Fundamentals of Vacuum Pumps (High Vacuum)

Ejector Pump

What is an Ejector Pump?

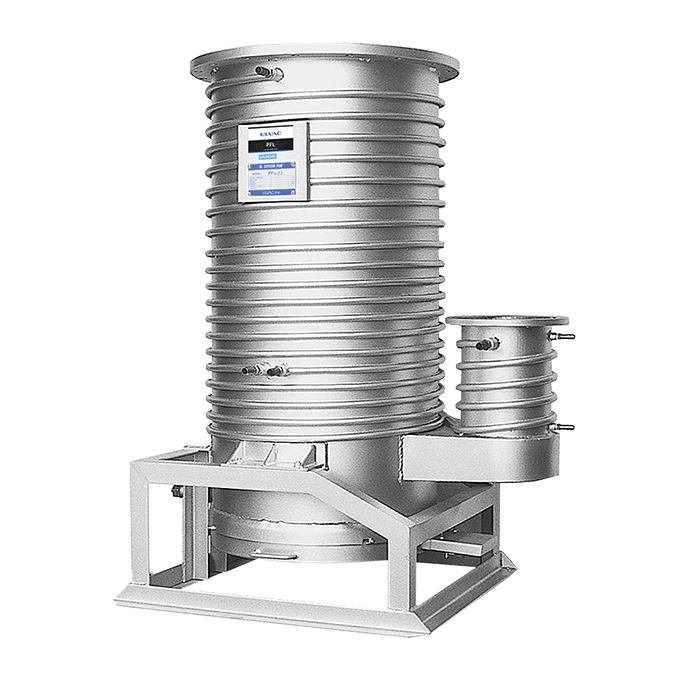

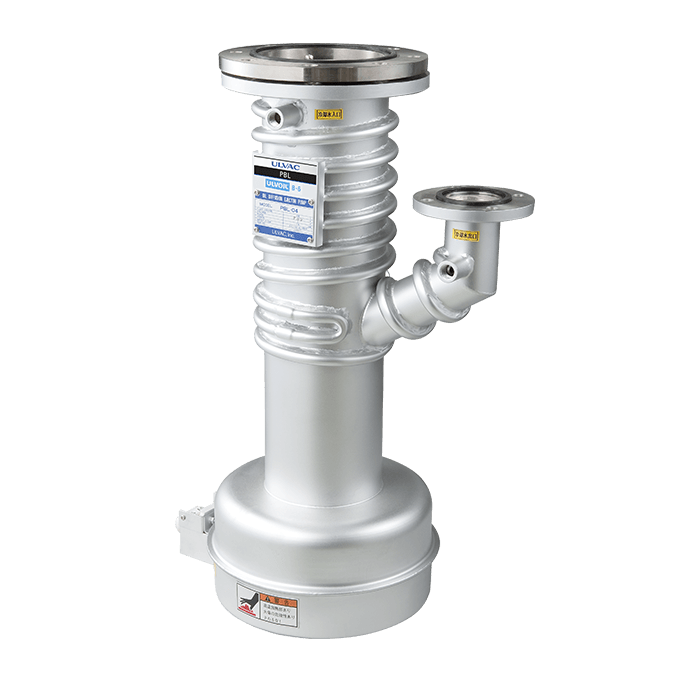

An ejector pump ejects vapor or steam, such as an oil diffusion pump.

A steam ejector pump is one of the most versatile vacuum pumps in industrial ways. Its advantages over mechanical vacuum pumps are durability, low cost, and more. This article picks an oil ejector pump up. Other types, for instance, steam ejector type and water ejector type, are on other articles. Check them up!

Ejector Pump's Applications:

- Vacuum degassing equipment for steel

- Distillation equipment

- Polymerization equipment

Features

The steam ejector pump works by water vapor fluid. It has lesser moving parts than the mechanical vacuum pump, so more durable and cheaper.

The water ejector pump works by water fluid. This pump doesn't work without other combination pumps such as oil rotary vacuum pumps and so on.

| Advantage | Disadvantage |

| Very durable due to no moving parts. | Low energy efficiency. |

How Ejector Pump Works

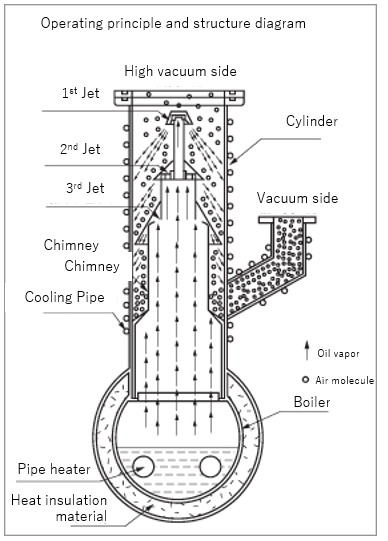

The ejector pump consists of the main body, a heating section, and a jet section. The working oil is heated in the boiler and turns into steam. The steam is ejected from jet sections of each stage at high speed. The gas on the high vacuum side is entrained in the ejected steam (diffusion) and transported from the upper jet section to the lower jet section, then exhausted from the exhaust port to the fore pump side while being compressed.

The ejected steam is cooled and condensed on the inner wall of the main body and returns to the boiler. This pumps exhausts by repeating this action.

Fundamentals of Vacuum Pumps (High Vacuum)

- Screw Pump

- Multi-Stage Roots Vacuum Pump

- Dry Scroll Vacuum Pump

- Dry Diaphragm Vacuum Pump

- Dry Rocking Piston Vacuum Pump

- Dry Rotary Vane Vacuum Pump

- Oil Rotary Vacuum Pump

- Mechanical Booster Pump

- Cryopumps

- Turbomolecular Pump

- Ion Pump

- Titanium Sublimation Pump

- Sorption Pump

- Diffusion Pump

- Ejector Pump

HOW TO

- Vacuum Tech Basics

- Fundamentals of Vacuum Pumps (Low to Medium Vacuum)

- Fundamentals of Vacuum Pumps (High Vacuum)

- Fundamentals of Vacuum Valves

- Fundamentals of Vacuum Gauges

- Fundamentals of Quartz Crystal Oscillation Type Deposition Controller

- Fundamentals of Leak Detection

- Fundamentals of High-Speed Spectroscopic Ellipsometer

- Fundamentals of Gas Analyzer (Process Gas Monitor)

- The Others

- How to Choose The Best Products

- Old Models vs. New Models

- Troubleshooting