Fundamentals of Vacuum Pumps (High Vacuum)

Cryopumps

Mechanism of Cryopump.

This pump features a clean vacuum and high pumping speed.

A cryopump is an accumulating type vacuum pump. The pump condenses and adsorbs gases on a cryogenic surface installed in the pump to create a condition from high vacuum to ultra-high vacuum.Also, this pump can obtain a clean vacuum that is not contaminated by oil and has a higher pumping speed than other vacuum pumps, which attracts attention.

Cryopump technology is used for the following applications!

Electronic components such as semiconductors, liquid crystals, and disks, eyeglass lenses, and extra-large space vacuum chamber.

Features of Cryopump.

Can a clean vacuum be obtained at a very low temperature?

Cryopump is a pump that condenses and adsorbs gas molecules on a cryogenic surface so that all gas molecules can be stored in the pump.

This pump does not have anything that works in a vacuum chamber. Since this pump does not use oil, it obtains a clean vacuum. Even though this pump is an adsorption type, its pumping speed is high. These are the main features of this pump.

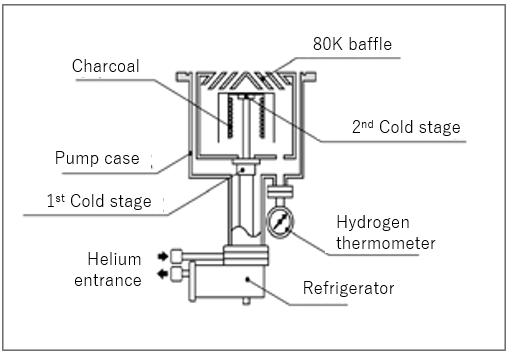

Mechanism of Cryopump.

Higher vacuum with two-stage.

Cold stage is a two-stage type. The cooling capacity of the first stage is large, and it can cool to 80 K (Kelvin) or less. First-stage exhausts mainly the moisture and the second stage exhausts molecules such as N2, O2, Ar, and H2 by cooling even further to obtain a higher vacuum.

The reason for the ultra-low temperature.

Gas molecules condense and adsorb on contact with a surface that is cooled close to 0K = absolute zero (-273.15 ° C).

How does a cryopump work?

1.What is a cryopump?

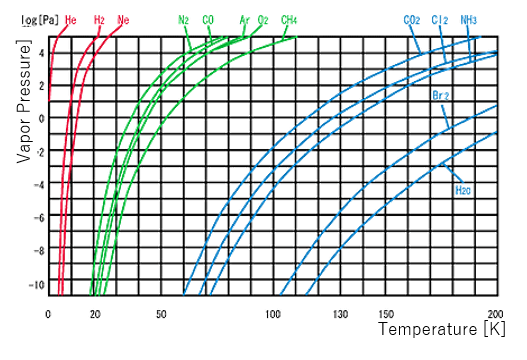

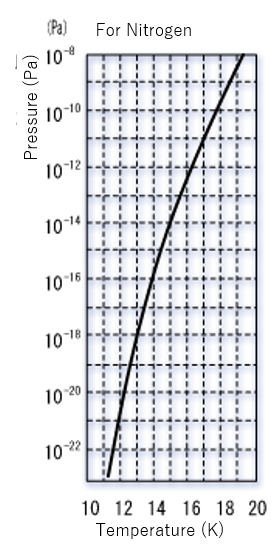

A cryopump is vacuum pump that traps gases and vapors by condensing them on a cold surface. For efficient evacuation under ultra-high vacuum, the vapor pressure for condensation, or the equilibrium pressure for adsorption must be less than 10-8Pa.Figure 1 shows vapor pressures of different gases.

According to this figure, if the cryocooled surface such as cryo-surface and cryopanel is cooled below 20K, the vapor pressure of the gas becomes below 10-8Pa, provided the vapor pressure is lower than that of nitrogen. The lightest gases such as hydrogen, helium, and neon are not condensed at 20K, therefore instead of relying on condensation alone, adsorbent made of special porous materials are provided to adsorb them. By cooling down the adsorbent below 20K, those gases are adsorbed efficiently, and thereby a cryopump can achieve ultra-high vacuum.

There are two ways to "cryocool" the surface of the cryopump. One is a use of coolant such as liquid nitrogen(LN2, 77K) or liquid helium(LHe, 4.2K), and the other is a small closed cycle helium refrigerator.

Figure 1:Vapor Pressures of Different Gases

A compact, closed cycle helium refrigerator can perform a long period stable operation without refilling of coolant. Also it can achieve clean and ultra-high vacuum with simple and straightforward operation.

2.Basic Principle and Structure

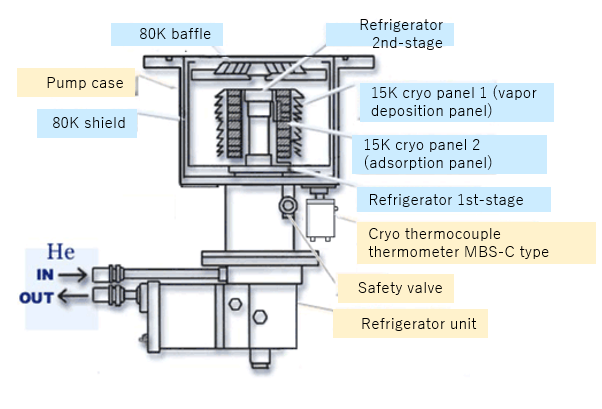

Let's take a look at CRYO-U8H as an example.

