate multiple small- and medium-sized super traps. (see Table 1)

Super traps are expected to be increasingly used in the future because of their high performance and wide application range.

| Diameter | Model | Refrigerator | Compressor |

|---|---|---|---|

| 6 | CRYO-T6 | RMS10 | C10T,C10AT |

| 8 | CRYO-T8 | RMS10 | C10T,C10AT |

| 10 | CRYO-T10 | RMS10 | C10T,C10AT |

| 14 | CRYO-T14 | RMS10,RMS50 | C10T,C10AT,C30VRT |

| 16 | CRYO-T16 | RMS50 | C30VRT |

| 20 | CRYO-T20 | RMS50 | C30VRT |

| 22 | CRYO-T22 | RMS50 | C30VRT |

Technology

-

Pioneering Hydrogen Leak Detection for a Sustainable Future: ULVAC's HELIOT 900

-

Reliable and Efficient Leak Detection Solutions for Battery Manufacturers: ULVAC's HELIOT 900

-

Introduction of Liquid Nitrogen Generator" EMP Series" and New Product" UMP-40W"

-

"LS Series" Dry Vacuum Pumps with High Pumping Speed and Low Power Consumption

-

High-speed spectroscopic ellipsometer UNECS series measurement examples

-

Applications of Process gas monitor.

-

Launch of Cryogenic trap using a helium refrigerator to replace CFC substitute cold trap

-

Rapid low-temperature regeneration ... Reduction of regeneration time.

-

Applications and examples of effective use of Super Traps

-

Liquid Nitrogen Generator in diverse fields

-

Vacuum Gauge ST2 Technical report

-

Liquid Nitrogen Generators | Technical Report

-

Development of a quartz crystal disc with a resonance frequency of 4 MHz

-

HELIOT900 | Technical report

-

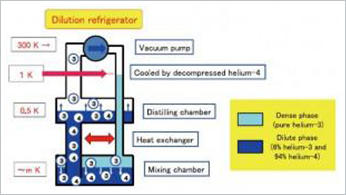

Cryogen Free Dilution Refrigerator using 4K-Cryocooler

Solution

- Big Science

- Lifestyle

- Technology

- Medical Field