Fundamentals of Vacuum Pumps (High Vacuum)

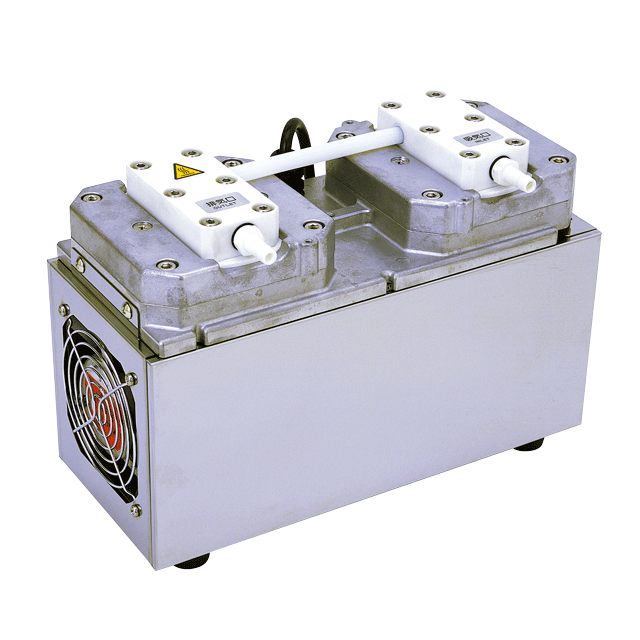

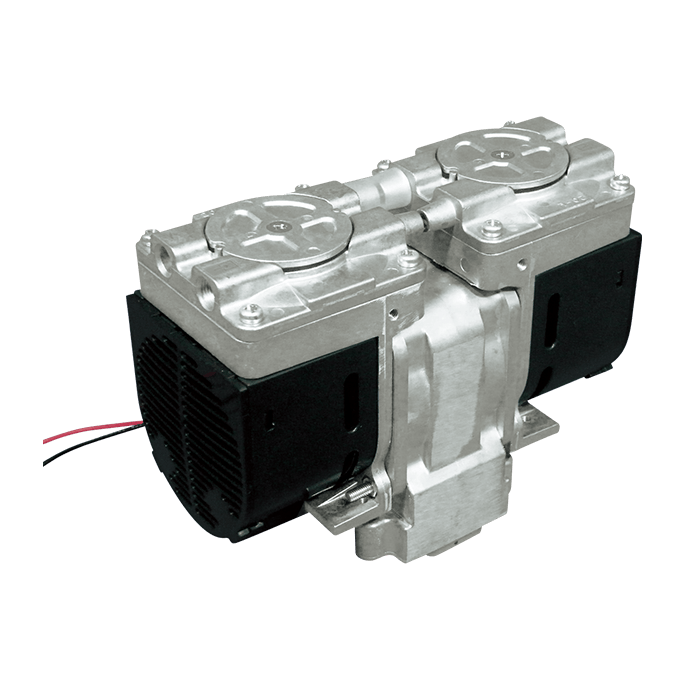

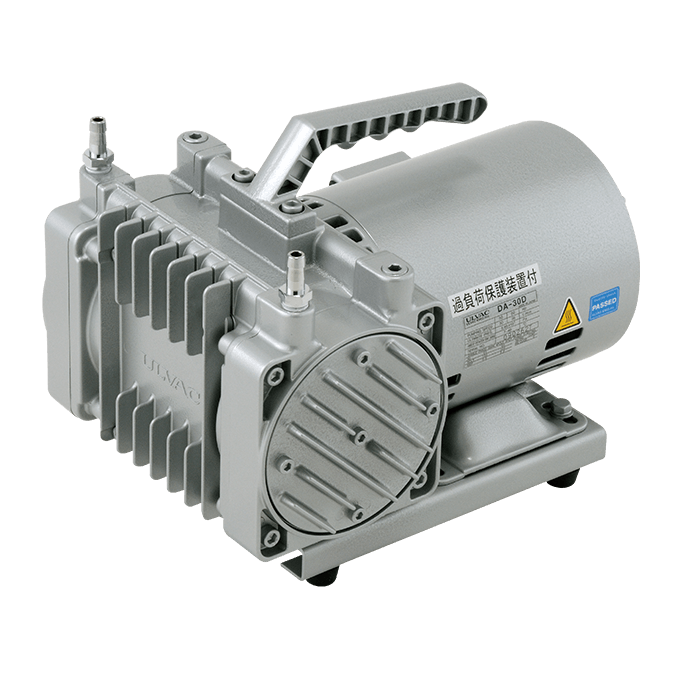

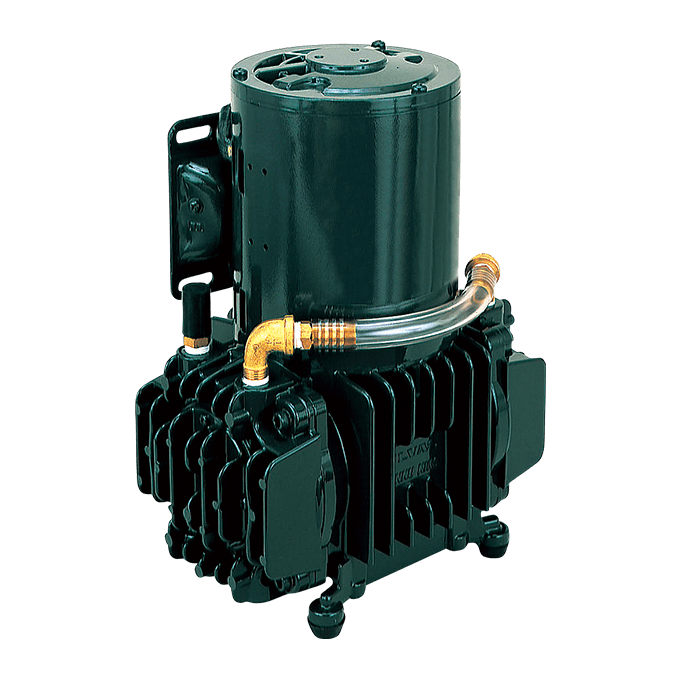

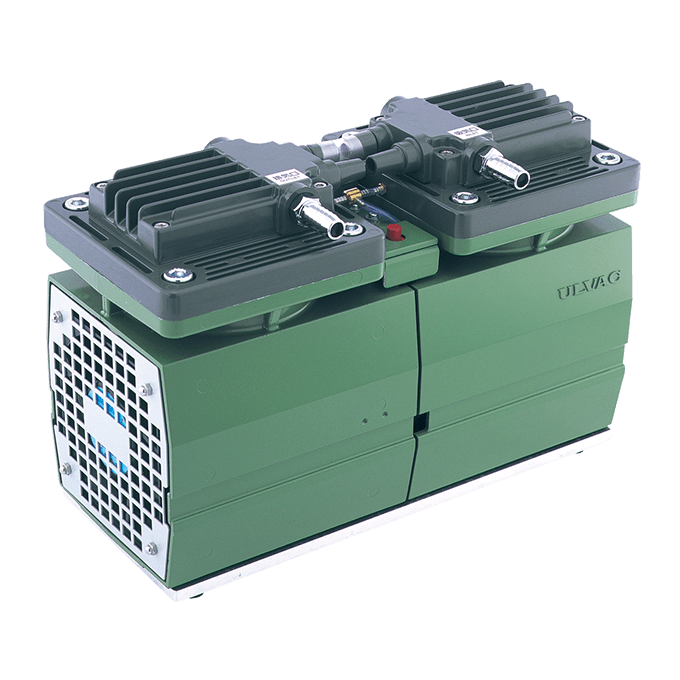

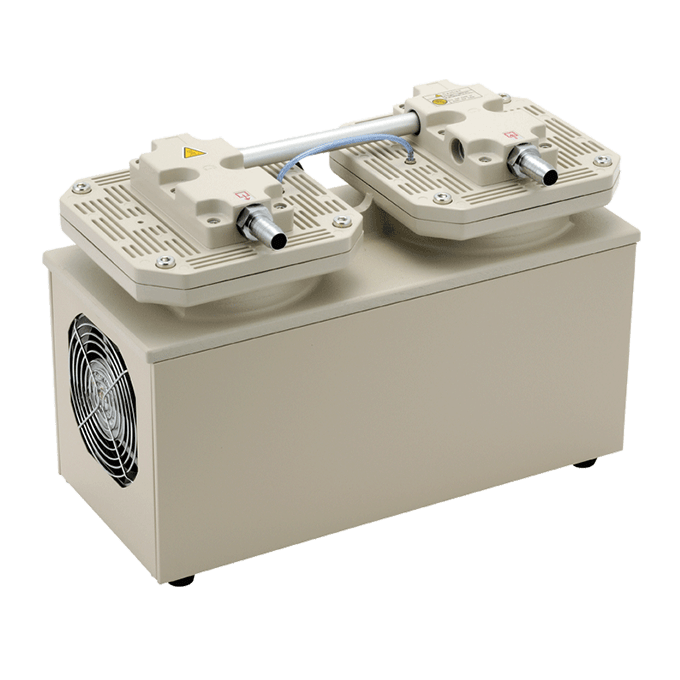

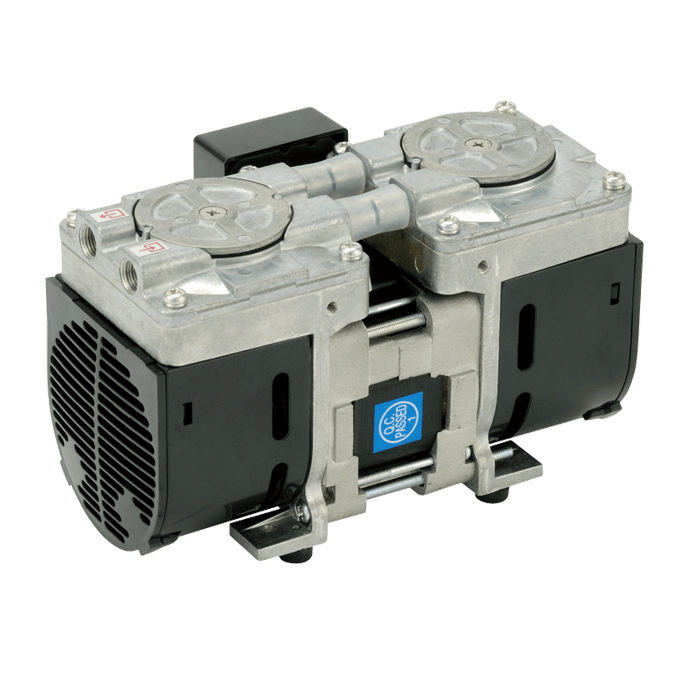

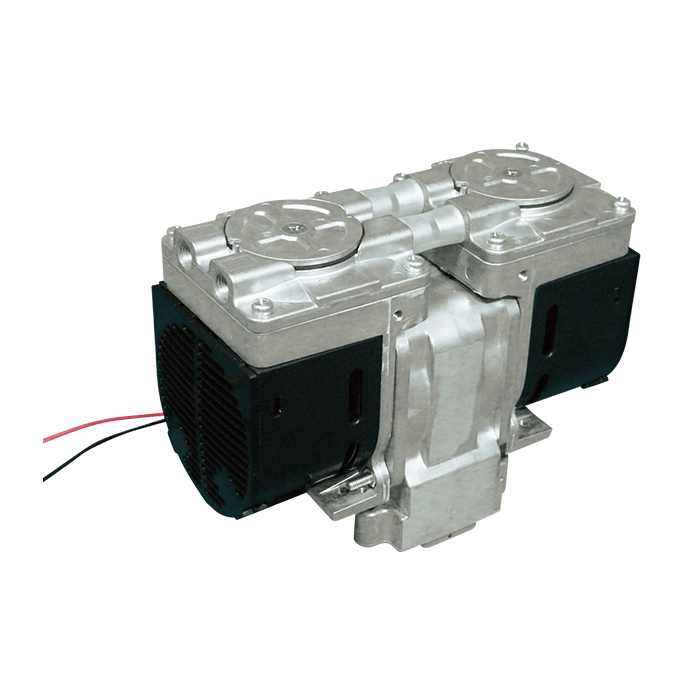

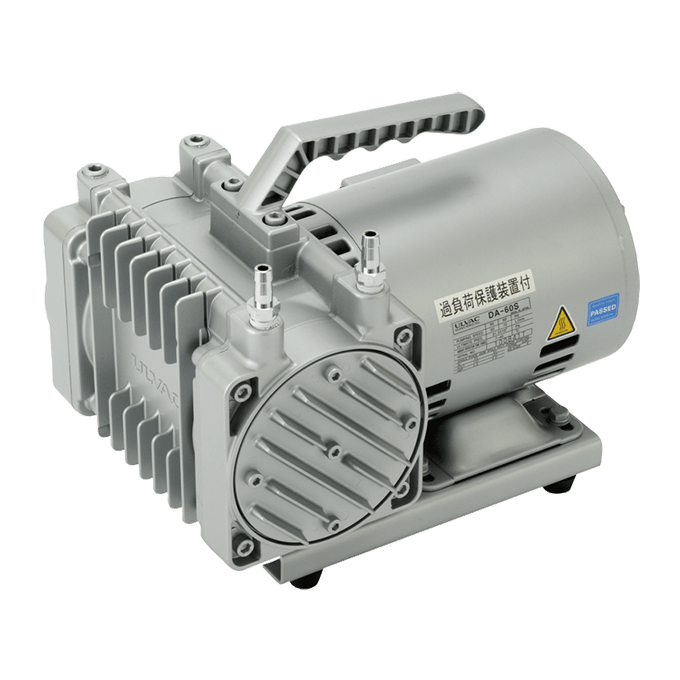

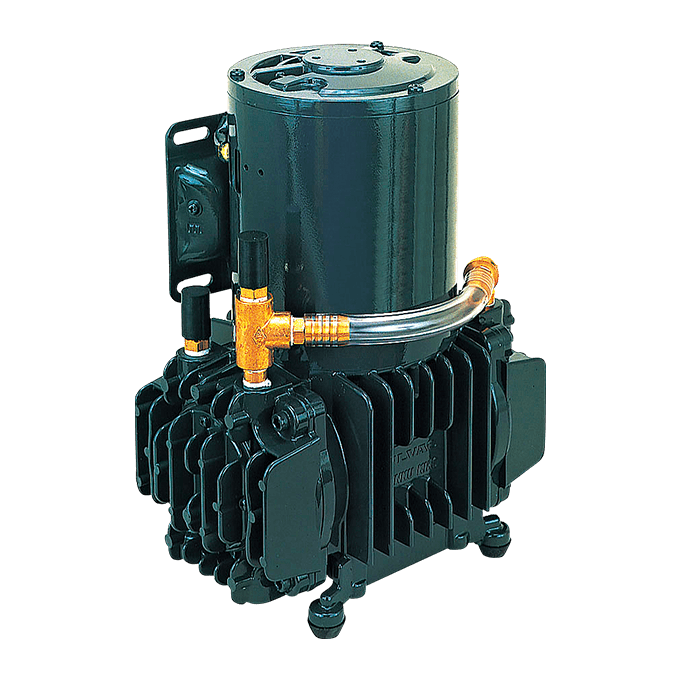

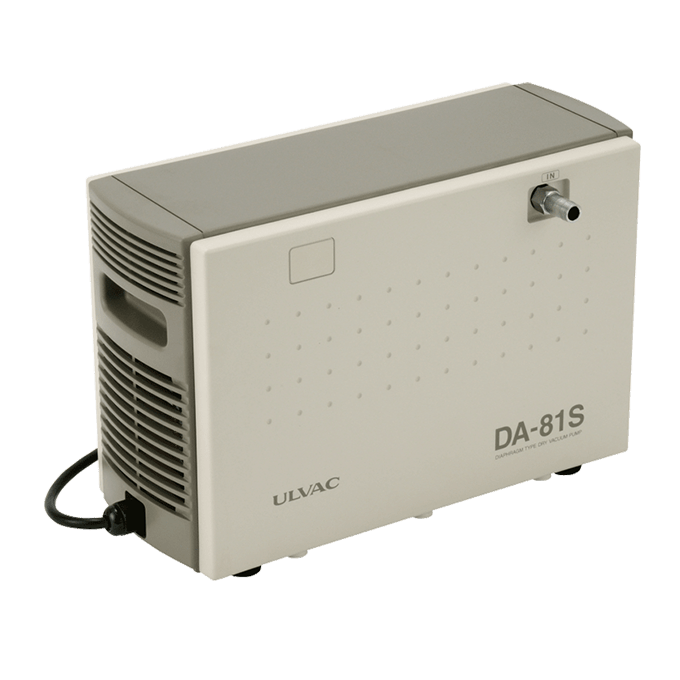