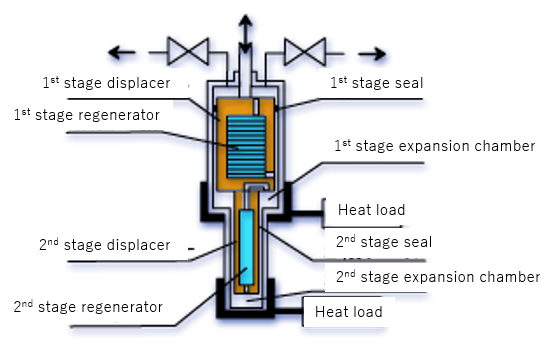

The refrigerator for CRYO-U cryopumps normally has two-stages. While the 1st stage has a large refrigerating capacity down to below 80K, the refrigerating capacity of the 2nd stage is small but cools down to 10 to 12K. Both 15K cryopanel(1) and 15K cryopanel(2) are mounted on the 2nd stage of the refrigerator, and shielded from the temperature radiation by the 80K shield and 80K baffle mounted on the 1st stage.

Figure2.CRYO-U8H

There are three types of gases pumped by cryopumps as follows.

| (1)Air(N2、O2) | :The residual gases after rough pumping the vacuum chamber. | ||

| (2)Outgas | 1 | H2O | :Adsorbed to the chamber wall.(The largest component in general vacuum system.)Major component of outgas from glass, plastic, and ceramic. |

| 2 | H2 | :Diffuses from inside of the metallic wall of the vacuum chamber.(Concerns in ultra-high or extreme high vacuum.)Outgas from high-temperature melted metal (especially Al) in deposition or sputtering process. | |

| 3 | CO、CO2、 CH4、CnHm |

:Fouling of the chamber wall. | |

| (3)Introduced Gas | 4 | Ar | :Sputtering Process |

| 5 | H2 | :Ion Implantation Process | |

| 6 | O2 | :Oxygenation | |

| 7 | Others | ||

As you see in Fig.1, the vapor pressure of water vapor becomes below 10-88 Pa at temperature of below 130K, and thus water vapor is pumped as a result of condensation on the 80K baffle and 80K shield. The next group of gases, nitrogen, oxygen, argon, and other gases of similar molecular weight are pumped at the exposed surface of 15K cryopanel(1) at the second stage, which is kept below 20K. The third group, mainly hydrogen, helium, and neon will not condense at 20K and will not be pumped efficiently by the metal surface because the equilibrium vapor pressure for cryosorption will be too high. To improve this situation, cryopumps have adsorbent of porous materials such as charcoal on the 2nd stage cryoarrays. The adsorbent is bonded to the inner surface of the 15K cryopanel(1) to prevent it from being covered with condensable gases.

Outside surface of 80K shield, 80K baffle, and 15K cryopanel(1) are specular finished in order to reflect radiant heat from room temperature. The inner surface of 80K shield is blackened to reduce the radiation heat transfer to the 15K cryopanel attached to the 2nd stage. In order that a cryopump to operate properly, both 80K shield and 80K baffle should be kept below 130K and 15K cryopanel to be kept below 20K.

In order to monitor those temperature, K(CA) thermocouple for 80K shield, and hydrogen vapor pressure gauge(H2VP) or CRYO METER MBS for 15K cryopanel are installed to the cryopumps. (The standard for the electromotive force at 130K of K(CA) thermocouple is -5.5mV.)

3.Regeneration and Pressure Relief Valve

Cryopumps are not continuous throughout pumps such as oil diffusion pumps and turbo molecular pumps. As a cryopump keeps gases inside on 15K cryopanels by condensation and adsorption, it needs to be degassed and regenerated on a regular basis. During this regeneration process, the cryopump is warmed up, and condensed or adsorbed gases are turned into gas again. If large amount of gases are pumped, there is a risk of explosion. In order to prevent the explosion danger, all cryopumps feature a pressure relief valve.

The operating pressure of the pressure relief valve has been set at 20kPa(gage).

For safety reasons, DO NOT BLOCK the pressure relief valve, and DO NOT MODIFY it for other purposes.

Also never use it as a purge valve in a regeneration process because refuse in purge gas may stick to the sheet of the pressure relief valve and may cause a leakage.

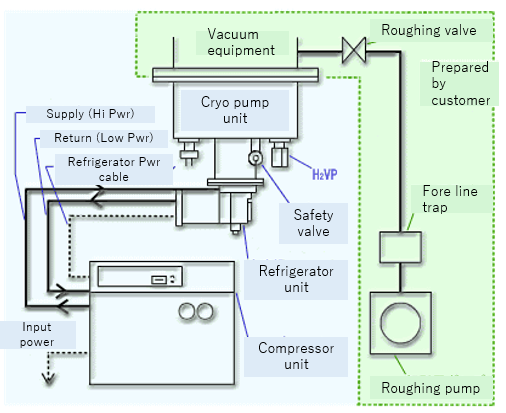

4.Cryopump System

Cryopump system consists of

《1》Cryopump Unit(incl. Cold Head)

《2》Compressor Unit

《3》Flexible Hose(2)

The connection of the cryopump system is shown in Figure 3. In addition, rough pump (customer-supplied) is necessary to operate and regenerate cryopumps. (Cryopumps cannot start from the atmospheric pressure.)

Figure3.Cryopump System

Performance Characteristics

The essential performance characteristics for cryopump operation are: ①Cooldown, ②Pumping Speed, ③Pumping Capacity, ④Maximum Throughput, ⑤Crossover Pressure, ⑥Ultimate Pressure, and ⑦Thermal Load Capacity. For details, see each section below.

