Fundamentals of Vacuum Pumps (High Vacuum)

Mechanical Booster Pump

What is a Mechanical Booster Pump?

A mechanical booster pump dramatically increases pumping speed.

A roughing pump such as an oil rotary vacuum pump and a dry pump etc. combined with the mechanical booster pump, increases its pumping speed at the pressure range decreased.

Mechanical Booster Pump Applications:

- Semiconductor Processes

- Vacuum Distillation

- Vacuum Packaging

- Degassing

- Thin Films

- Vacuum Metallurgy

- Low-Density Wind Tunnel Experiments

- Space Development

- Vacuum impregnation

- Vacuum Drying

Feature

| Advantage | Disadvantage |

| Pumping speed skyrockets from 10KPa to 0.1KPa | Backflow |

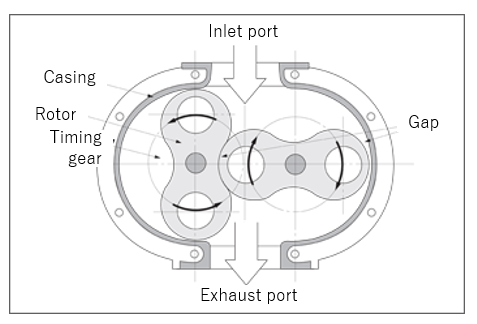

How Mechanical Booster Pump Works

Two cocoon-shaped rotors set each side's driving gear in a casing rotate synchronously in opposite directions. Gas from an inlet port is sealed between the casing and the rotor. The rotor pumped the gas to the exhaust port, and an auxiliary pump at the rear stage discharges the gas into the atmosphere.

Rotors don't contact each other and the casing. They rotate to transfer the gas while keeping a slite gap of only 0.1mm~0.3mm, so lubricating oil is not required in the rotor chamber.

Fundamentals of Vacuum Pumps (High Vacuum)

- Screw Pump

- Multi-Stage Roots Vacuum Pump

- Dry Scroll Vacuum Pump

- Dry Diaphragm Vacuum Pump

- Dry Rocking Piston Vacuum Pump

- Dry Rotary Vane Vacuum Pump

- Oil Rotary Vacuum Pump

- Mechanical Booster Pump

- Cryopumps

- Turbomolecular Pump

- Ion Pump

- Titanium Sublimation Pump

- Sorption Pump

- Diffusion Pump

- Ejector Pump

HOW TO

- Vacuum Tech Basics

- Fundamentals of Vacuum Pumps (Low to Medium Vacuum)

- Fundamentals of Vacuum Pumps (High Vacuum)

- Fundamentals of Vacuum Valves

- Fundamentals of Vacuum Gauges

- Fundamentals of Quartz Crystal Oscillation Type Deposition Controller

- Fundamentals of Leak Detection

- Fundamentals of High-Speed Spectroscopic Ellipsometer

- Fundamentals of Gas Analyzer (Process Gas Monitor)

- The Others

- How to Choose The Best Products

- Old Models vs. New Models

- Troubleshooting