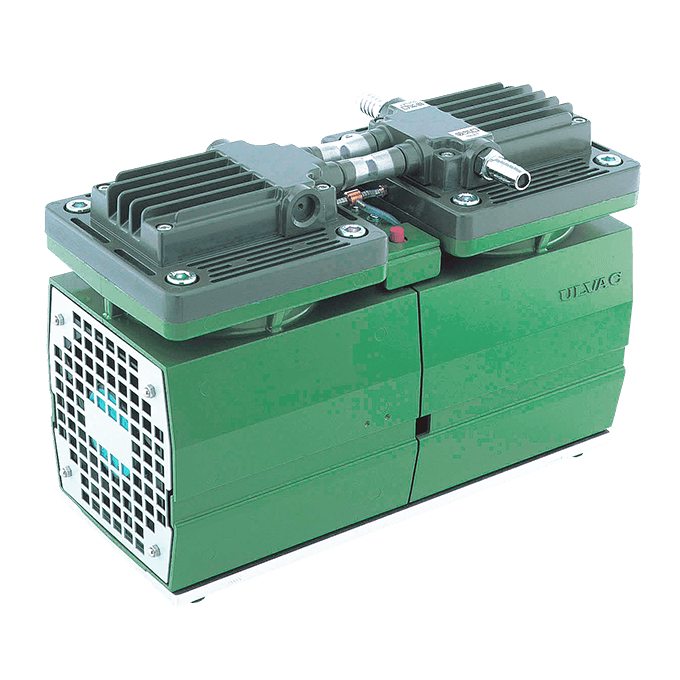

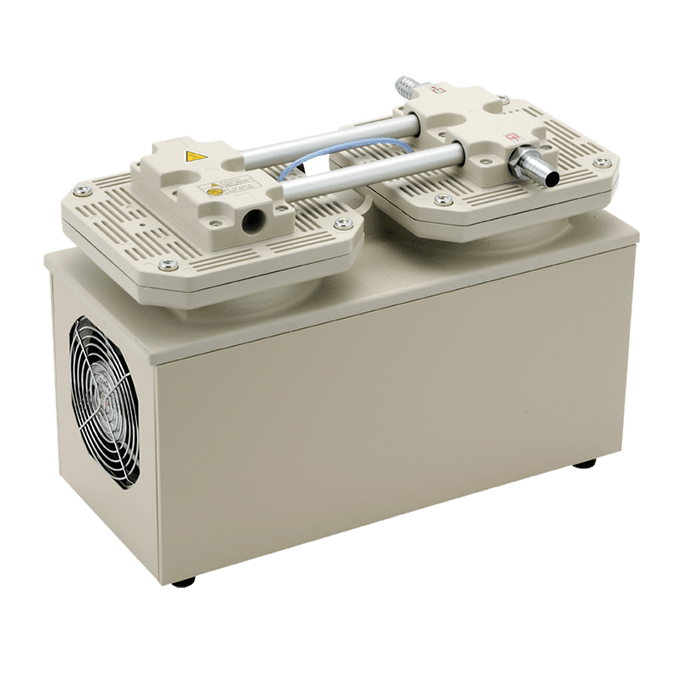

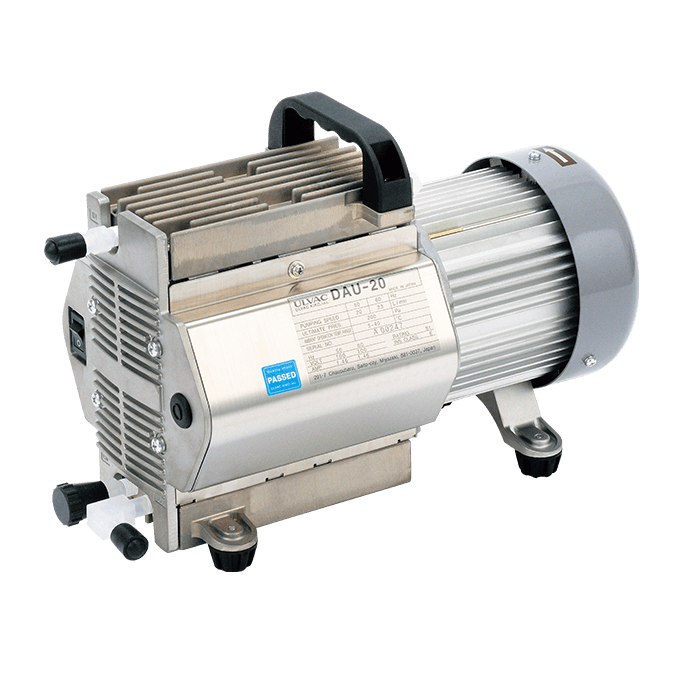

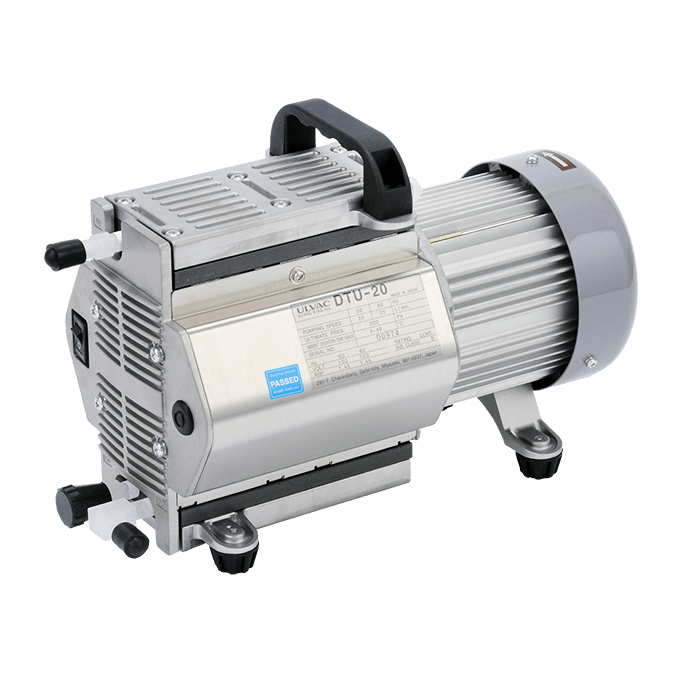

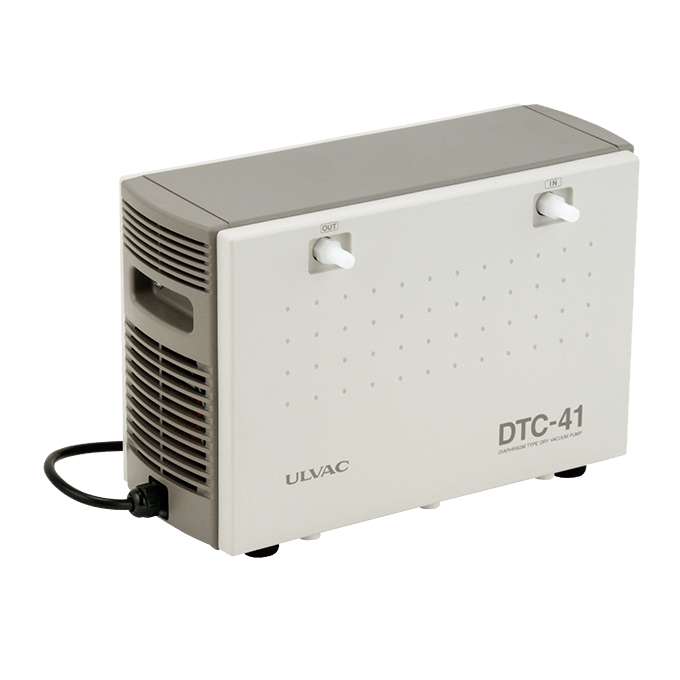

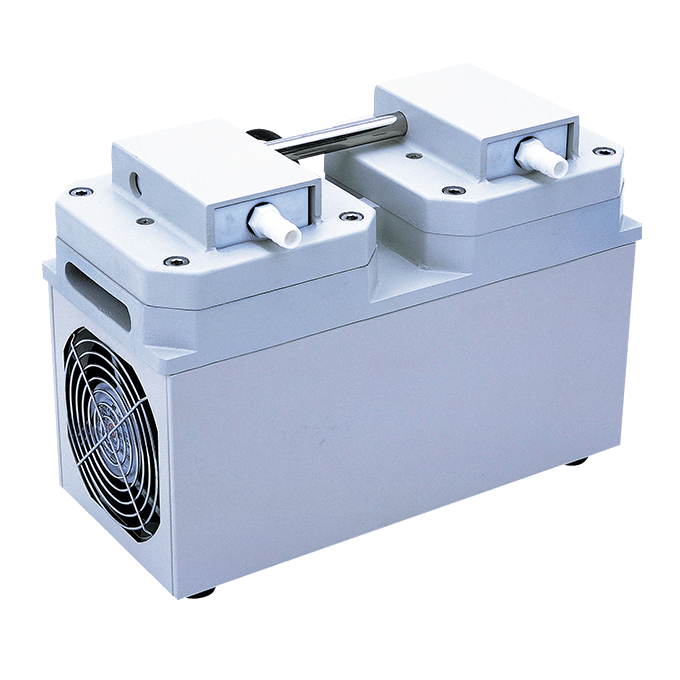

Dry Diaphragm Vacuum Pump

What is Dry Diaphram Vacuum Pump?

It is a mechanical vacuum pump without oil or liquid. Particularly, it is perfect for requiring a clean atmosphere that is not contaminated by oil vapor. Demand for