1.Cooldown Characteristics

The vacuum chamber must be rough pumped before cryopumping since cryopumps cannot start its operation from atmospheric pressure. When rough pumping a CRYO-U® cryopump with a rotary pump, roughing pressure of 40Pa is sufficient since backflow of oil vapor will not occur. The residual gas will be adsorbed to adsorbent inside cryopump.Cooldown time differs depending on conditions as shown in table below.

Table 1.Factors which affects Cooldown Time

| Factor | Cooldown Time | |

|---|---|---|

| 1.Rough Pumping Pressure | HIGH | Extended |

| 2.Pump Temperature | HIGH | Extended |

| 3.Residual Gas Composition After Rough Pumping | DRY(Dry inside cryopump) | Extended |

| WATERY | Shortened | |

| 4.Contamination of Cryopump | CONTAMINATED | Extended |

Cooldown time is affected by regeneration method. Use of N2 purge or Band Heater may extend the cooldown time causing temperature rise, or dry condition which hardly achieves vacuum insulation. Also, slight leakage may cause extended cooldown time or cooldown failure.(Especially due to leakage from pressure relief valve.) Cooldown time may be reduced by 10 to 15% at 60Hz compared to that at 50Hz. Generally, cooldown time is defined as the amount of time for 15K cryopanel temperature to drop to 20K or below. See Table 2 for details.

2.Pumping Speed Characteristic

2-1.Pumping Speed for Water

It is usually assumed that the water condensation probability on cryosurface is approx. one, provided that the cryosurface temperature is below 150K. In normal operation, temperature of 80K shield and baffle is below 130K(80K or below in normal use). Therefore the pumping speed for water is equivalent to ideal pumping speed of cryopump which has a diameter of 80K shield. The ideal pumping speed (s) per unit area for molecular weight M is given by:

s=62.5/M1 / 2(L/s/cm2)(20℃)

Water molecular weight M is 18, thereby the ideal pumping speed(s) is 14.7(L/s・cm2).

Pumping speed for water(S) is given by S=s・A(L/s), provided the area of 80K shield inlet is A(cm2). For 8-inch cryopump, the area of 80K shield inlet is approx. 275cm2, thus, the pumping speed for water is 4000L/s. The same calculation is available for gases condensed and pumped on 80K baffle such as CO2 and NH4 etc.

CRYO-U8H pumping speed for water is 4000L/s. Since molecular weight of CO2 is 44, CRYO-U8H pumping speed for CO2 is given by:

SCO2=SH2O× (18/44)1/2=2560L/s

As you see, the capture probability(sticking coefficient) of condensing array for condensable gases is one, provided the temperature of cryosurface is below 20K. Also, cryopump pumping speed at molecular flow region is constant since the conductance from inlet to cryopanel is constant at molecular flow region.

The speed values given in brochures are pumping speed for nitrogen at molecular flow region. Pumping speed for condensable gases of molecular weight M other than nitrogen can be calculated by following equations.

SM=SN2×(28/M)2/1(L/s)。

Table 2.Pumping Speed of Various Cryopump for Nitrogen(Value from Brochure)

| Diameter | Model | Pumping Speed(L/s) |

|---|---|---|

| 6 | U6H | 2100 |

| 8 | U8H,U8H-U,U8HSP | 4000 |

| 10 | U10PU | 6900 |

| 12 | U12H,U12H-K2,U12HSP | 9500 |

| 16 | U16,U16P | 16000 |

| 20 | U20P | 29000 |

| 22 | U22H | 39000 |

| 30 | U30H | 70000 |

Pumping Characteristic for Argon and Nitrogen (Condensable Gas)

A group of gases such as N2、Ar、CO、O2 and other gases of similar molecular weight are condensed and pumped at 20K or below, therefore they are not condensed on 80K baffle and shield. In general, the limit temperature that gases can be pumped by condensation is 20K. The temperature of condensing array when condensation probability of gases becomes below one at 300K is:

N2 :approx. 23K

Ar :approx. 27K

Also, the temperature when cryopump loses its pumping ability is:

N2 :approx. 27K

Ar :approx. 29K

As you see, the capture probability(sticking coefficient) of condensing array for condensable gases is one, provided the temperature of cryosurface is below 20K. Also, cryopump pumping speed at molecular flow region is constant since the conductance from inlet to cryopanel is constant at molecular flow region.

The speed values given in brochures are pumping speed for nitrogen at molecular flow region. Pumping speed for condensable gases of molecular weight M other than nitrogen can be calculated by following equations.

SM=SN2×(28/M)1/ 2(L/s)・・・・・・・(1)

SN2:Pumping Speed for Nitrogen(L/s)

For example, CRYO-U8H pumping speed for argon is (See Table 2):

SN2=1700(L/s)and also molecular weight of argon is 40, thus, the calculation is:

Sar=1700X(28/40)1 / 2=1400L/s

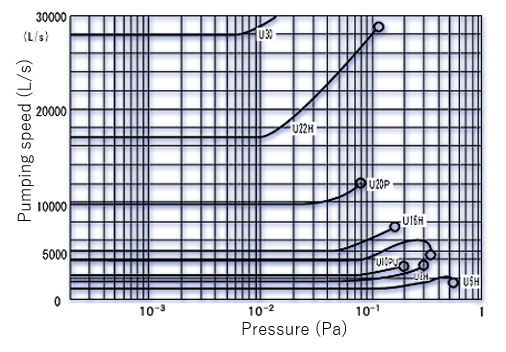

Figure 1.CRYO-U Pumping Speed for Nitrogen

| Model | Pumping Speed(L/s)(L/s) |

|---|---|

| U6H | 750 |

| U8H/U8H-U/U8HSP | 1700 |

| U10P | 2300 |

| U12H | 4000 |

| U12HSP | 4100 |

| U16/U16P | 5000 |

| U20P | 10000 |

| U22H | 17000 |

| U30H | 28000 |

Table 3.Pumping Speed of Various Cryopump for Nitrogen(Value from Brochure)

