Fundamentals of Vacuum Pumps (High Vacuum)

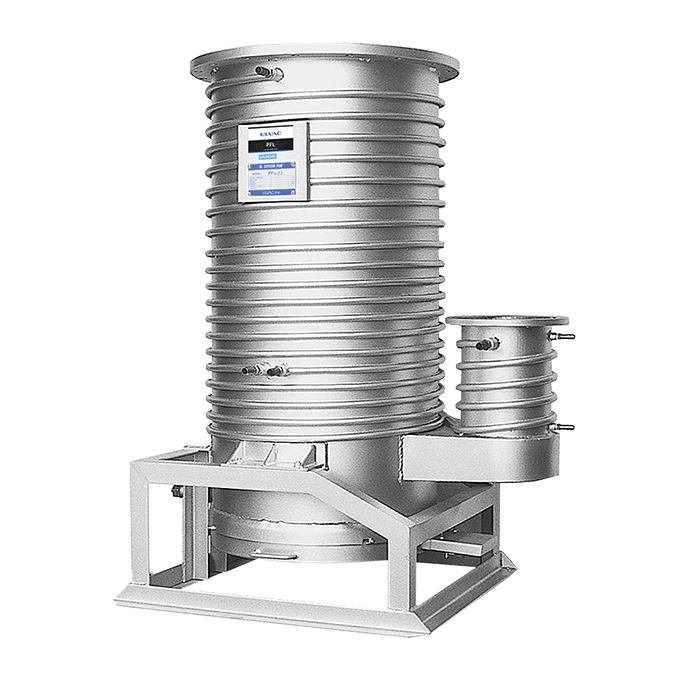

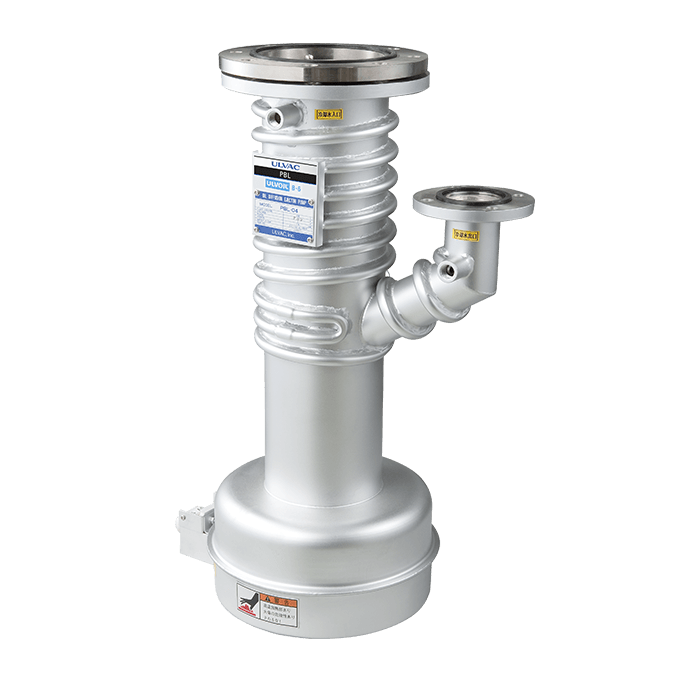

Diffusion Pump

What is a Diffusion Pump?

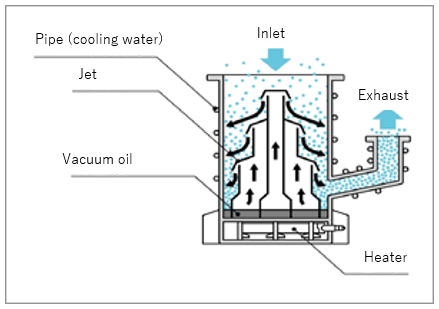

This pump exhausts gas molecules by imparting momentum to the gas molecules, which enter from the inlet port due to diffusion phenomena, toward the exhaust port by using high-speed and high-density oil vapor jet flow from a nozzle. The jet flow also prevents gas molecules from flowing back into the inlet port.

Diffusion Pump's Application:

- FPD manufacturing equipment

- Semiconductor manufacturing equipment

- Vacuum distillation

- Purification degassing

- Sterilization

- Drying

- Dehydration

- Disinfection

Feature

The diffusion pump consists of a boiler heating oil and generating steam, an umbrella-shaped nozzle to jet the steam in a direction, and cold side walls to condense the steam. Despite such a simple structure, the pumping speed is quite high. This pump does not work alone, and it has to combine with oil rotary vacuum pumps.

| Advantage | Disadvantage |

| Simple structure and high pumping speed/ | Presence of oil vapor flowing back from the nozzle to the high vacuum side. |

How Diffusion Pump Works

The oil at the bottom of the pump is heated and turns into vapor. The vapor is ejected from the jet at supersonic speed, pushed out from the upper jet to the lower, and heading toward the exhaust port. The emitted oil vapor is cooled and condensed on the inner wall, turning into oil, and returns to the heating section.

Fundamentals of Vacuum Pumps (High Vacuum)

- Screw Pump

- Multi-Stage Roots Vacuum Pump

- Dry Scroll Vacuum Pump

- Dry Diaphragm Vacuum Pump

- Dry Rocking Piston Vacuum Pump

- Dry Rotary Vane Vacuum Pump

- Oil Rotary Vacuum Pump

- Mechanical Booster Pump

- Cryopumps

- Turbomolecular Pump

- Ion Pump

- Titanium Sublimation Pump

- Sorption Pump

- Diffusion Pump

- Ejector Pump

HOW TO

- Vacuum Tech Basics

- Fundamentals of Vacuum Pumps (Low to Medium Vacuum)

- Fundamentals of Vacuum Pumps (High Vacuum)

- Fundamentals of Vacuum Valves

- Fundamentals of Vacuum Gauges

- Fundamentals of Quartz Crystal Oscillation Type Deposition Controller

- Fundamentals of Leak Detection

- Fundamentals of High-Speed Spectroscopic Ellipsometer

- Fundamentals of Gas Analyzer (Process Gas Monitor)

- The Others

- How to Choose The Best Products

- Old Models vs. New Models

- Troubleshooting