diaphragm vacuum pumps has been growing rapidly due to the highly developing semiconductor manufacturing and electronics equipment industries.

It is used in various applications such as IC wafer suction equipment, vacuum chucks, film suction equipment, automatic machines, packaging machines, optical machines, vacuum tweezers, medical equipment, printing machines.

Gas is transported by the movement of a diaphragm attached to a stem fixed to an eccentric rotating shaft. This type has a relatively small capacity due to the limited movement of the diaphragm.

Diaphragm vacuum pump Applications:

- Vacuum pumping

- Vacuum concentration

- Filtration

- Degassing and Defoaming

- Vacuum chuck

- Film suction

- Packaging machines

- Optical machines

- Vacuum tweezers

- Medical equipment

- Printing machines.

Features

The dry diaphragm pumps do not require oil or liquid, so it is not contaminated by oil vapor. It's the perfect pump for a clean atmosphere.

| Advantage | Disadvantage |

| No oil, perfect for clean exhaust. | It cannot reach a high vacuum. |

How Dry Diaphragm Vaccum Pump Works?

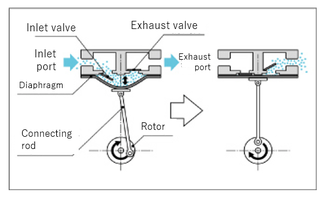

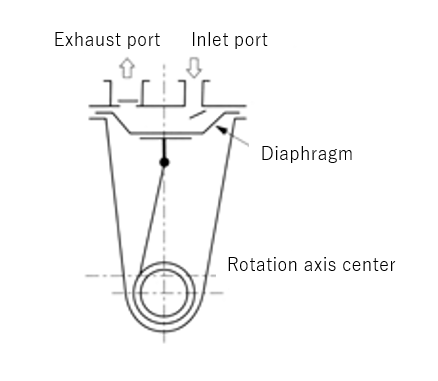

Rotation of the eccentric axis (rotor) transfers power to the diaphragm through the connecting rod. The diaphragm moves up and down repeatedly to transport gas from the inlet port to the exhaust port, allowing clean exhaust. Also, valves are installed at each port to allow air to flow in the same direction constantly.

Dry Diaphragm Vacuum Pump's Structure

Fundamentals of Vacuum Pumps (High Vacuum)

- Screw Pump

- Multi-Stage Roots Vacuum Pump

- Dry Scroll Vacuum Pump

- Dry Diaphragm Vacuum Pump

- Dry Rocking Piston Vacuum Pump

- Dry Rotary Vane Vacuum Pump

- Oil Rotary Vacuum Pump

- Mechanical Booster Pump

- Cryopumps

- Turbomolecular Pump

- Ion Pump

- Titanium Sublimation Pump

- Sorption Pump

- Diffusion Pump

- Ejector Pump

HOW TO

- Vacuum Tech Basics

- Fundamentals of Vacuum Pumps (Low to Medium Vacuum)

- Fundamentals of Vacuum Pumps (High Vacuum)

- Fundamentals of Vacuum Valves

- Fundamentals of Vacuum Gauges

- Fundamentals of Quartz Crystal Oscillation Type Deposition Controller

- Fundamentals of Leak Detection

- Fundamentals of High-Speed Spectroscopic Ellipsometer

- Fundamentals of Gas Analyzer (Process Gas Monitor)

- The Others

- How to Choose The Best Products

- Old Models vs. New Models

- Troubleshooting