When gas flow changes from molecular flow to intermediate flow(transition flow), pumping speed increases since the conductance increases proportional to the pressure. However, since incoming heat increases as pressure increases, cryopump reaches its limit of pumping ability when the thermal load exceeds cold head refrigerating capacity. ULVAC CRYOGENICS defines the flow rate when the cryopanel reaches 20K by the thermal load as the maximum throughput.(The point marked "○" in Figure 2.) The maximum throughput may be increased with large refrigerating capacity, but it may generate temperature gradient in thickness direction since the thermal conductivity for cryoarray is limited even with a large refrigerating capacity. If the temperature of condensation array becomes too high exceeding its limit, gases will not be condensed, and then pumping capacity becomes zero. That is to say a physical limit of pumping.

2-3.Pumping Speed for Hydrogen, Helium, and Neon(Non-condensable Gas)

The next group of gases such as hydrogen, helium, and neon will not condense at 20K and will not be pumped efficiently by metal surface because the equilibrium vapor pressure for cryosorption will be too high. These gases cannot be pumped through condensation, therefore adsorbent cooled below 20K is provided to adsorb these gases. The pumping speed will decrease as the surface coverage increases. When the pumping speed is down to 80% of its starting value, the total amount of pumped gases is defined as the pumping capacity. (see below.) Pumping speed for non-condensable gases depends on the following:

(1)Adsorption Probability of Adsorbent Influenced Factors Below.

①Characteristics, Installation Method, and Configuration of Adsorbent

②Temperature and Amount of Adsorbent

③Rate of Degassing

④Kinds and Amount of Gases Previously Adsorbed

⑤Flow Rate and Temperature of Gases

(2)Arrival Rate of Gas from Inlet to Adsorbent (Conductance)

Typically the pumping speed is determined in accordance with test results. Pumping speed for gases with large amount of adsorption such as hydrogen and neon is constant at molecular flow region. Temperature of cryopanel rises as gas flow rate increases, and the flow rate at 20K is defined as the maximum throughput. For non-condensable gases, pumping at the maximum throughput or around may be performed for a short time because the adsorption probability decreases in a short time with increasing the amount of non-condensable gases adsorbed to the adsorbent. In case of pumping hydrogen at high flow rate, it is advisable to operate intermittently rather than continuously to maintain its pumping capacity.

Hydrogen, one of non-condensable gases, is not only a component of outgas but also vital for application, therefore specifications are determined in detail. There is few data for neon because it is not used in common. Also, for helium which is hardly likely adsorbed, it is not recommended to pump them by cryosorption since they can be pumped about 1% to 0.1% of hydrogen.

| Model CRYO-U |

Pumping Speed (L/s) |

Maximum Throughput (Pa・L/s) |

Pumping Capacity (Pa・L) |

|---|---|---|---|

| -U6H | 1100 | 1.1×102 | 3.1×105 |

| -U8H | 2700 | 2.4×102 | 1.0×106 |

| -U8HSP | 3200 | 2.4×102 | 1.0×106 |

| -U10PU | 3600 | 1.5×102 | 6.7×105 |

| -U12H | 6000 | 4.1×102 | 9.8×105 |

| -U12HSP | 6000 | 4.1×102 | 1.6×106 |

| -U16 | 10000 | 4.1×102 | 2.4×106 |

| -U16P | 10000 | 4.5×102 | 2.4×106 |

| -U20P | 18000 | 5.0×102 | 4.6×106 |

| -U22H | 25000 | 1.3×103 | 8.5×106 |

| -U30H | 43000 | 7.4×102 | 1.5×107 |

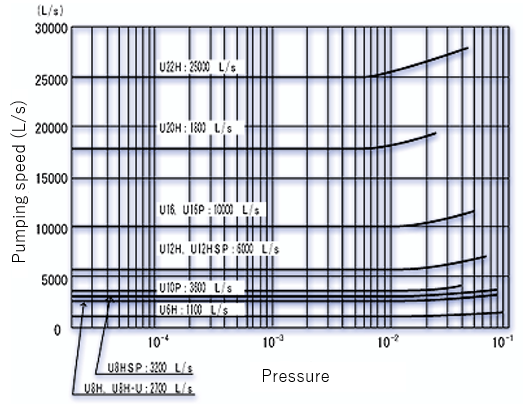

Table 4.CRYO-U Pumping Performance for Hydrogen

Figure 2.CRYO-U Pumping Speed for Hydrogen

3.Pumping Capacity of Cryopumps

Since a cryopump does not have a continuously functioning exhaust port, it has a limiting value of pumping. That is called the pumping capacity. When a cryopump becomes saturated, it is required to be regenerated because the performance degradation such as ultimate pressure rise and lowered pumping speed will occur. There is a big difference of cryopump pumping capacity between non-condensable gases and condensable gases. For instance, the pumping capacity for hydrogen is about 1% of that for nitrogen and argon.

3-1.Pumping Capacity for Condensable Gases

The gases pumped by condensation are ①gases pumped at 80K shield and baffle (mainly H2O) and ②gases pumped at 15K cryopanel (nitrogen, argon, oxygen, etc.)

(1) Pumping Capacity for Water

The pumping speed for gases condensed or adsorbed at 15K cryopanel decreases as the accumulated water frost deposit reduces their conductance by making the gas passages in the pump narrower. When the pumping speed significantly lowered, regeneration is required. There is no clear definition of the pumping speed for water, but it is assumed that the pumped water before regeneration is the pumping capacity for water. Refer to table below for pumping capacity for water.(Note that the unit is in grams(g).)

| Model | Pumping Capacity (g) |

|---|---|

| CRYO-U6H | 40 |

| CRYO-U8H,U8H-U | 90 |

| CRYO-U10PU | 170 |

| CRYO-U12H | 260 |

| CRYO-U16,U16P | 500 |

| CRYO-U20P | 1000 |

| CRYO-U22H | 1400 |

Table 5.Pumping Capacity for Water(as measure)

| (1) Materials which release much water during processing are |

|---|

| Plastic |

| Glass |

| Ceramic |

| (2) Cautions for regeneration at atmosphere with much water are |

|---|

| Melt ice completely when warming up. |

| Do not freeze water when rough pumping. |

| Remove water from inside cryopump completely. |

| Confirm the operation of rotary pump.(Avoid emulsifying of oil.) |

(2)Pumping Capacity for Argon

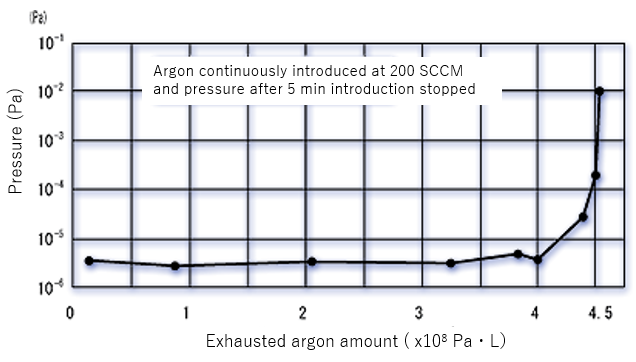

In sputtering process, there is a problem concerning the pumping capacity for argon condensed at 15K cryopanel. If the accumulated argon frost on the external surface of 15K cryopanel becomes thick, it may reach 80K baffle and shield which are both high temperature parts compared to 15K cryopanel. In addition, there is a possibility of insufficient pumping for argon since the temperature of argon frost reached to 80K baffle and shield may become too high to condense argon more than that. The amount of argon, which is pumped previously until then, is called the pumping capacity for argon. Pumping capacity for argon is defined as the amount of previously pumped argon when introduction of argon has stopped, and the pressure after 5 minutes with closing main valve does not drop below 1.3X10-4Pa. Even if the introduction of argon is stopped, the pumping ability will be lost if the pumping capacity for argon has reached its capacity. Figure 3 shows the pressure build up of CRYO-U12HSP. In this figure, argon has been introduced continuously at 200SCCM, and then the pressure 5 minutes after the introduction of argon has stopped was recorded. As you see from the figure, the pressure buildup worsens significantly at 4.3X108 Pa・L, and thus it is assumed that the pumping capacity is 4.3X108 Pa・L. Various cryopump pumping capacity for argon is also shown in Table 6.

Figure 3.Pressure Buildup of CRYO-U®12HSP(Example)

| ModelCRYO- | Pumping Capacity(Pa・L) |

|---|---|

| -U6H | 5.6×107 |

| -U8H,U8H-U | 1.0×108 |

| -U8HSP | 2.5×108 |

| -U10PU | 1.0×108 |

| -U12H | 2.1×108 |

| -U12HSP | 4.3×108 |

| -U16,U16P | 4.3×108 |

| -U20P | 5.8×108 |

| -U22H | 8.1×108 |

| -U30H | 7.8×108 |

3-2.Pumping Capacity for Non-condensable Gases

Non-condensable gases such as hydrogen, helium, and neon are pumped by porous materials attached to inner surface of 15K cryopanel since they will not condense at 10K and will not pumped by the metal surface. Therefore, not only will the capacity be limited to fractions of a monolayer, but the pumping speed will decrease as the surface coverage increases, and the cryopump will lose its pumping ability at last. When the pumping speed for hydrogen drops to 80% of its starting value, ULVAC CRYOGENICS defined the quantity of hydrogen pumped as the pumping capacity for hydrogen. The adsorbent should be kept clean to attain its adsorption ability. Contamination of adsorbent is caused by:

① Adsorption of condensable gas such as air.

② Adsorption of water

③ Adsorption of oil vapor

Adsorption ability may be decreased by adsorbing large quantity of substances above. Air and water can be removed from cryopumps by regeneration while oil vapor cannot. If oil vapor is adsorbed to 15K cryopanel(Adsorption panel), the panel is required to be exchanged. Thus, avoid backflow of oil vapor to the cryopump to maintain its pumping ability for hydrogen.

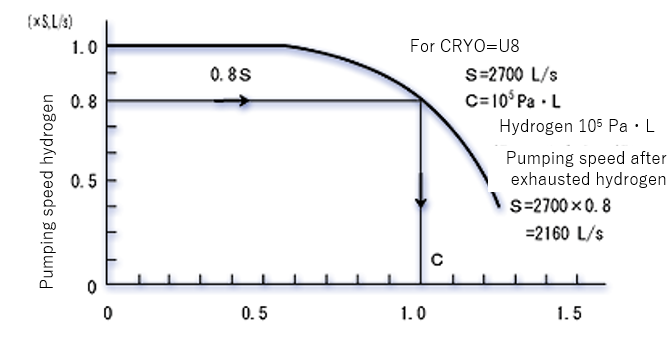

Figure 6-5 shows pumping speed for hydrogen and quantity of pumped hydrogen. In this figure, "S" represents pumping speed and "C" represents pumping capacity. Refer to Table 6-4 for various cryopumps pumping speed and capacity for hydrogen.

Figure4.Pumping Speed and Pumping Capacity for Hydrogen

4.Thermal Load and Maximum Throughput

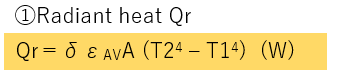

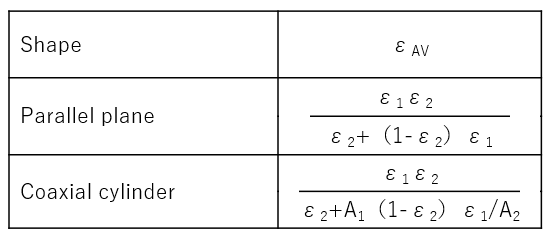

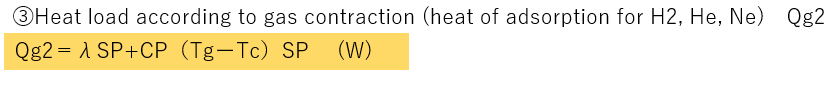

The thermal load to cryopumps is generated not only by heat radiation from the equipment, but also heat from gases such as thermal conductance or heat transfer with condensation. They are given by the following equations:

| σ | :Boltzmann constant 5.67×10-12W/cm2/K4 |

|---|---|

| εAV | :Mean Radiation Rate |

| T1 | :Low Temperature Surface(K) |

| T2 | :High Temperature Surface(K) |

| A | :Heat Receiving Area(cm2) |

A1:Inside A2:Outside

| γ | :Specific Heat Ratio |

|---|---|

| a0 | :Mean Thermal Accommodation Coefficient |

| P | :Pressure(Pa) |

| M | :Molecular Weight |

| T1 | :Low Temperature Surface(K) |

| T2 | :High Temperature Surface(K) |

| A | :Heat Receiving Area(cm2) |

Mean Thermal Accommodation Coefficient a0(A1<A2)![]()

Accommodation Coefficienta1,a2(approx)

| γ | :Condensation Heat(Adsorption Heat for H2, He, and Ne) (W/Pa・L/s) |

|---|---|

| Tc | :Temperature Surface(K) |

| Tg | :Gas Temperature(K) |

| S | :Cryopump Pumping Speed(L/s) SP:(Pa・L/s) |

| P | :Pressure(Torr) |

| Cp | :Mean Specific Heat of Gas(W/(Pa・L/s)/K) |

Thermal load to 1st stage of cold head is from radiation heat and heat conduction of gases, but mainly from radiation heat in normal use except for continuous operation at the same level of 10-1Pa. Thermal load to 2nd stage of cold head is from gas condensation heat, and the maximum throughput is depending on it. The maximum throughput may be reduced as the thermal load to 1st stage increases since the thermal load to 1st stage affects the refrigerating capacity of 2nd stage.

Thus, in case that a large amount of gas is introduced into a cryopump, keep the cryopump clean to avoid radiation heat and also to reduce the thermal load. Generally, a large cryopump requires refrigerators with high-performance refrigerating capacity because thermal load coming from a large inlet is heavy.

The cryopump maximum throughput is defined as the flow rate when temperature of cryopanel becomes 20K under normal radiation heat. In case of cryopumps which have the same sized inlets, the maximum throughput increases as refrigerating capacity increases, or pumping speed increases. For instance, the maximum throughput for CRYO-U16P with R50(cold head) is bigger than that of CRYO-U16 with R20(cold head) because the refrigerating capacity of R50 is bigger than that of R20.

The cryopump maximum working pressure Pmax is given by:

Pmax = Qmax ÷ Smax

Qmax: Maximum Throughput Smax: Pumping Speed

Pmax for argon is in the 10-1Pa, intermediate flow.

The maximum throughput for various cryopumps are shown in Table.

Cryopump Maximum Throughput

| Argon (Pa・L/s) |

Hydrogen (Pa・L/s) |

|

|---|---|---|

| CRYO-U6H | 1.1×103 | 1.1×102 |

| CRYO-U8H,U8H-U,U8HSP | 1.2×103 | 2.4×102 |

| CRYO-U10PU | 8.0×102 | 1.5×102 |

| CRYO-U12H,U12HSP | 2.0×103 | 4.1×102 |

| CRYO-U16 | 1.4×103 | 4.1×102 |

| CRYO-U16P | 1.6×103 | 4.5×102 |

| CRYO-U20P | 1.1×103 | 5.0×102 |

| CRYO-U22H | 4.1×103 | 1.3×103 |

| CRYO-U30H | 2.7×103 | 7.4×102 |

5.Crossover

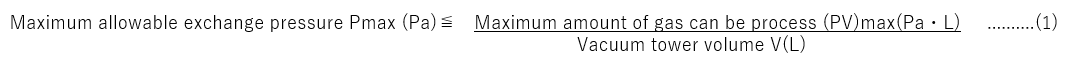

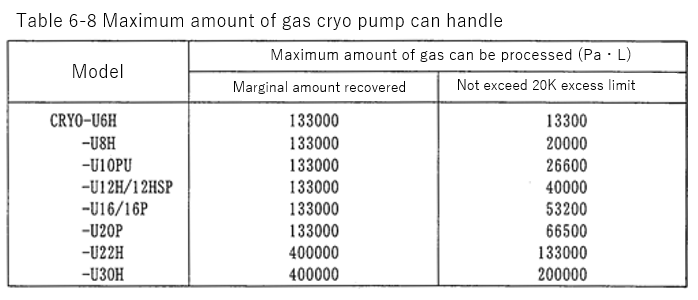

Crossover is defined as the pressure inside the vacuum chamber(roughing pressure) when switching from rough pumping to cryopumping by opening the main valve. The maximum permissible roughing pressure is called the maximum permissible crossover pressure. Cryopumps start pumping operation with opening the main valve, and after pumping a certain amount of gases they are required to be regenerated by warming up and discharging pumped gases. The maximum permissible crossover pressure is given by:

The maximum amount of gas which can be pumped should be a evacuation limit value for cryopumps to recover the pumping ability (in general, temperature of cryopanel is over 20K). However, for safety reasons, the actual maximum permissible cryossover pressure is a half of the value given by the calculation above. In addition, if you take more safety measures, the maximum permissible crossover pressure should be within the value before the temperature of cryopanel exceeds 20K. The maximum amount of gas which can be pumped is depending on the thermal load to cryopump and amount of gases condensed inside cryopump.

Use Table 6-8 as a measuring of the maximum amount of gas pumped for air.

For example, in case of U8H, the maximum permissible crossover pressure(Pmax) for a vacuum chamber of 100L is:

Pmax ≦133000Pa・L/100L=1330Pa

Thus, the roughing pressure is below 1330Pa. For safety reasons, it shall be 665Pa.

For more safety measures(not to exceed 20K), take the value on the right column, then:

P= 20000/100 =200Pa

In case of large volume of chamber and roughing pressure of 40Pa or below, take special measures such as prevention of oil backflow, use of large cryopumps, and use of additional cryopumps to keep roughing pressure at 40Pa or more.

6.Ultimate Pressure

When there is no incoming gas into cryopump, the ultimate pressure for condensable gases is given by the vapor pressure and condensation coefficient(hypothetically 1 in here) for each gas as follows:

Pg=Ps(Tg/Ts)1/2

| Ts | :Temperature of Cryosurface 10~20K |

|---|---|

| Ps | :Vapor Pressure at Temperature(Ts)(Mean Adsorption Pressure for H2)(Pa) |

| Tg | :Temperature of Gas ~300K |

Figure 6-6 shows the ultimate pressure for nitrogen at 10 to 20K. In this figure, nitrogen is chosen because the vapor pressure of nitrogen has the highest vapor pressure among the condensable gases. Generally, temperature of cryopanel drops to 10 to 12K or around without thermal load. Thus, we can ignore the adsorption equilibrium pressure(Pa) from a practical point because pressure from vapor pressure is below 20-21Pa. The ultimate pressure for hydrogen, non-condensable gas, is depending on the mean adsorption pressure. As you see in Figure 6-7, the activated charcoal attached to cryopumps has high adsorption ability for hydrogen. In addition, you may ignore the mean adsorption pressure(Pa) for hydrogen since the amount of pumped hydrogen is very little in ultra-high vacuum atmosphere.

For example, When operating U8H(SH2O=2700 L/s) at 1.3X10-8Pa for one month, the amount of hydrogen adsorbed is : Q=1.3x10-8x2700x30x24x3600=91Pa・L

Therefore, the ultimate pressure of cryopump is determined by balancing with the amount of incoming gases and pumping speed of cryopumps. Generally, the ultimate pressure is measured with closing cryopump by a blank flange to minimize the amount of the incoming gas. In addition, the ultimate pressure differs widely according to the specifications(for normal use and ultra-high vacuum use), roughing pressure, and operation with or without baking. When rough pumping to 40Pa with standard O-ring sealing, and no-baking, the ultimate pressure after approx. 12 hours will be (1~4)X10-6Pa. Figure 6-7 shows a test result of the residual gas compositions after baking and without baking. Also, Table 6-9 shows the estimation of ultimate pressure for a cryopump. After baking completely, cryopumps can attain ultra-high vacuum atmosphere around 10-10Pa with ultra-high vacuum specifications. The ultimate pressure of the system is depending on outgas from the system.(P=Q/S)

Figure 6.Ultimate Pressure

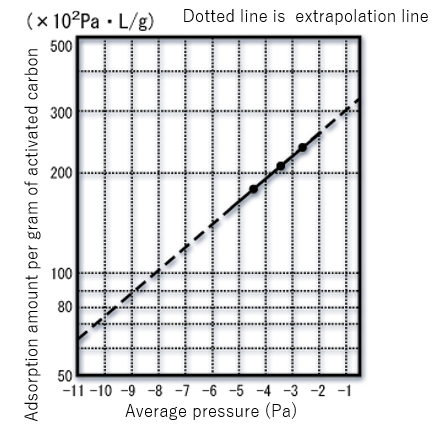

Adsorption Isotherm of Acctivated Charcoal for H2

Cryopump Ultimate Pressure(Estimation)

| TYPE | Roughing Pressure(Pa) | Baking | Ultimate Pressure(Pa) |

|---|---|---|---|

| Standard | 40 40 |

なし (100~150℃)×(3~10h) |

(1~4)×10-6 (1~4)×10-7 |

| Ultra-high | 10-2~10-3 10-2~10-4 10-2~10-3 |

なし (200~220℃)×(3~8h) (200~220℃)×約20h |

10-8 10-9 10-10 |

Principle of Refrigerator Operation

1.Principle of Refrigeration

Figure 1.Principle of Refrigeration

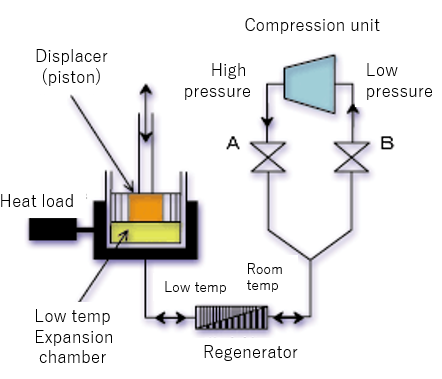

2.Refrigeration Cycle for Cryopumps

Two types of refrigeration cycle for cryopumps operation are in common use: the Gifford-McMahon cycle(G-M cycle) and the Modified-Solvay cycle(M-Solvay cycle). G-M cycle ensures more reliable operation, thus becomes much popular for cryopumps refrigeration cycle. ULVAC CRYOGENICS employs G-M cycle refrigerator for CRYO-U cryopumps.

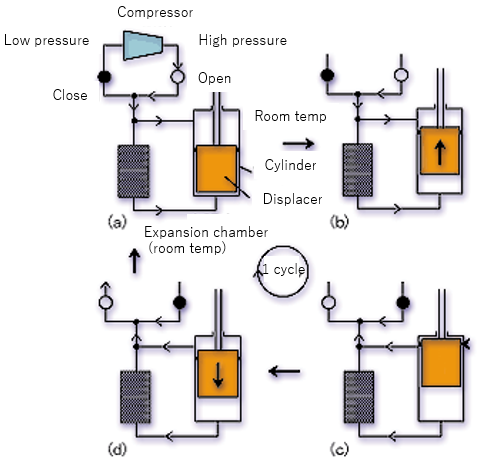

2-1.G-M(Gifford-McMahon) Cycle

G-M cycle was developed by Gifford in the late 1950's. The displacer in this refrigeration cycle are usually mechanically driven, or pneumatically driven. G-M cycle is very efficient and reliable refrigeration cycle which operates at slow speed and gives a little damage to the seal used inside refrigerator. In this manual, the mechanical driven refrigeration cycle used in CRYO-U® cryopumps will be explained.

A The displacer is first positioned at the bottom of the cylinder, the low pressure valve closes and high pressure valve opens.

↓

(a)The compressed helium is introduced into the cylinder.

↓

B Pressure inside the cylinder increases.

↓

(b)The displacer is moved up. The cooled gas fills the space beneath the piston.

↓

C The low temperature part attains maximum volume. The high pressure valve closes and exhaust low-pressure valve opens.

↓

(c)The compressed helium passed through the regenerator into the lower part of the cylinder. While passing through the regenerator the helium is cooled because it expands.

↓

D The low temperature part attains the lowest pressure

↓

(d)The displacer is moved down and the expanded helium pumped by the compressor through the open low pressure valve.

↓

A Finally the low pressure valve is closed and the cycle repeated.

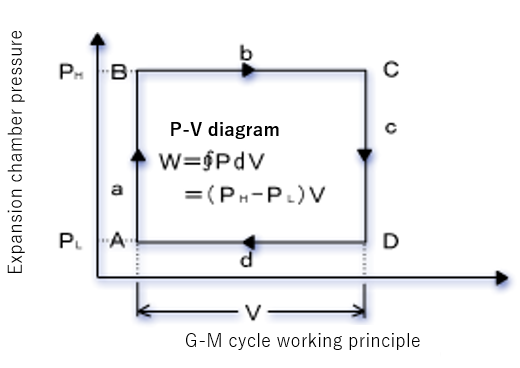

As shown in Fig. 2, the ideal P-V diagram of G-M cycle shows a square pattern. Ideal refrigerating capacity (Q ideal) is given by the following equation where the period of one cycle is taken at t second, Q ideal = W/t

The actual refrigerator has two stage construction to achieve extreme low temperature below 15K. Also, for cryopumps, usually the regenerator is placed inside the displacer for simplification. Two stage refrigerator is designed to reduce a load to 1st and 2nd seals with differential pressure so that it performs long-period, highly reliable operation.

Fundamentals of Vacuum Pumps (High Vacuum)

- Screw Pump

- Multi-Stage Roots Vacuum Pump

- Dry Scroll Vacuum Pump

- Dry Diaphragm Vacuum Pump

- Dry Rocking Piston Vacuum Pump

- Dry Rotary Vane Vacuum Pump

- Oil Rotary Vacuum Pump

- Mechanical Booster Pump

- Cryopumps

- Turbomolecular Pump

- Ion Pump

- Titanium Sublimation Pump

- Sorption Pump

- Diffusion Pump

- Ejector Pump

HOW TO

- Vacuum Tech Basics

- Fundamentals of Vacuum Pumps (Low to Medium Vacuum)

- Fundamentals of Vacuum Pumps (High Vacuum)

- Fundamentals of Vacuum Valves

- Fundamentals of Vacuum Gauges

- Fundamentals of Quartz Crystal Oscillation Type Deposition Controller

- Fundamentals of Leak Detection

- Fundamentals of High-Speed Spectroscopic Ellipsometer

- Fundamentals of Gas Analyzer (Process Gas Monitor)

- The Others

- How to Choose The Best Products

- Old Models vs. New Models

- Troubleshooting